As Spring Break begins, we have again several consistent days where we can come everyday to the lab. Yesterday and today are two quite busy ones, as we worked on several different aspects of this project, the 3D model parts, opto-mechanical parts, and also parts that needs to be laser cutted and fitted together for the optical areas of the microplate reader. We also designed and 3D printed several appropriate models used to place the switches along the X and Y axis, these are used to make the plate holder stop when it hits the extremes of the axes.

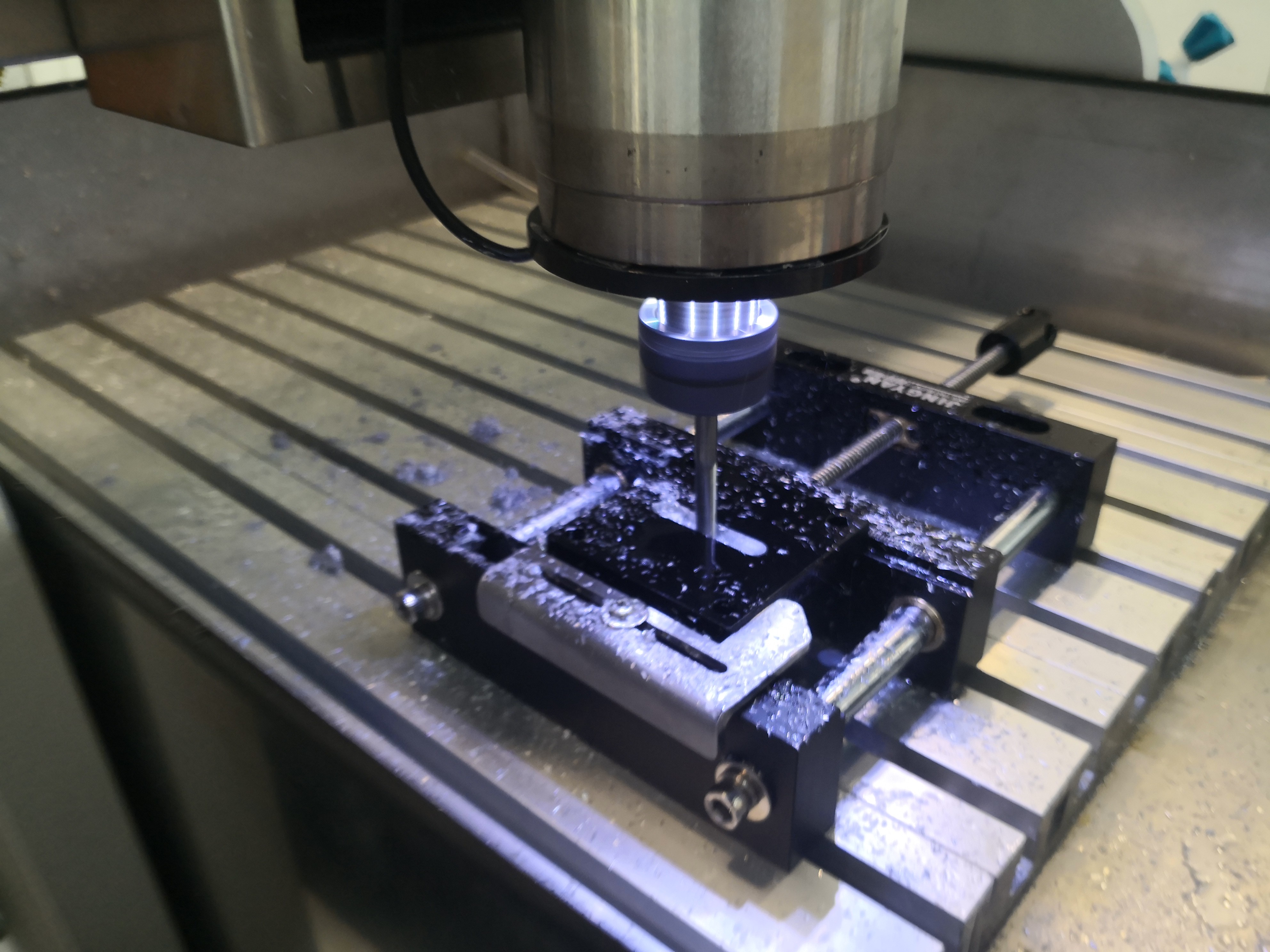

Adding on, we also used CNC to drill holes that are missing in the kits we purchased for the opto-mechanical parts.

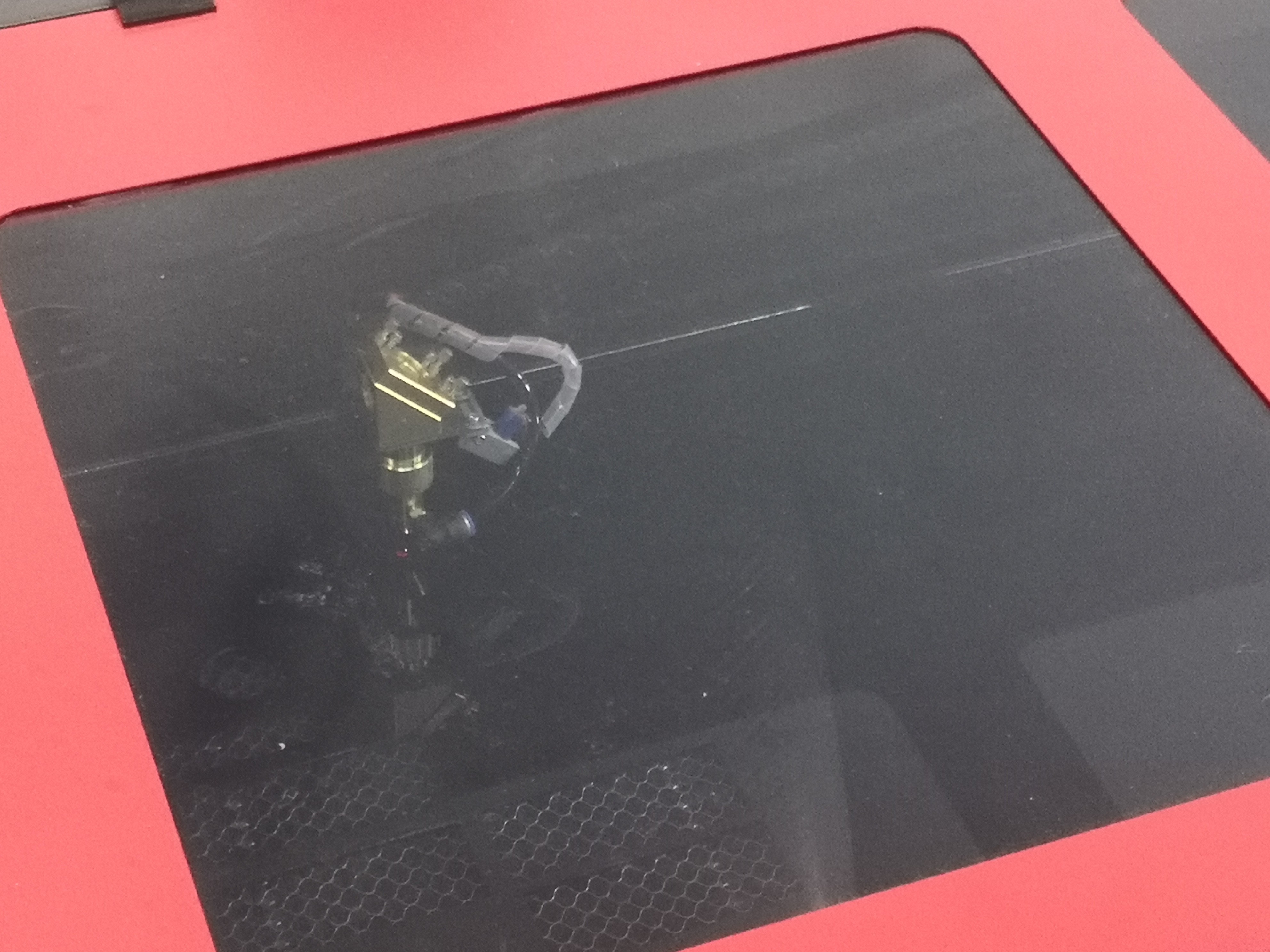

Last but not least, we also worked drawing a few figures on Inkscape in order to laser cut them and fit all the optical components together. We kept redesigning these components since we had to constantly test out new ones, to see whether they worked better than the failed prototypes we designed earlier.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.