I was finally able to finalize the backpanel to enclose the electronics at the back. In the meantime I've worked on the tools as well and ordered some directdrive extruders as well as a new hotend for higher temps.

Forex for lightweight backpanel:

A good friend of mine recommended the use of forex for the backpanel as alternative to the classic pmma-panels. At first sight I was quite hesitating but I'm glad that I tried the forex panel. Forex panels are rigid foam sheets made out of pvc and therefore are slightly lighter as PMMA (acrylic) panels. The texture is a little more rough but shines slightly. I think it is a little more scratch resistant which is quite nice for a panel which comes off from time to time.

For better appearance I've quickly designed some grids/covers for the outlets and inlets.

For better appearance I've quickly designed some grids/covers for the outlets and inlets. Small directdrive tool:

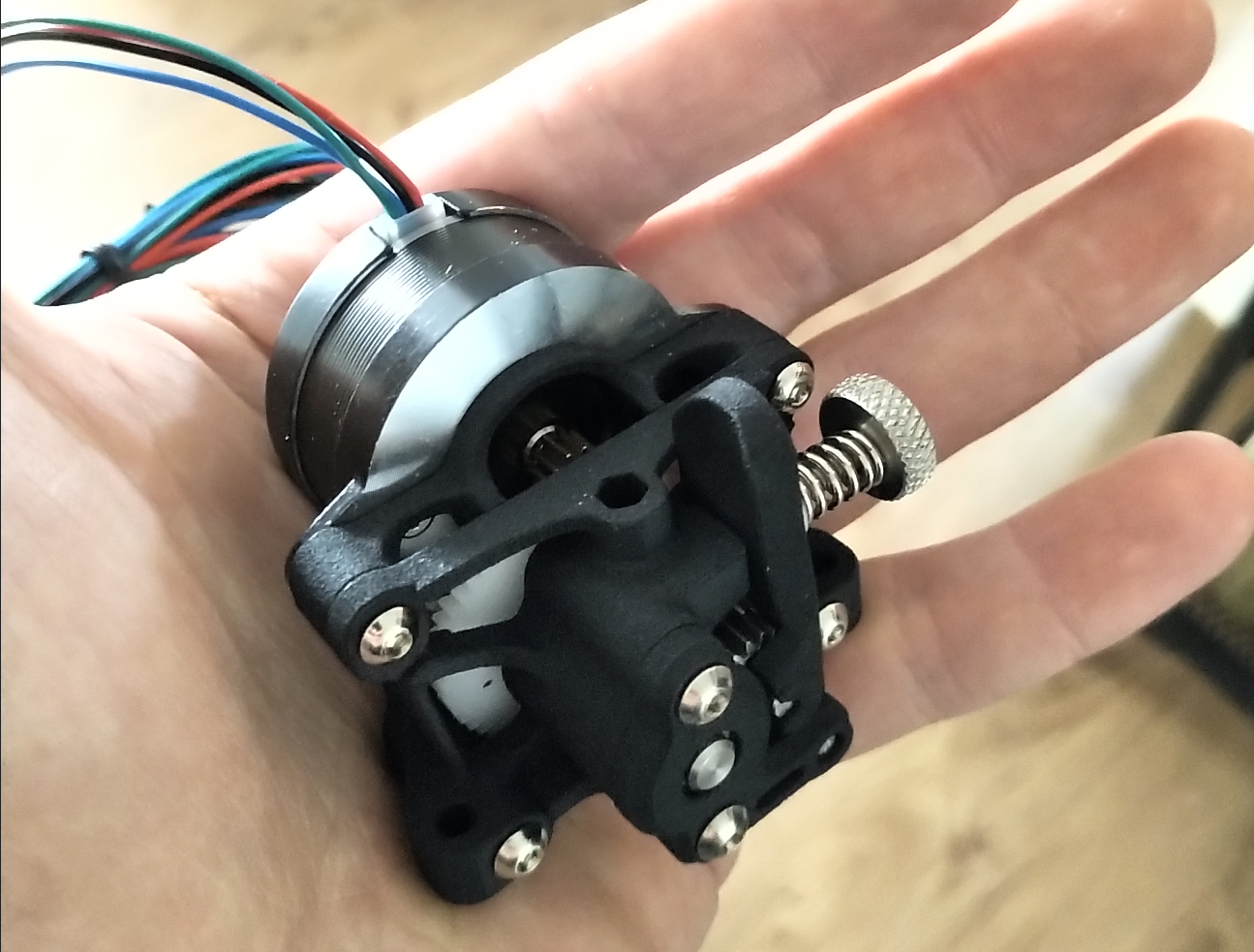

I've wanted to test the sherpa mini extruder for quite some time and finally ordered the sls version (https://de.aliexpress.com/item/1005002494710230.html?spm=a2g0o.productlist.0.0.30ec7130oG9BBu&algo_pvid=87f7ac3f-df22-4230-a4ae-85986f715eec&algo_exp_id=87f7ac3f-df22-4230-a4ae-85986f715eec-11) Just one out of many possible sellers!

The quality seems fine and the form factor is quite nice for the limited space of the CHANGER-Tools.

For the hotend of the first directdrive tools I wanted to use the DyzEND-X Hotend (DyzEnd-X Hotend 1.75mm - Fast Printing - DYZE DESIGN)

I'll need to finalize the actual tool and print the first holder to test the directdrive hotend on the CHANGER. I'll post the first results as soon as I'm able to continue the work on my printer.

Simon Wirz

Simon Wirz

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.