Previous Issues Addressed

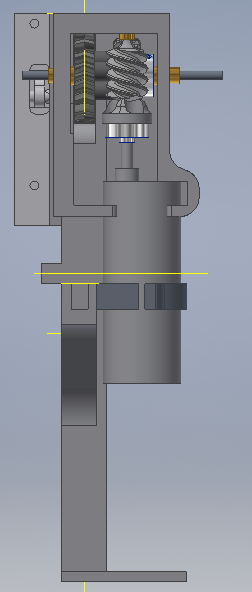

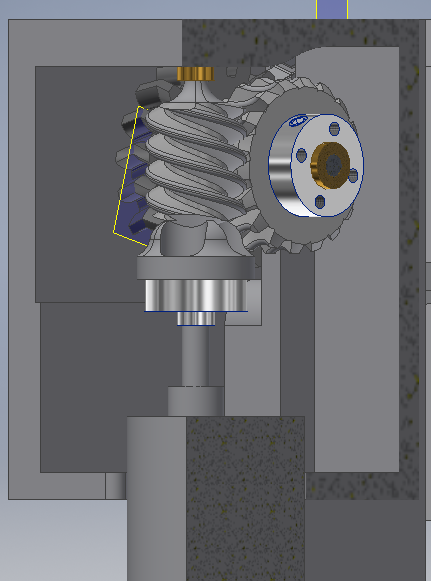

Both issues (not strong enough and the weak motor-mount support) were addressed with the redesign of the upper rack housing. The new design geared down the motor to increase the torque, by using worm gears. I'd never used worm gears, but they are known for being compact in terms of space used versus the gear ratio. The new gear type moved the motor parallel to the rack housing, meaning the force acting on the housing during lifting/lowering could be better distributed.

Issues

The worm-gear system proved to be a major flop; the 3d-printed worm gear broke at its point of attachment (i.e. between the base and the point of attachment). Perhaps gears made of metal or a strong plastic such as nylon would have worked.

Silas Waxter

Silas Waxter

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.