Introduction

After building and testing the machine, I started to notice some limitations, small design issues, and areas where improvements could be made. Several iterations later, I have an updated design that smooths out these rough edges.

Many of these are significant and will get their own log entries like a completely new head design, PCB holder, custom light, and nozzle tip holders. Stay tuned in for those.

Below are a few additional updates.

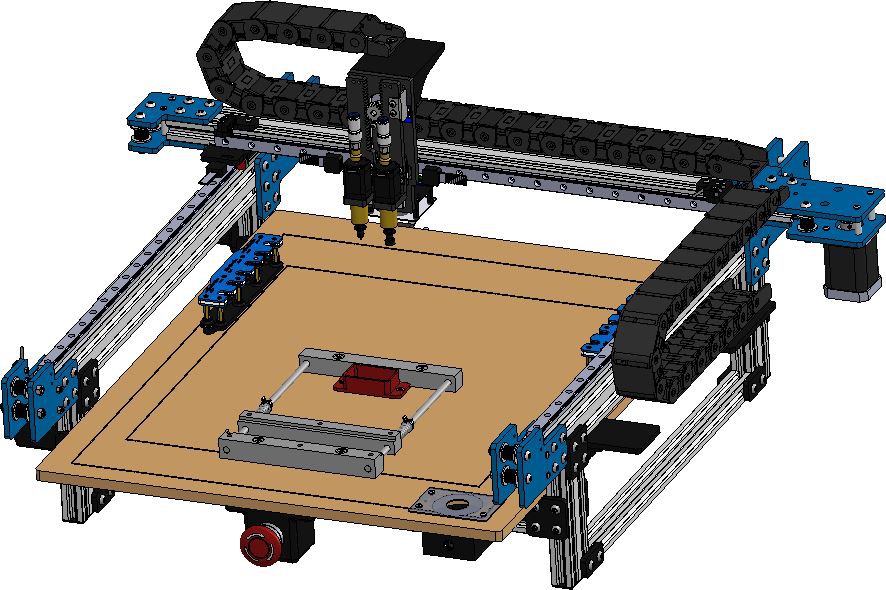

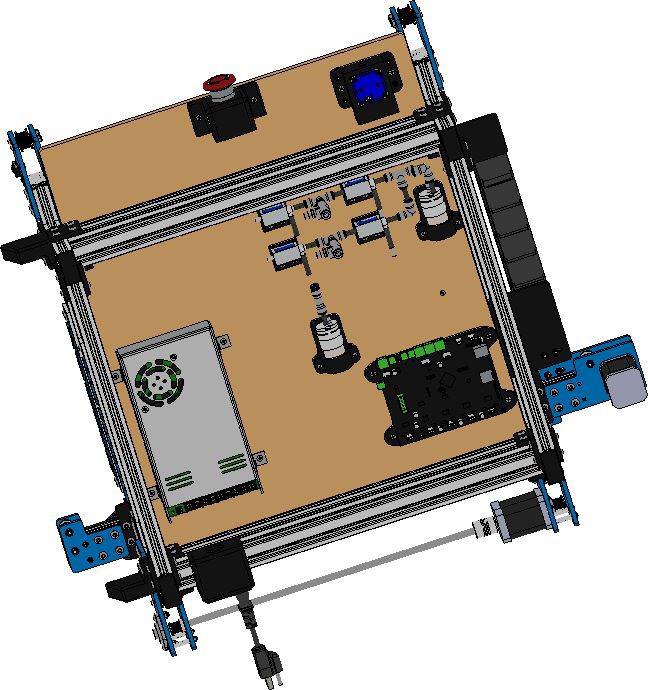

Here are some updated images of the machine.

Removed the LCD Screen

After testing with the LCD screen, it was determined it added little value to a pick-and-place machine. Unlike a 3D printer, a pick-and-place is always connected to a computer. All of the information that the LCD screen would be used for is available on the computer and easier to access. The emergency stop button was integrated into the original LCD screen mount, therefore, a new stop button holder was designed.

Camera Changes

The bottom camera was horribly mounted in the middle of nowhere. The consequences of this became apparent almost immediately. A shorter focal length was chosen to both allow the camera to be closer to the build table while maintaining the field of view, This also allowed the same cameras to be used for both the top and bottom.

Lance

Lance

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.