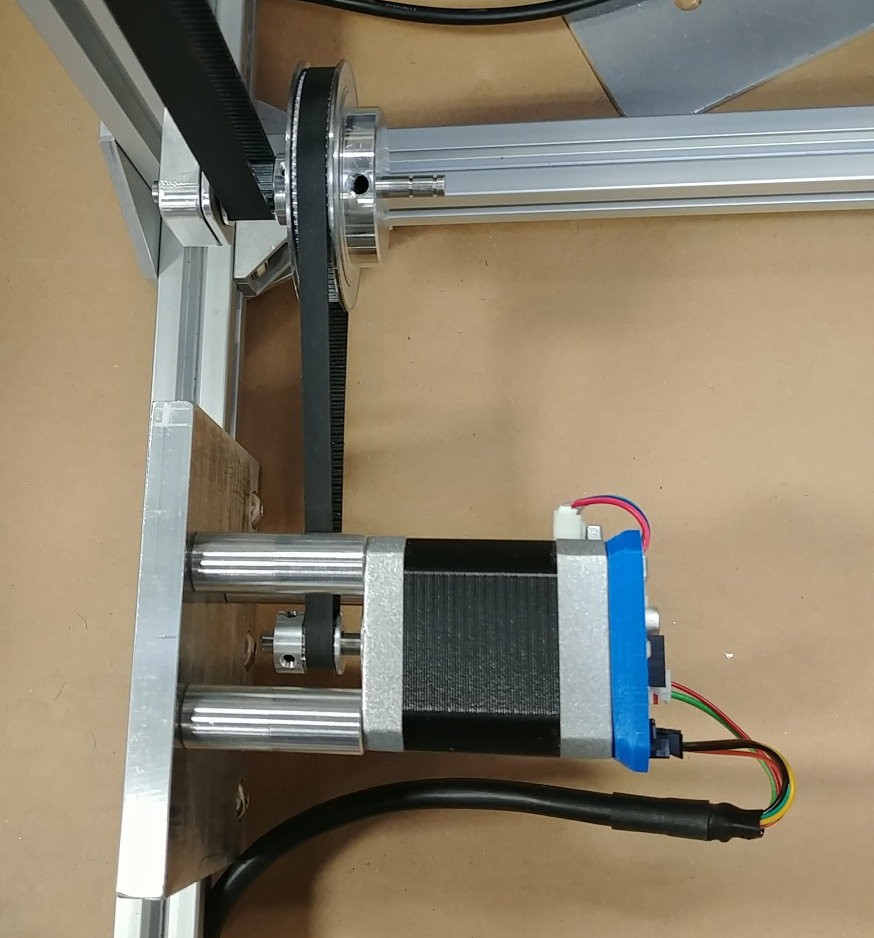

Z-axis pulley division:

- 200 step per revolution motor (1.8°)

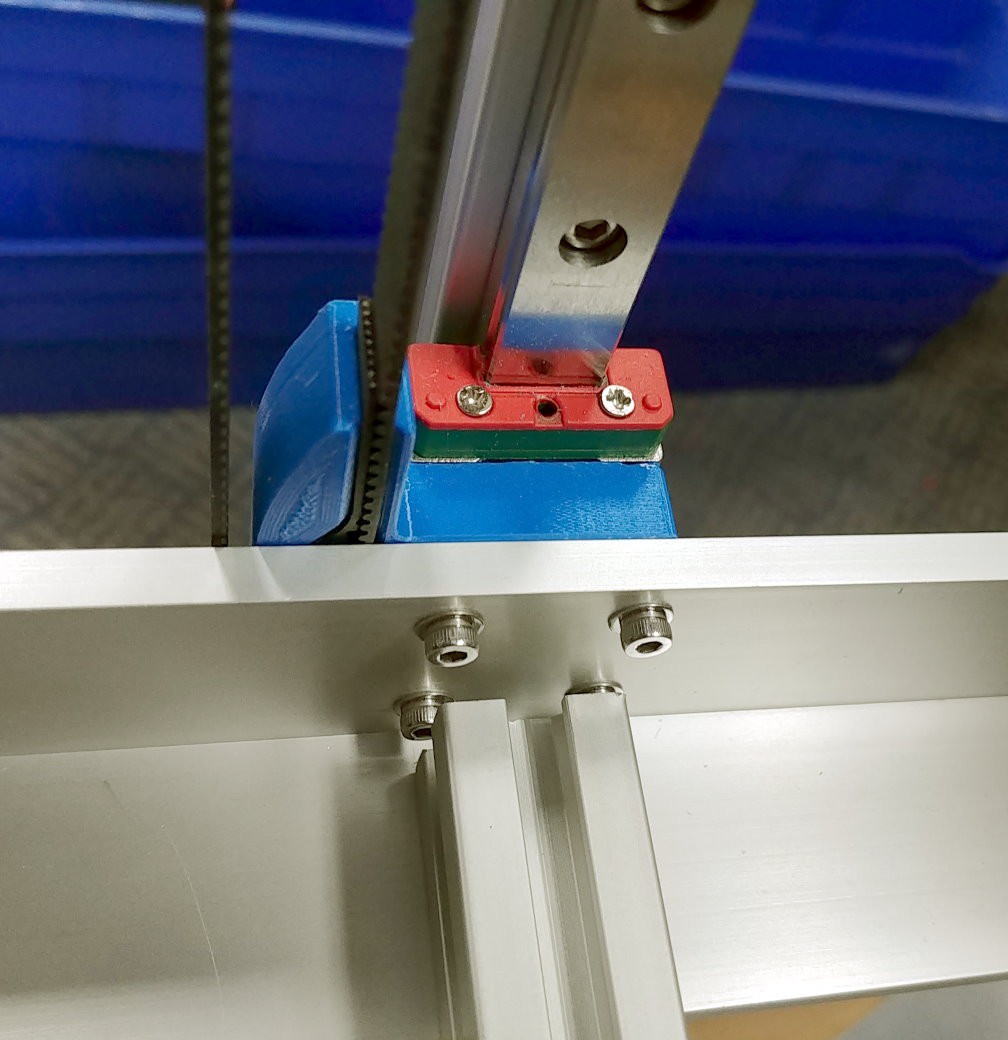

- Stepper shaft has 16T pulley -> driving 80T pulley -> driving 20T pulley -> connected to belt

- Reduction = 5:1

- Final 20T pulley pitch diameter = 12.73mm (reference)

- 12.73mm * pi / 200 / 5 = 0.03999mm

Each full step should move z-axis 0.03999mm (a number that divides into 0.2mm would be better, but it should be close enough).

Can be divided down with microsteps 1/2, 1/4, 1/8, 1/16: 19.996, 9.998, 4.999, 2.4995um

6mm belt on first stage, then wider 10mm belt on second stage for higher load:

- 6mm = 2.8kg working, 56kg breaking strength

- 10mm = 4.4kg working, 88kg breaking strength

Hopefully bed weight will be <4.4kg.

Thomas

Thomas

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.