As promised, a detailed description of what is wrong with those switches and why both Flounder and Turbot are failures thank to them. I just want to say that this is a problem I only have with the sunken low-profile switches from Kailh specifically. I have used their other low-profile switches in a number of different keyboards, and only have good things to say about them. I don't know if this problem is specific to the batch I received or generally to all sunken switches they make. But after this, I don't think I will be getting any more of them any time soon.

Let's start by introducing our culprit. It's the Kailh CPG123201D01 switch. It belongs to the family of so-called "chocolate" switches — mechanical keyboard switches that have short key travel and a low profile. They also differ from regular "box" switches with price — they are almost twice more expensive. But if you want your keyboard to be thin, it's the best you can get. Those particular ones allow you to make it even thinner by making the switch "sunken" — part of the mechanism actually goes into a hole in the PCB, making the whole assembly a millimetre or two thinner still. Of course it makes the PCB design a bit more complicated, as you have to include all those holes, and then route tracks around them, but I decided it was worth the effort.

One interesting thing about all those "choc" switches is that the clicking mechanism (or tactile feedback, for the non-clicky ones) is separate from the contact mechanism. This animated GIF shows this nicely (it's for a non-sunken version):

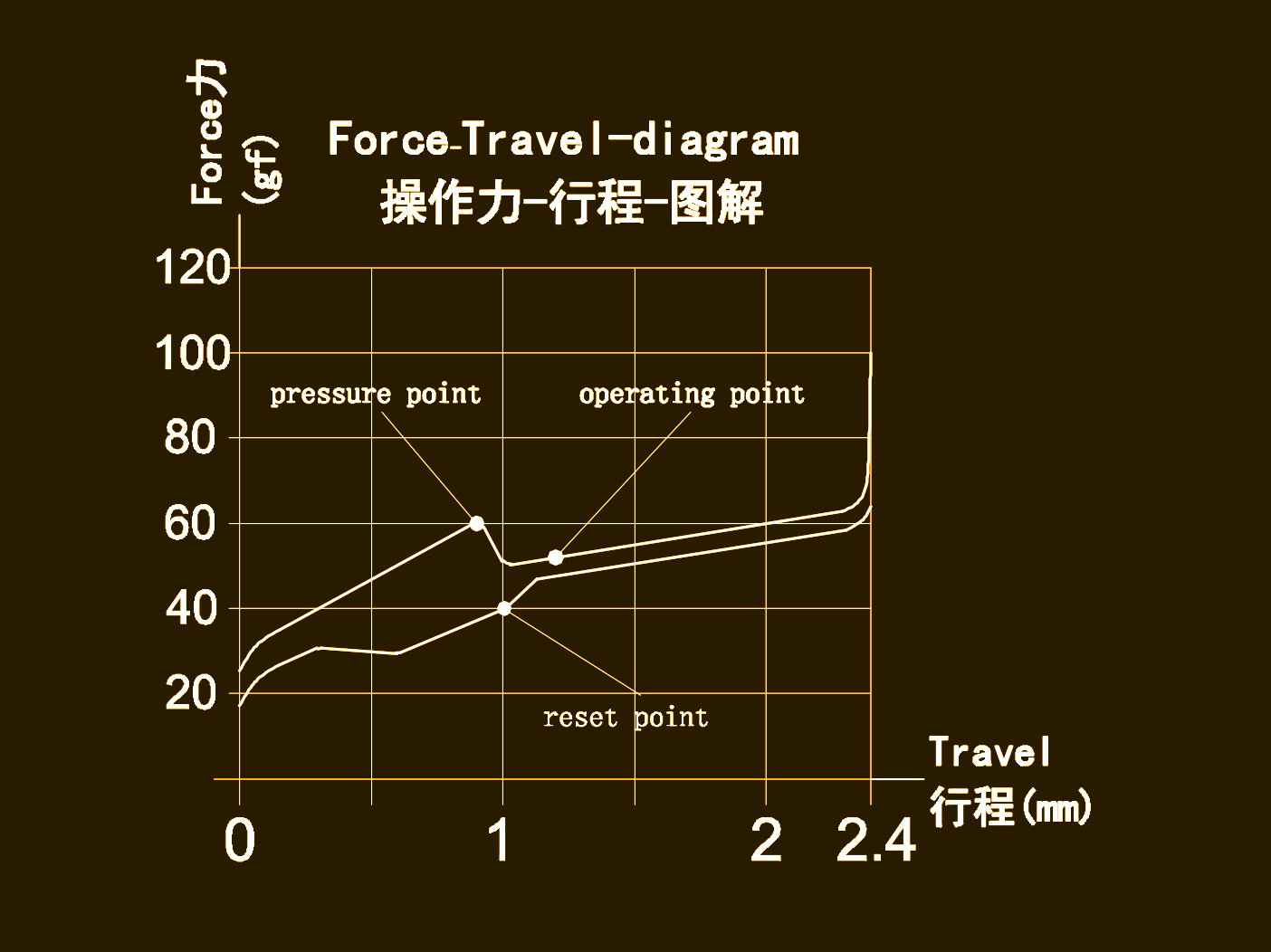

The spring on the left (called "click bar") is responsible for the clicking, but the actual contacts are on the right. Now, if you look at the datasheet linked from the manufacturer's page, you will find, among the footprints and dimensions, this handy graph representing the force required to press the button versus the travel of the key:

You can also see three points marked on that graph: the "pressure point" is when the click happens, the "operating point" is supposed to be where the contact happens, and "reset point" is where the contact stops. In theory, at least.

The switches I have work quite differently to what this graph shows. They click when you press the key less than one millimetre — so far so good — but then the contact doesn't happen until they bottom out completely — that is, until the reach the maximum travel of 2.4mm.

Sufficient to say that this makes the switches seem extremely unreliable. You are typing happily, hearing the satisfying clicks, only to discover that most of the keystrokes didn't register at all. You have to push the key all the way down to make it do anything. It's extremely annoying.

I don't know if this is just a faulty batch, or if it's something I did with them that made them work this way. Or maybe there is some way to fix them (if you know any, please leave a comment). All I know that as it is this keyboard, and any other I might ever make with those switches, it's completely unusable.

deʃhipu

deʃhipu

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.