Now with the whole build almost complete I want to solidify the motion system with more metal parts

Initially I've used PLA-parts. After some time I've designed a second version of the tensioners to be printed in my SLA machine but wasn't satisfied either.

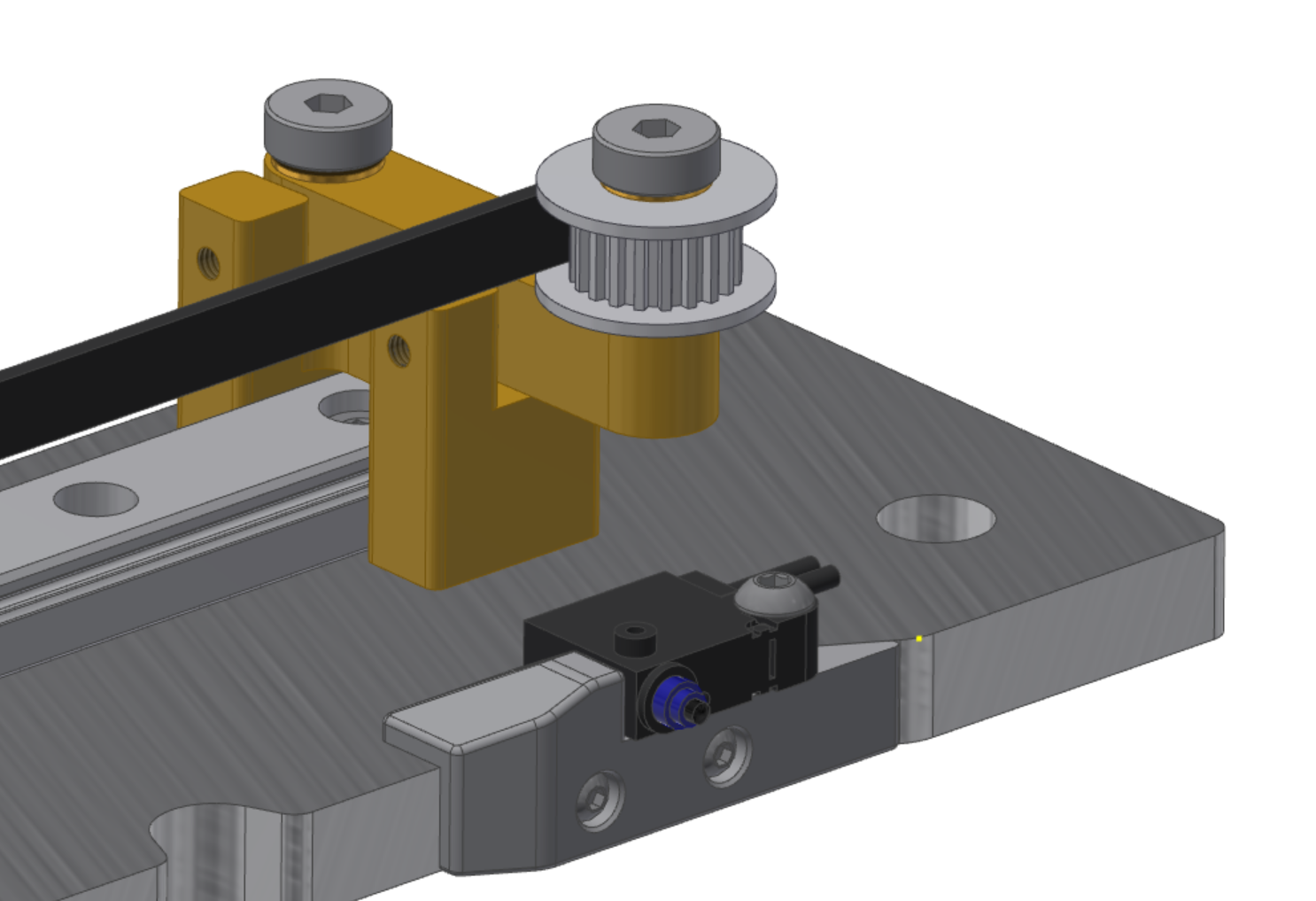

Tensioner right (with endstop)

I've used the tensioner from E3D as a reference and rebuilt all the parts to fit into the CHANGER. Because I don't like sensorless homing I've added a microswitch for the Y-Axis. That's actually the reason why I've stayed with PLA-parts for so long because I've integrated the microswith directly into the old tensioner design. Yesterday I've had the idea to use a spring on one side to not loose the tensioning feature. Now you're able to tension the belt ''trough'' the microswitch mounting hole without loosing the reference.

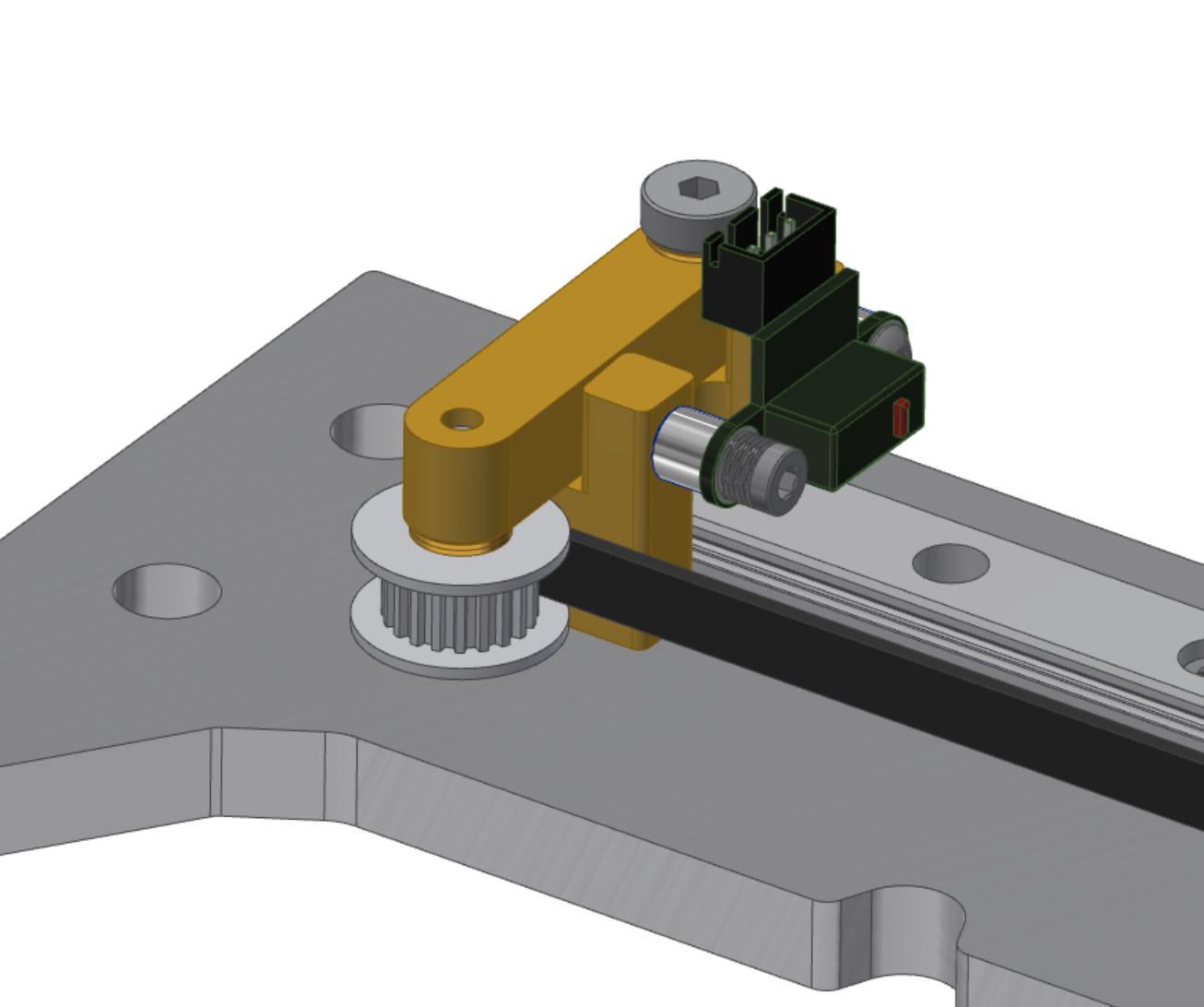

Tensioner left

On the other side the tensioner is identical but without the need of a microswitch for the Y-Axis.

In the next days / weeks I'll wait for the machined parts and I will start testing on actual printing / laser engraving and cutting.

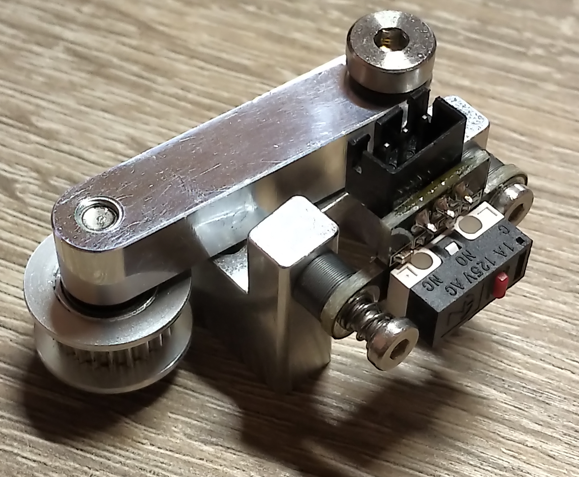

Update: 13.07.2022, milled parts:

Simon Wirz

Simon Wirz

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.