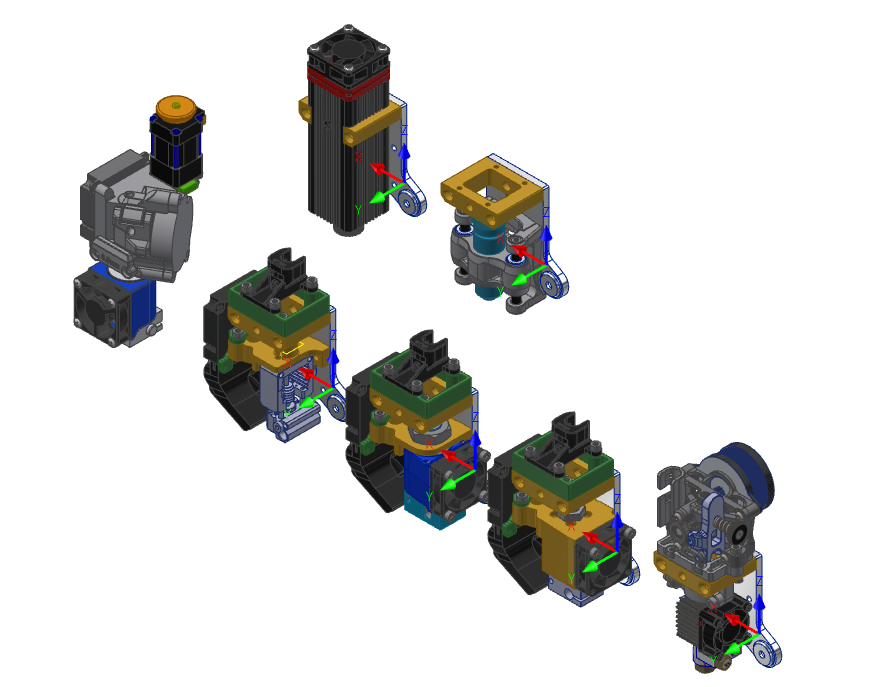

Because my main-goal is to create a large variety of tools for my CHANGER I've created an assembly file with all designed tools. In Addition I've measured the toolplate offset relative to the endstop (z-Endstop). The centerpoint of the toolplate is then added as a individual coordinate system which allows to quickly output the offset of new tools. In order to get the offset of a tool you just measure center of the nozzle, spindle etc. relative to the coordinate system and you'll get the values for Duet.

Current Tool's:

Simon Wirz

Simon Wirz

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.