In my first Benchy-attempt I noticed the heavy cooling issues with my mosquito-Bowden tool. Despite that the printer performed as expected. Before I build more tools I want to adress the cooling issues with the first tool so I can implement the cooling Design (Fan powered) in my next tools. I haven't tested the integrated airpump because I don't want to use it for my PLA-Bowdentools.

Comparison (Datasheet):

| Fan-Type [-] | Source [-] | Airflow [m³/min] | Weight [gr] |

| Delta, BFB0412HHA | https://www.infinity-element.com/product/Delta-Electronics_ BFB0412HHA-A.aspx | 0.084 | 12 |

| NMB, BM4515-04W-B50-L00 | https://www.digikey.ch/product-detail/de/nmb-technologies-corporation/BM4515-04W-B50-L00/P15680-ND/1633698 | 0.098 | 20 |

| Delta, BFB04512HHA | https://www.infinity-element.com/product/Delta-Electronics_BFB04512HHA-A.aspx | 0.090 | 13 |

| Micronel, D243L-006KH-5 | https://www.distrelec.ch/en/axial-fan-dc-28x28x30mm-6v-4m-micronel-d243l-006kh/p/30068220 | 0.090 | 17 + 15 |

If you compare the Airflow to Weight ratio the best options are:

- Delta BFB04512 (45x45x12mm) with 0.0075 [m³/min] /gr

- Delta, BFB0412 (40x40x10mm fan) with 0.007 [m³/min] /gr

- NMB, 4515 (45x45x15mm Turbofan) with 0.005 [m³/min] /gr

- Micronel, D243 (impeller-Design) with 0.002 [m³/min] /gr

Decision for first Bowden-Setup:

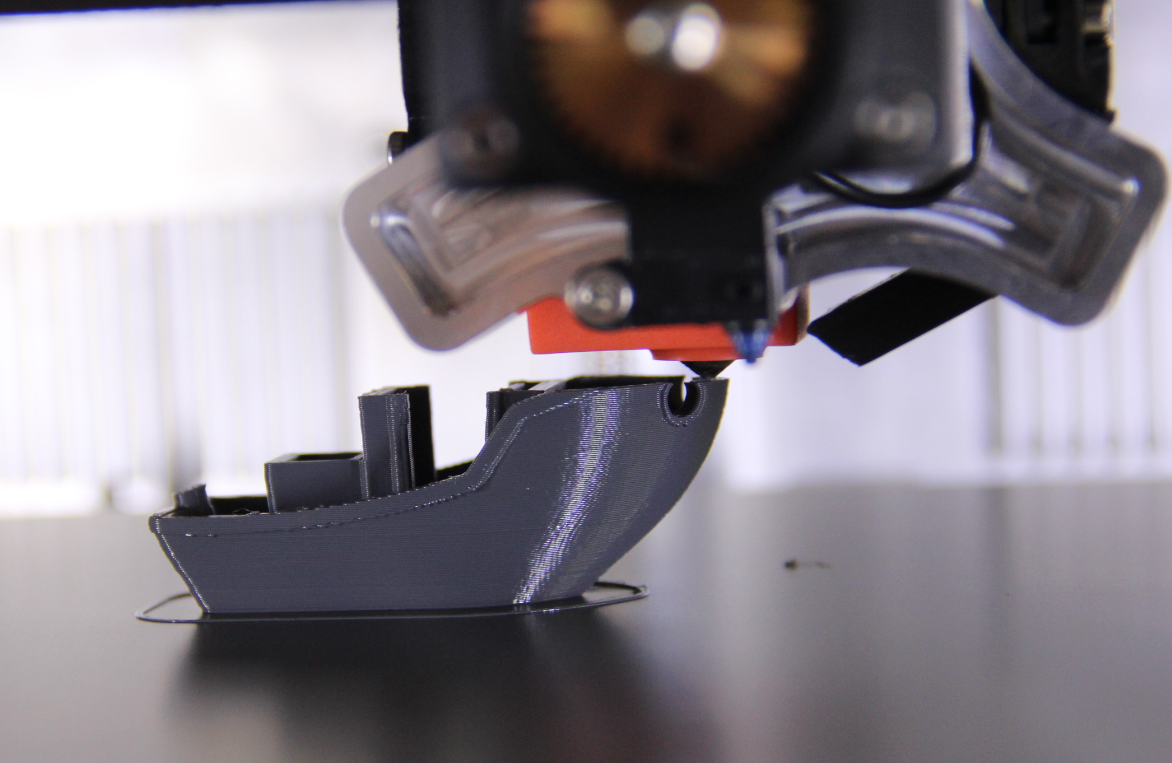

I've redesigned the Bowden-tool and used a Trianglelabs Dragon-Hotend and sticked to the 40x40x10mm fan because of the good airflow to weight ratio and re-oriented the benchy on the buld plate so the fan blows to the overhang section at the front.

With the new setup I was able to print a proper benchy. For now I'm quite happy with the result and I will start testing with some genuine GT2 belts and start machining the currently 3d-printed belt tensioner so it can withstand higher tension forces.

Simon Wirz

Simon Wirz

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.