I'm currently trying to get a proper cover done to fully enclose the printer. My main goal is a universal topcover with full accessibility to all relevant functions of the printer (tool-change, belt tensioning, watercooling outlet, air-outlet etc.) without loosing the industrial look of the printer. My least favorite option will be a acrylic-extrusions assembly.

My current designs:

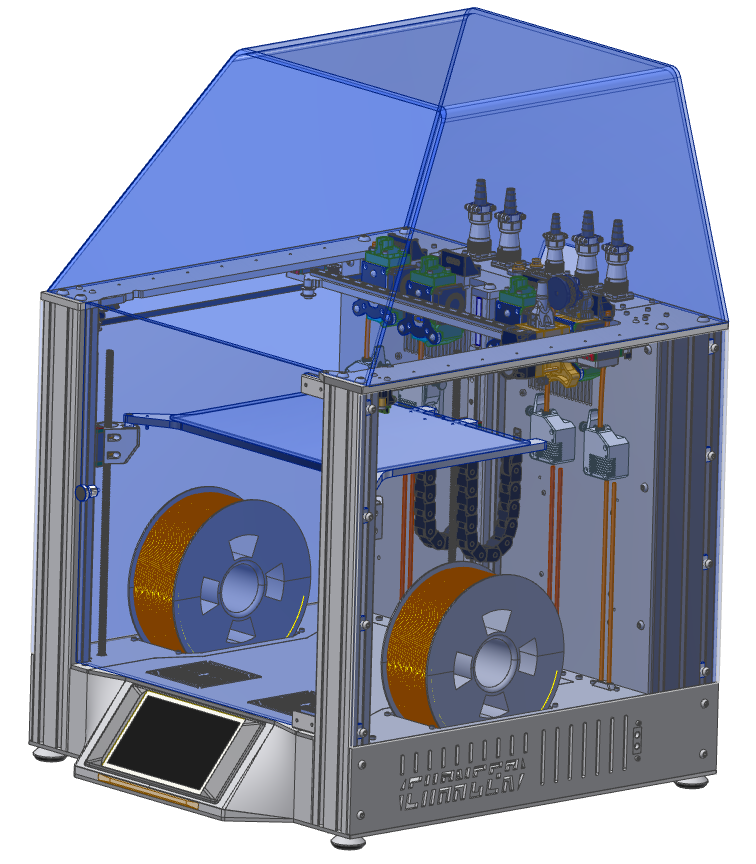

Design 1: Bent-acrylic (illustration, not finished):

This design is minimalistic but functional. The backside consists of the backpanel and a latch/hinge so you can easily access the tools (not implemented in the design yet). The same principle could be applied to the front panel as well but it would work with glued/screwed and therefore fixed front panel as well.

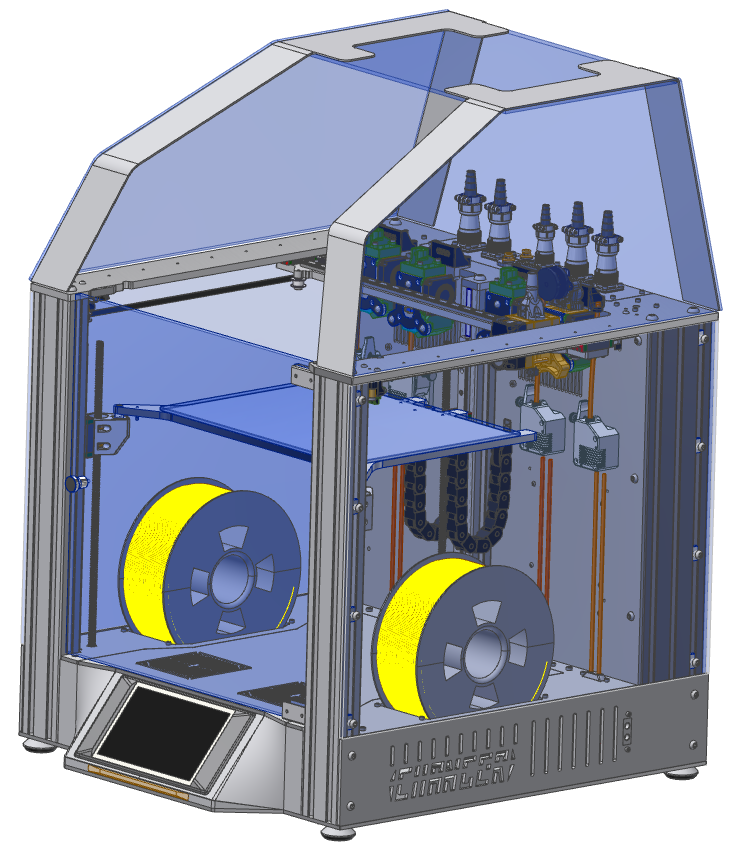

Design 2: Aluminium-construction (illustration, not finished):

This design is more complex but still fully functional. The mainframe consists of two bent aluminium sheets which gives this assembly the rigidity. The flat top panel/sheet is fix mounted on to the mainframe/two aluminium sheets. The back and the front will get hinges as well so you're able to access the toolhead from the front and the tools/tooldocks at the back by open up the panels. You could even get rid of the first bend and bend it more like in the first design so you can simplify the bending geometry of the two aluminium sheets.

C.A.D of Design 2 (Cardboard Aided Design ;) )

Your opinion? / Conclusion

I'm still kinda undecided about the direction of the top cover. The top cover is key to the overall appearance of the printer and I want the printer to look quite industrial and therefore I'm struggling with some quick&dirty covers. I even bult a cardboard cover of the 2nd design to see if the design ''grows'' over time. What's your opinion about the design direction of the top cover for such a motion system / toolchanger? Let me know your thoughts in the comment section.

Simon Wirz

Simon Wirz

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.