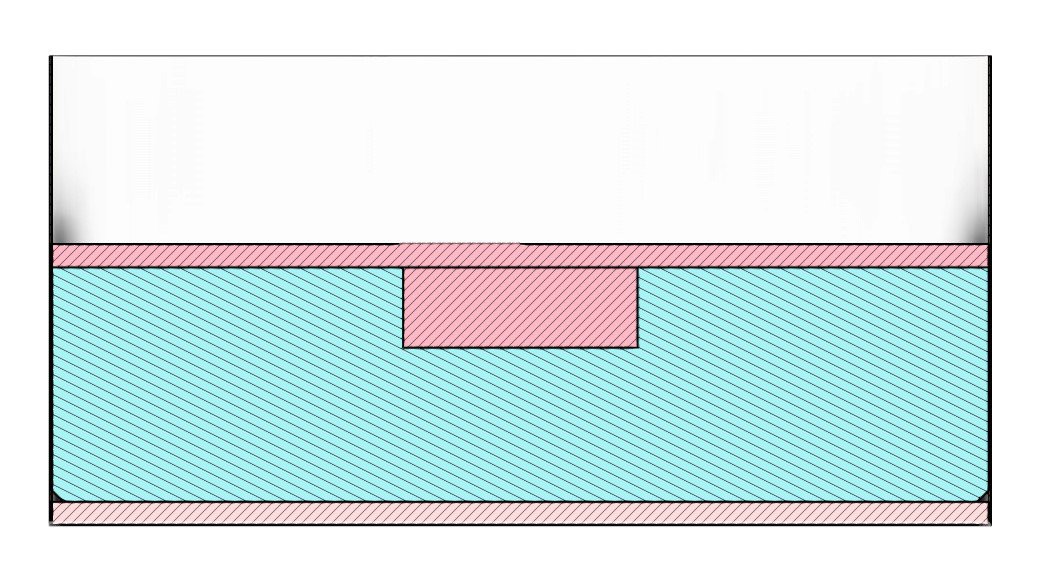

I am now planning my approach to mould the concrete into the knob shape. The mould consists of:

- A bottom disk

- Acetate sheet to form the wall of the mould

- A top disk with a blank piece shaped like the encoder coupler (the encoder coupler is to provide a better/replaceable connection between the knob and the encoder shaft because the only way to access the inside of the knob is to take the knob off first, so over time the concrete can wear, but with the coupler in place, I can just print a new one if it gets too loose).

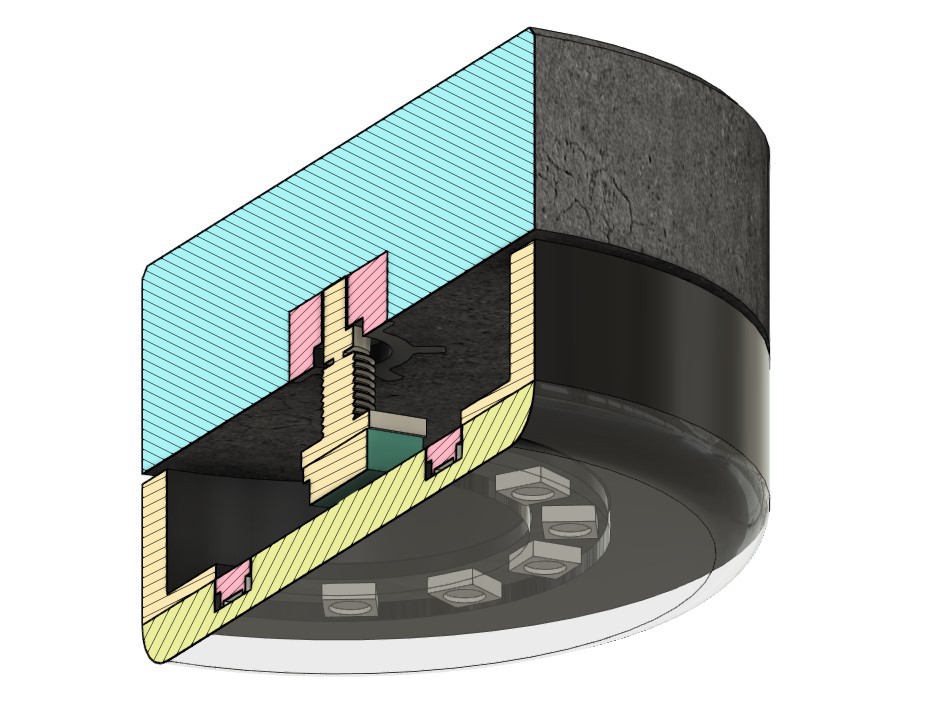

In these images I forgot to include another disk that the encoder will mount to in order to keep it centred, I have also found that clicking the encoder while it is on the disk and in the enclosure makes a louder and more satisfying sound.

I hope that the encoder's stepping will become more distinct with the concrete knob on as well as allow me to effortlessly flick/spin the knob due to the momentum of the knob.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.