Altough I'm not fully satisfied with the current top design I'll start buidling the 2nd Prototype which I've showed in the last log. The hole top cover will be printed with a normal FDM-printer with a built plate area of an A4 (210x297mm) and therefore it's little bit tricky to cut this large part in different pieces.

The different sections:

The top cover is split up in two main halfs. The half section is split up again in six different segments. The parts are mounted and secured with rods and bolt-on segments.

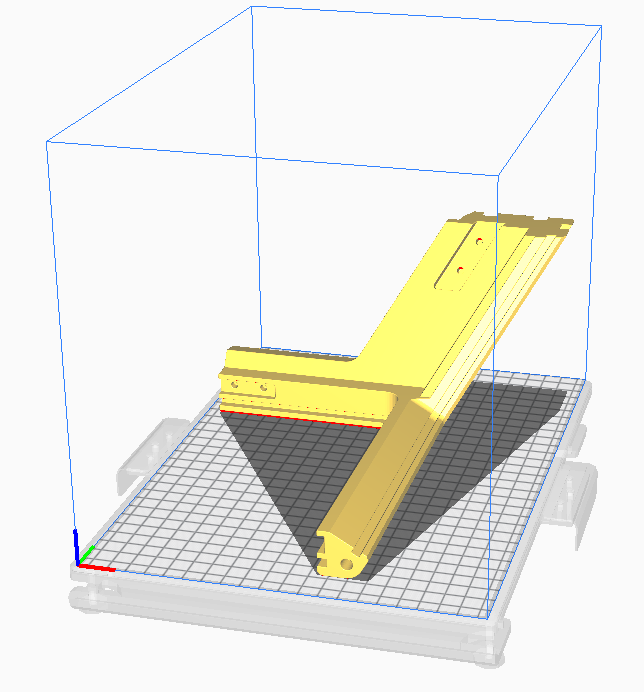

Max-out the build volume of my 3d printer

The parts fit quite tight inside the mentioned build volume of 210x297x200 (lxbxh) but It should work for a first top cover.

The parts fit quite tight inside the mentioned build volume of 210x297x200 (lxbxh) but It should work for a first top cover.I've tried to design the parts in a way that the need of support structures is a low as possible to save filament and reduce print time. The latter should be around 120h of print time which is enormous compared to my usual 3-8h prints.

Building/Printing the first parts

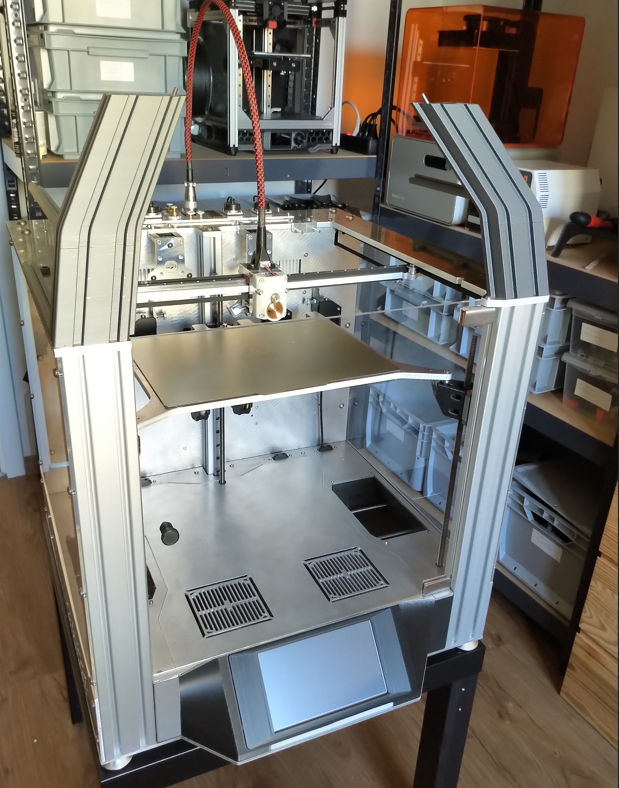

The first four parts of the topcover are printed and mounted on the printer. So far so good and maybe the design grows on me over time so I don't have to design a completely new one

Simon Wirz

Simon Wirz

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.