Introduction

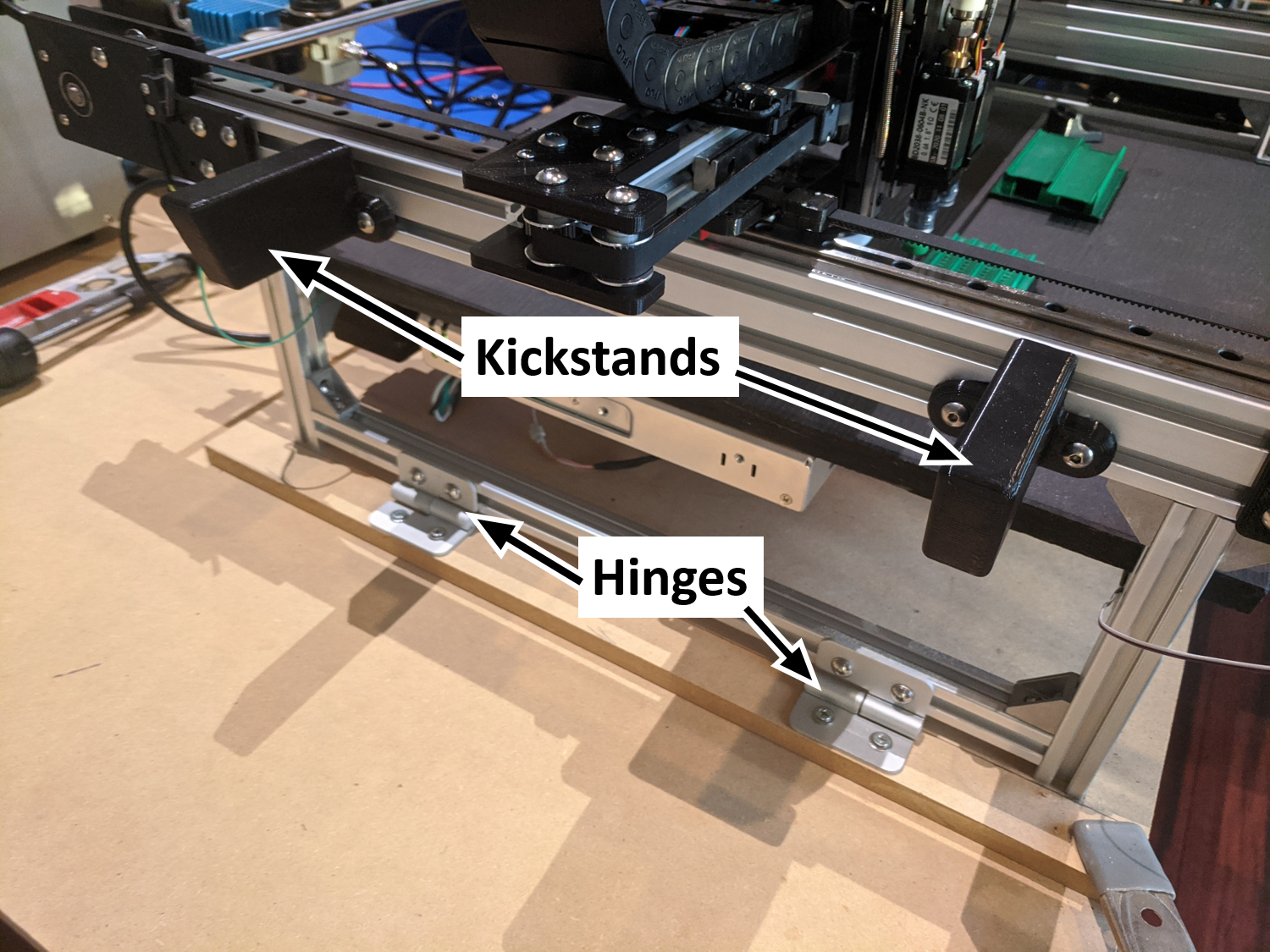

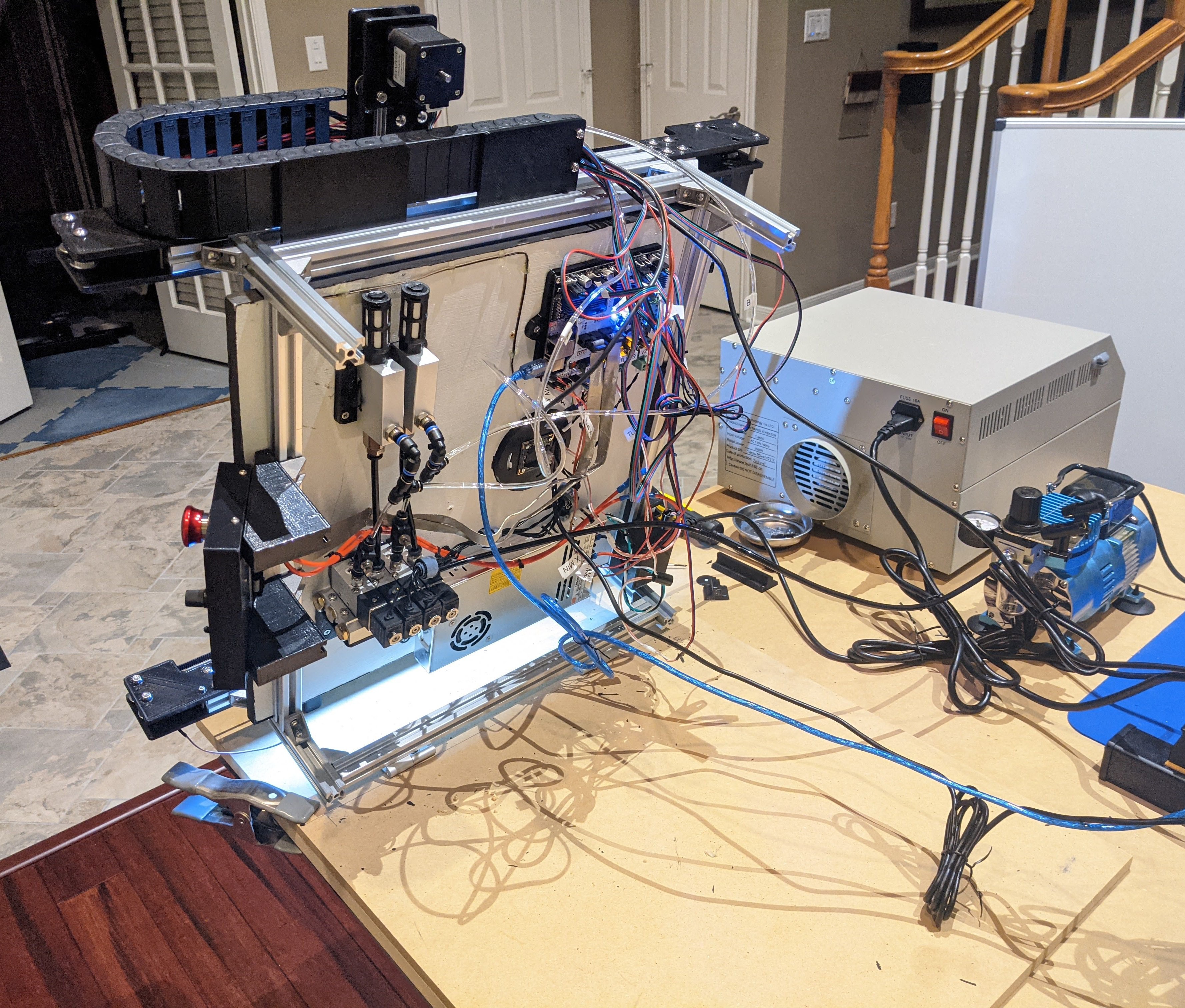

As with all first builds of a design, there was one thing that was certain: Changes were going to be required. And likely, they were going to be frequent. That's part of the process. Debugging and testing were going to create an even greater need to access the electronics and mechanics in the base of the machine. And that was going to be a problem. Unscrewing the build plate or disassembling part of the machine wasn't going to an option. This would require too much work and risk messing up machine alignment or setup. The solution was to put the machine on hinges so it could be flipped up.

Setup

On one side of the machine, a set of hinges connects the machine to a base plate. A set of 3D printed kickstands attached to the side provide a place for the machine to rest on.

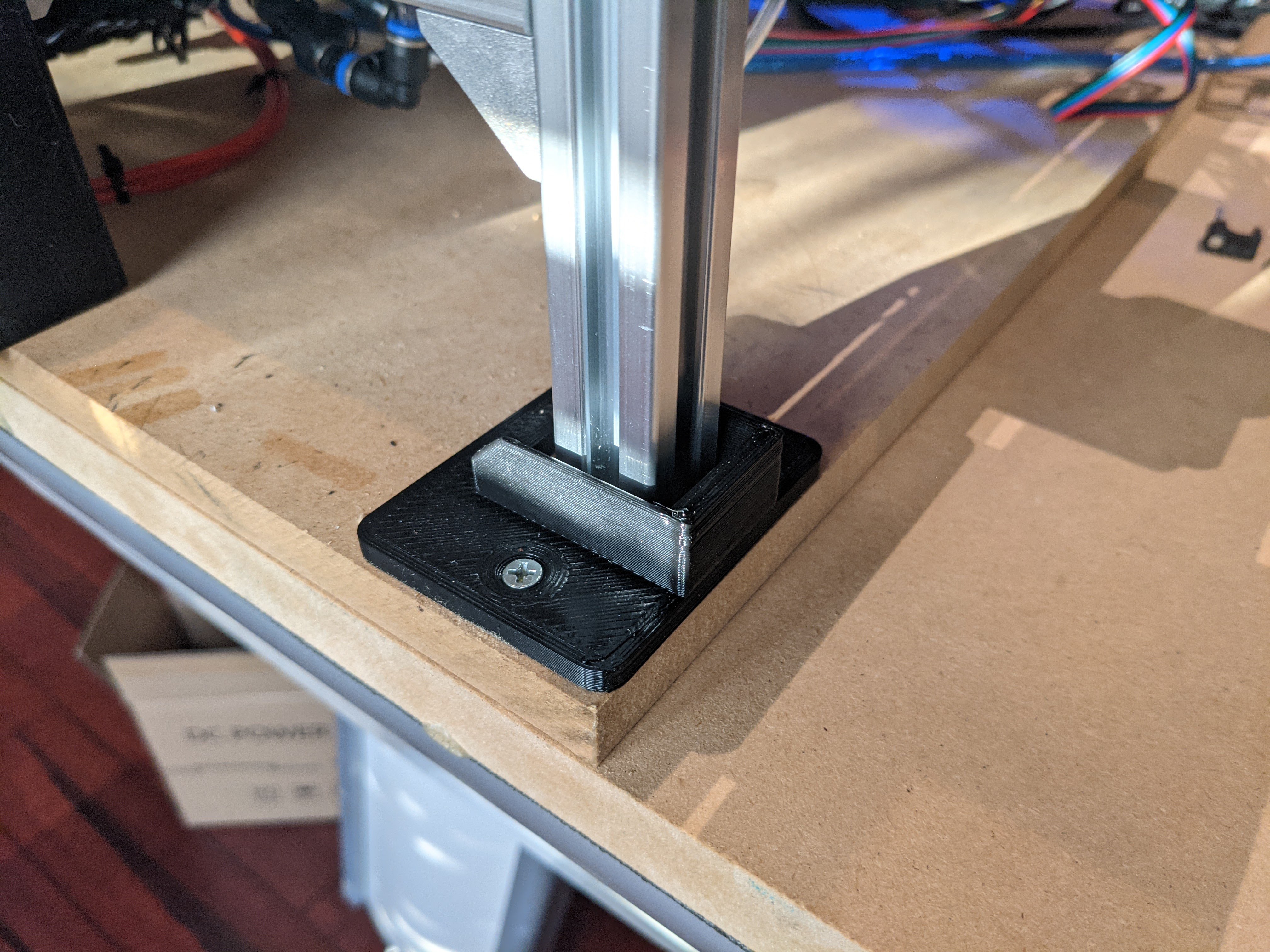

On the opposite side, there are some 3D printed brackets screwed to the mounting plate. These are not attached to the machine. They act to ensure the machine is repositioned in the same place each time it is tipped up and set back down.

Lance

Lance

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.