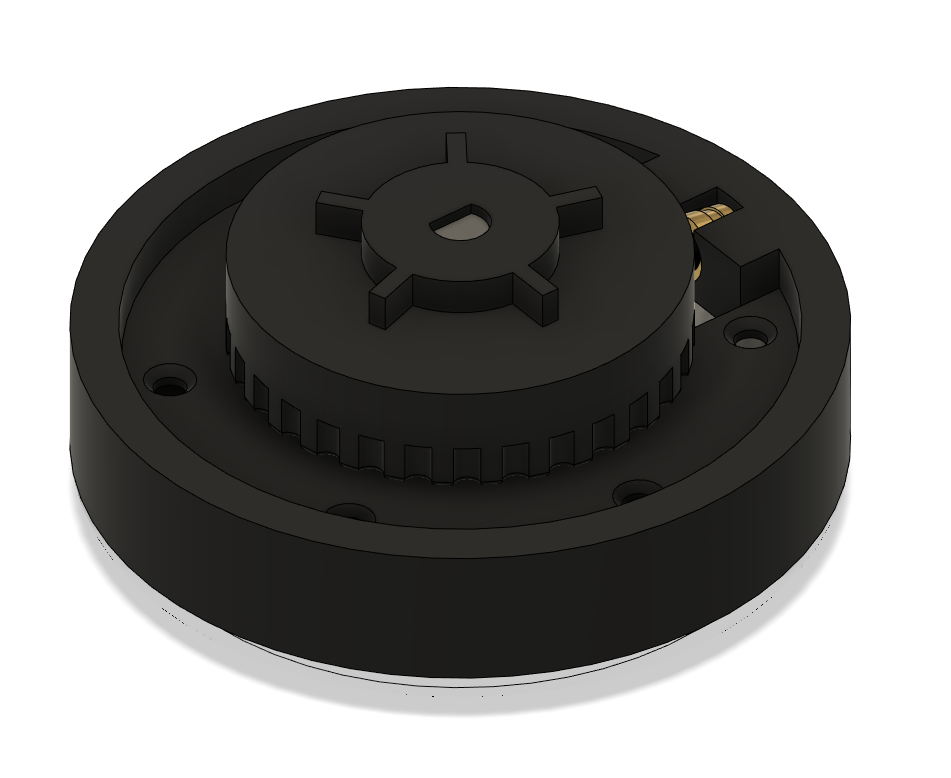

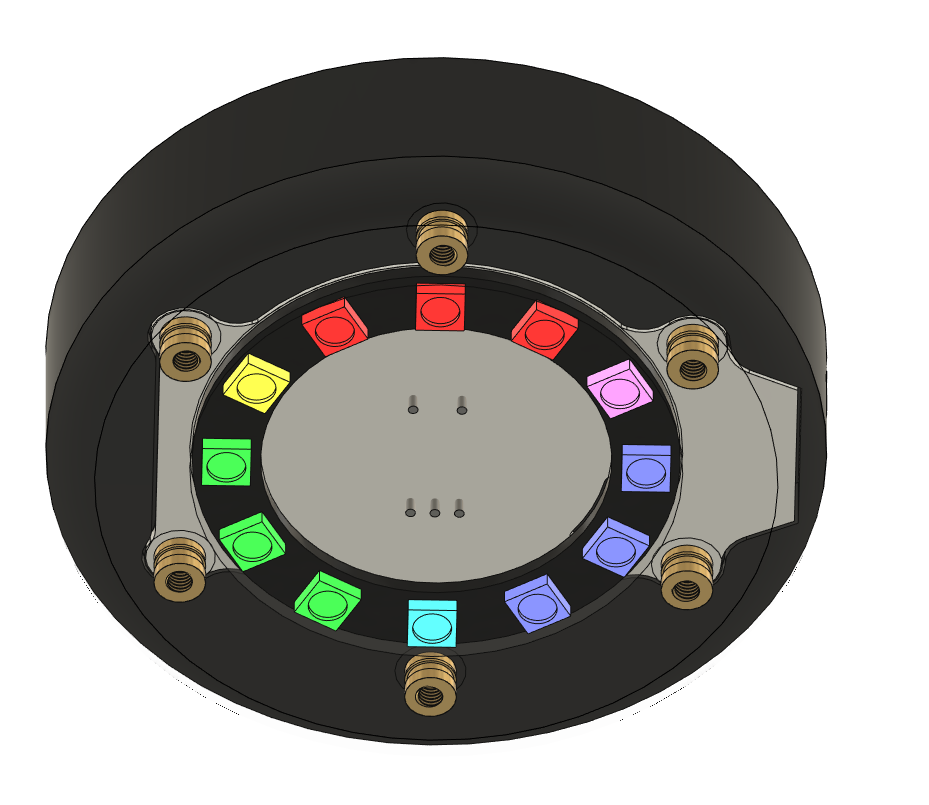

I have managed to think of a way to add better indents to the turning action. The PCB is in progress but the housing is nearly complete, currently printing the parts out for their first test.

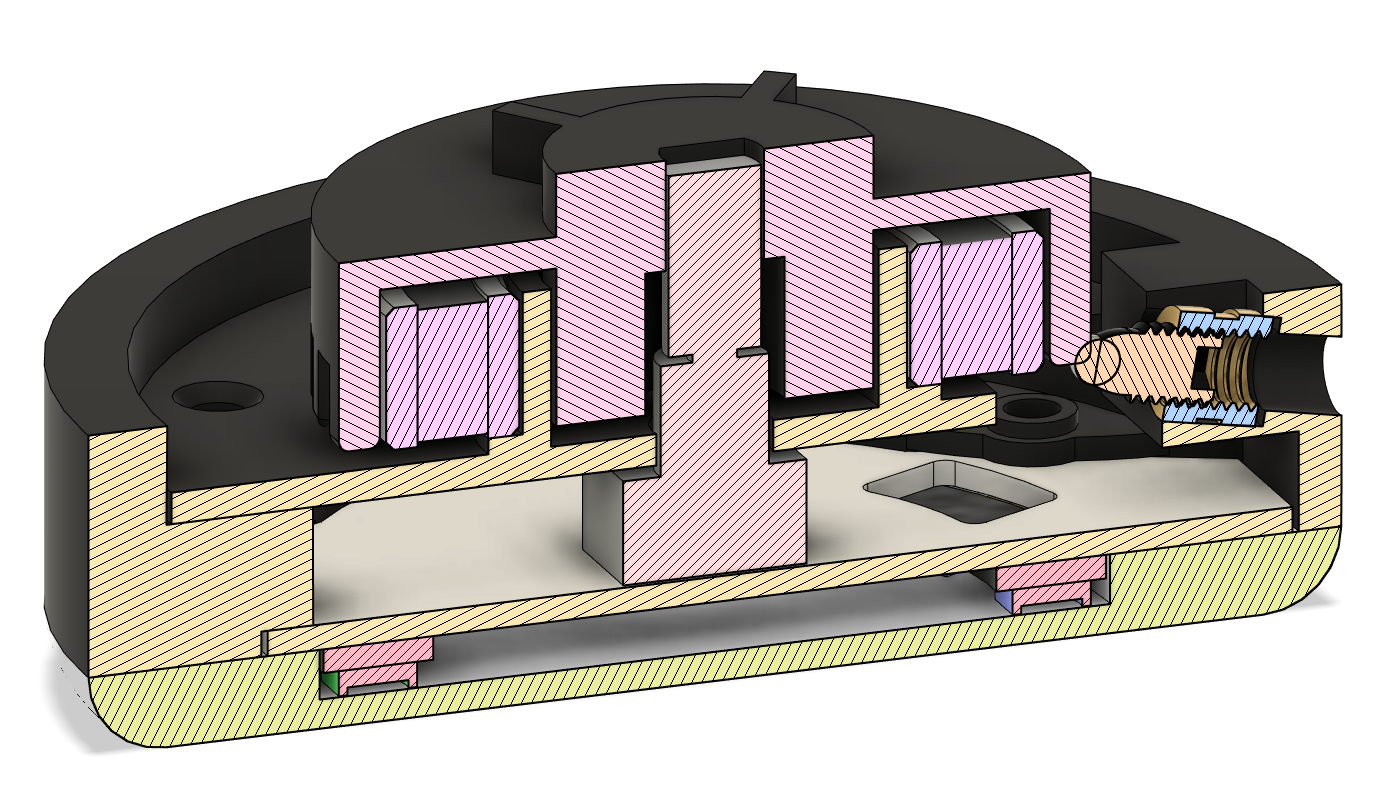

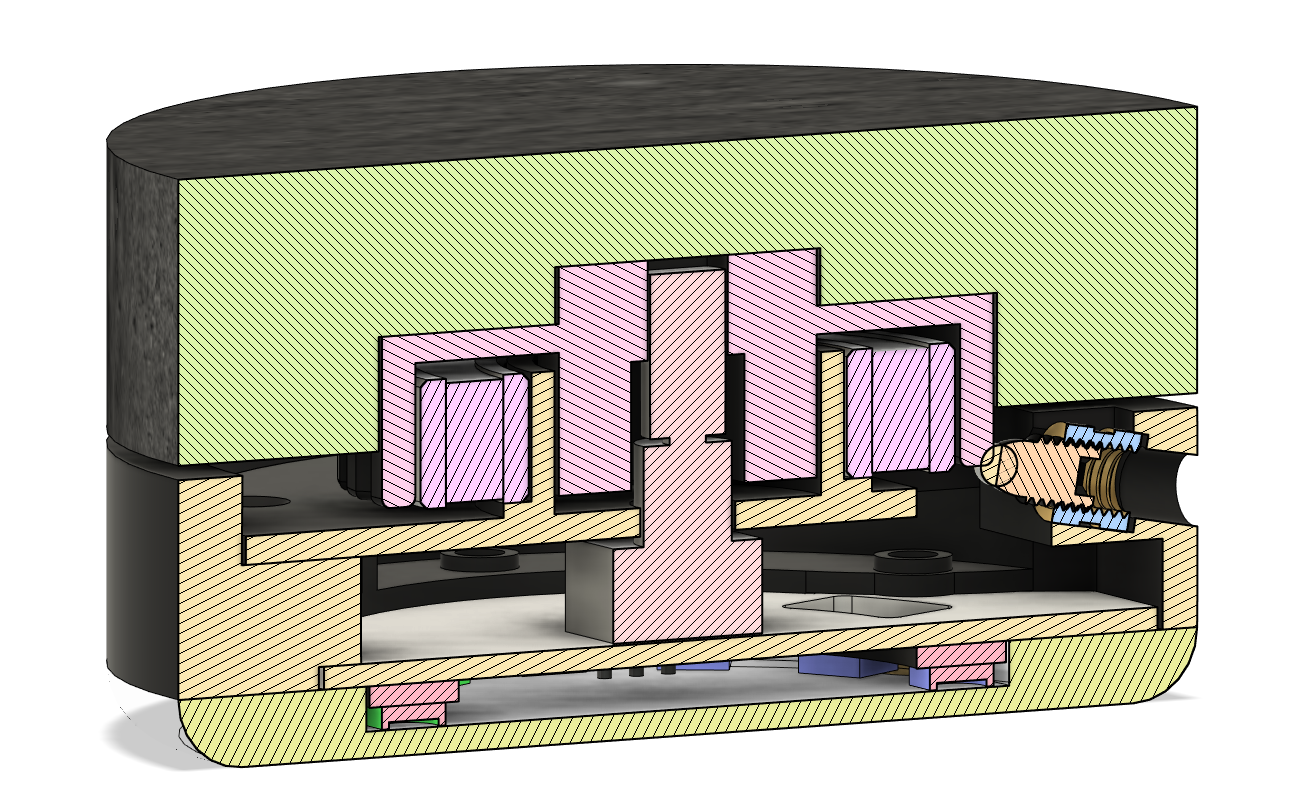

Major changes include:

- Large bearing to help prevent the knob from tilting and to make the turning smoother

- More substantial indent feedback, the force is also adjustable, will not wear down like the built-in one in the encoder (it is weak also)

- Using threaded inserts

- Encoder attached to the PCB itself and the body cover giving two anchor points

You can also see an animation of how the indent mechanism works

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.