What do we have?

0. A gaming laptop from Alienware with broken battery

1. Broken Alienware battery from that laptop

2. Working Alienware battery from a different laptop

Ain't no Alienware warranty on this laptop anymore, and being tethered to a wall socket at all times makes a laptop into a shitty desktop. Fixing the dead battery is likely a no-go - the controllers are black boxes, there's people that know the details about them but it costs money, and I'd need to re-cell the battery anyway - spot welding batteries in a live pack isn't my favourite pastime.

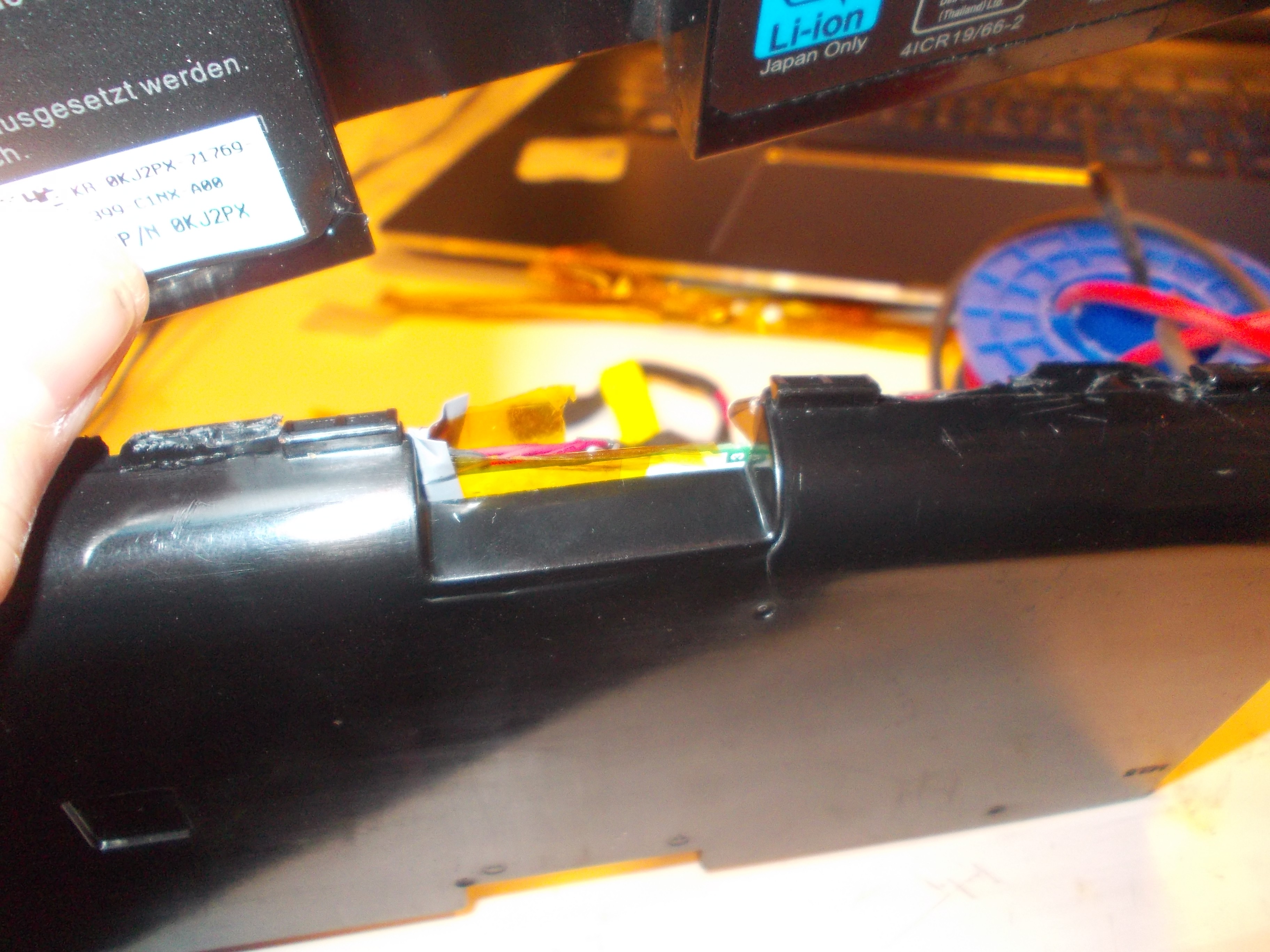

When plugging the 2. battery into the laptop, the laptop would work wonders. Internally, it looked really similar - same cell arrangement and very similar controller board.

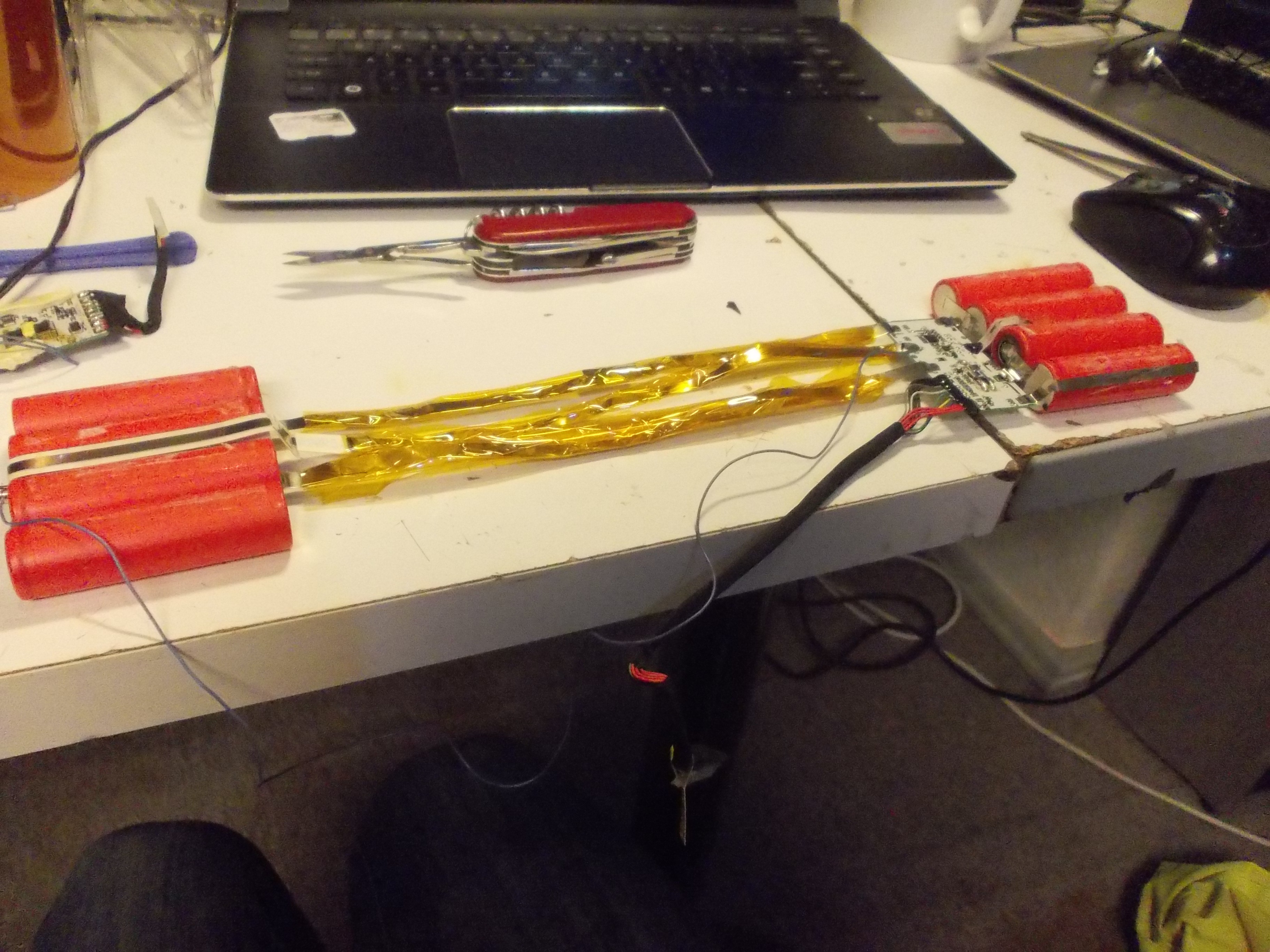

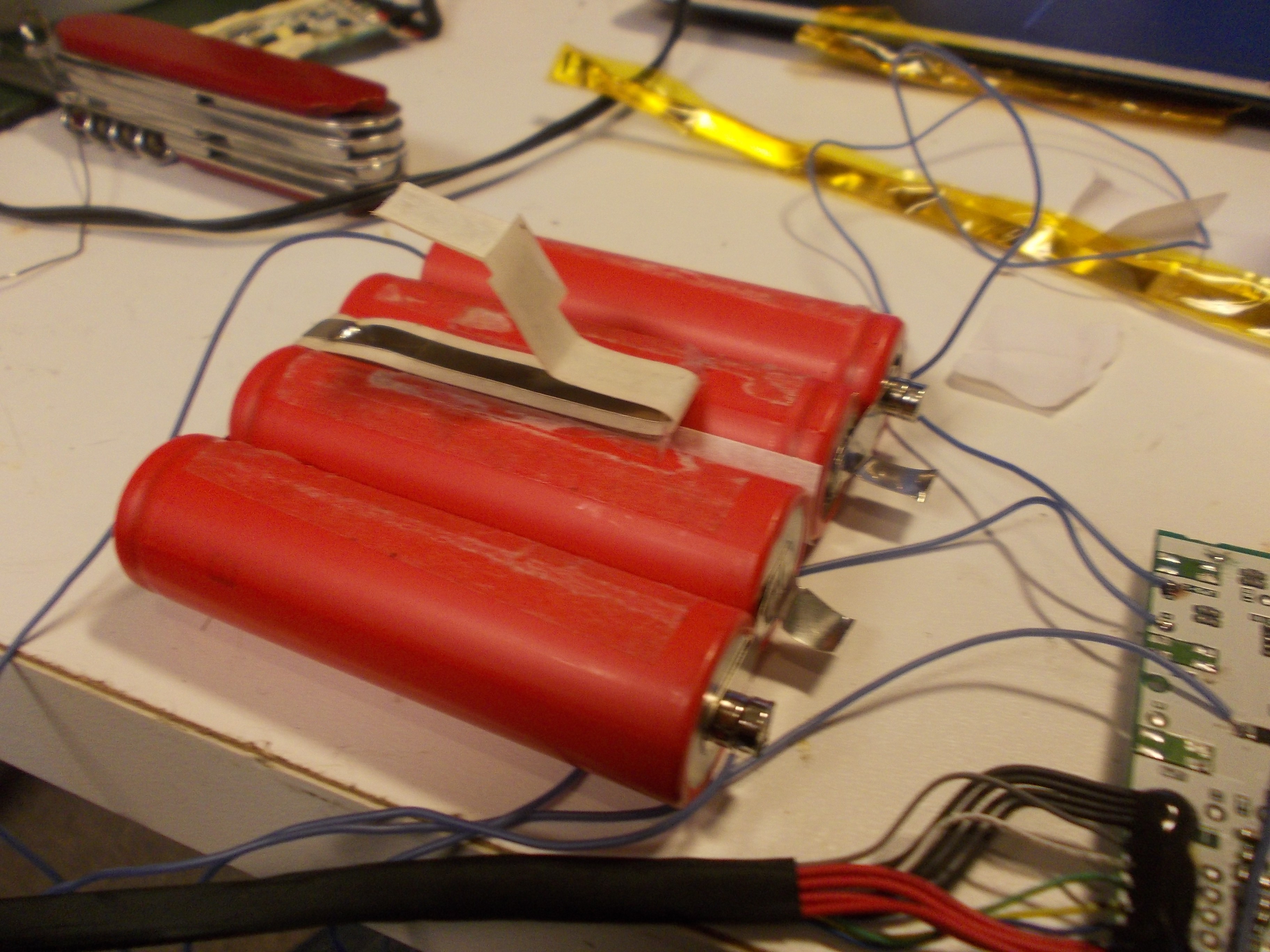

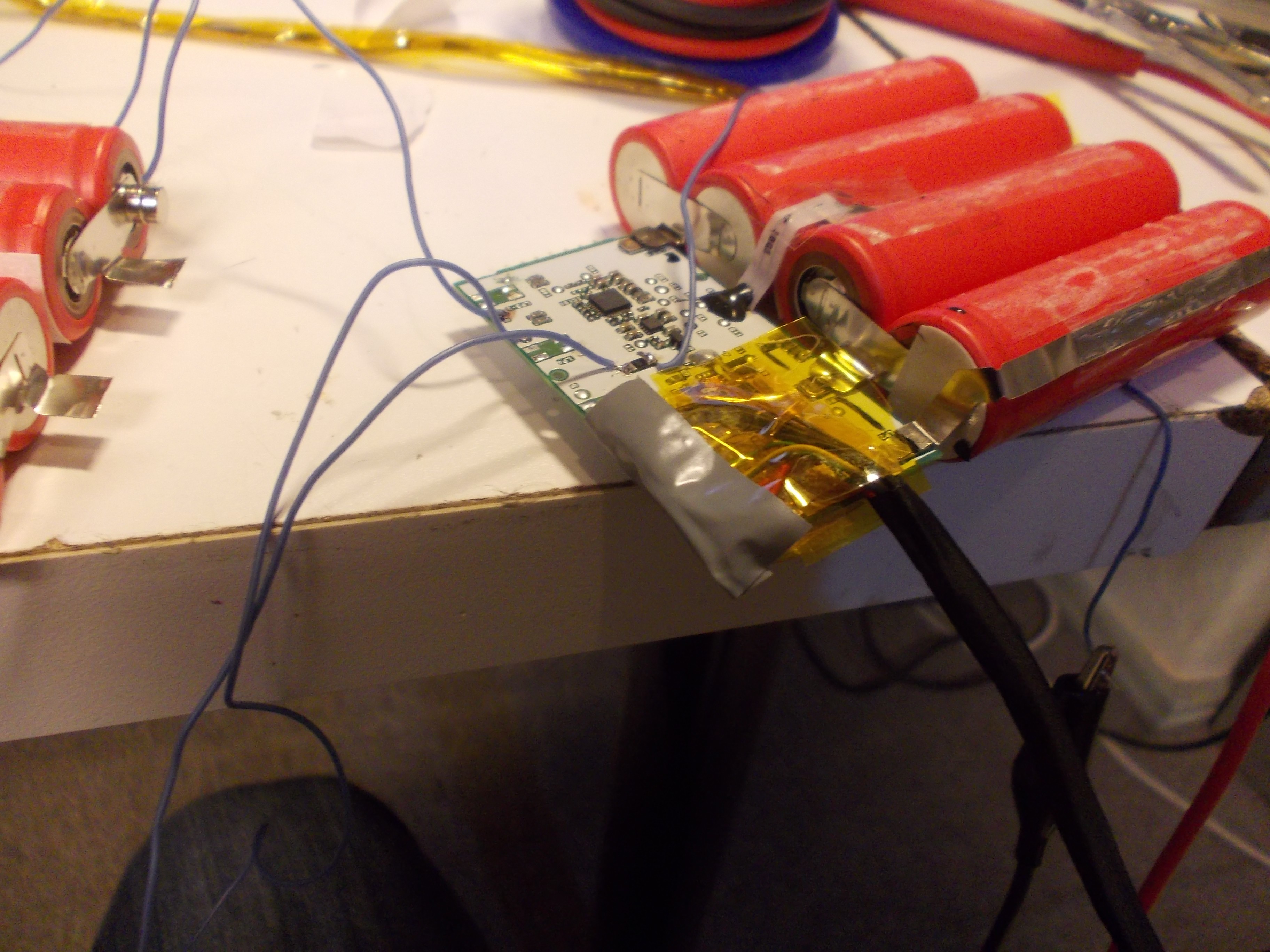

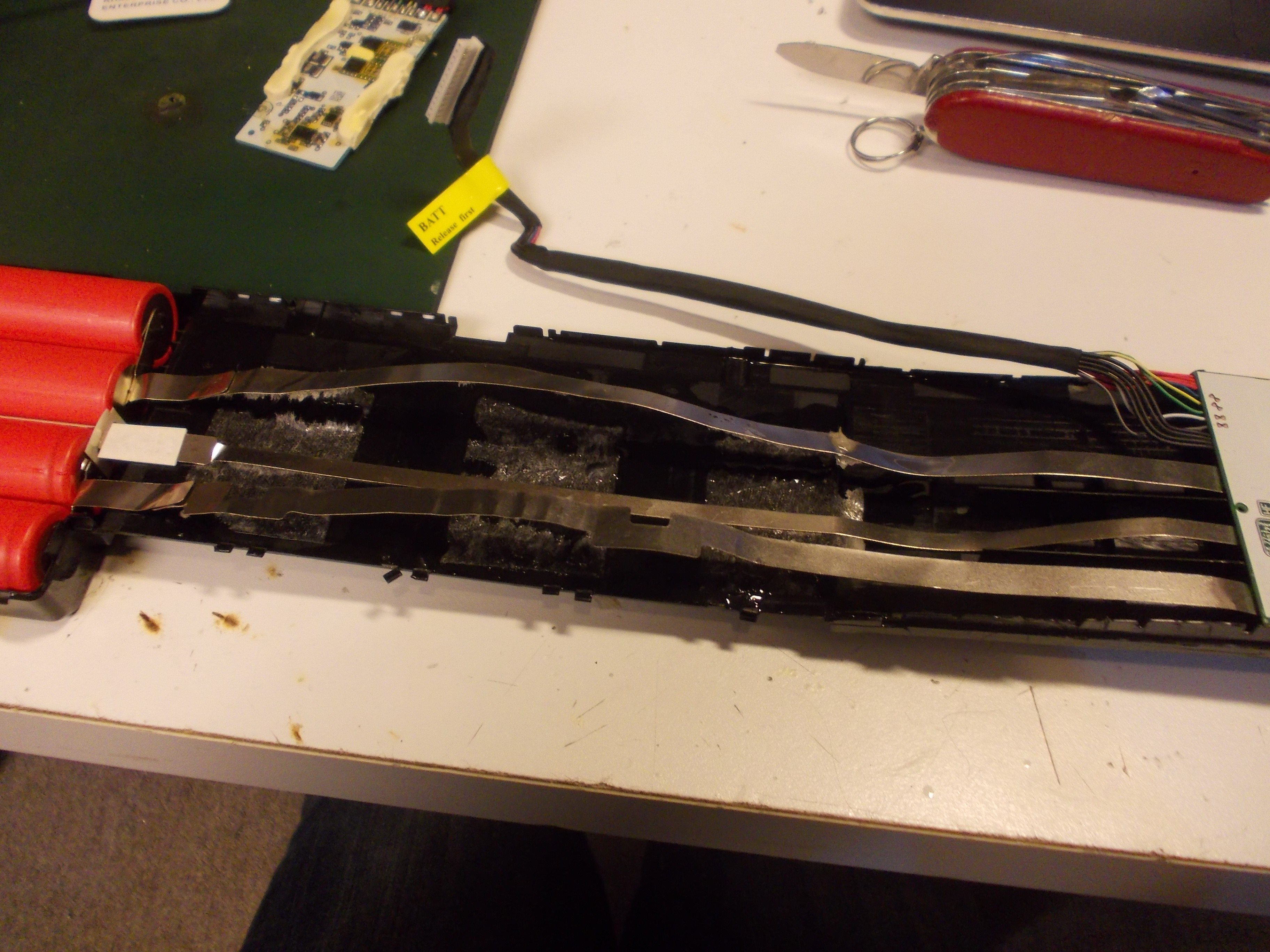

Solution - put guts of the 2. battery into the 1. battery case. However, I'd need to shorten these metal strips:

It's not as simple - as soon as you disconnect any of the metal strips, the battery controller bricks itself (rightfully so), as it needs to see valid battery voltages at all times without any interruptions - anything other than that is a sign of battery malfunction, and any laptop manufacturer wants to steer clear of that. Consequently, there's no simple way to "reset" a battery controller from such an occasion, either. However, with the power of magnets and kapton tape, I got it done.

Precautions:

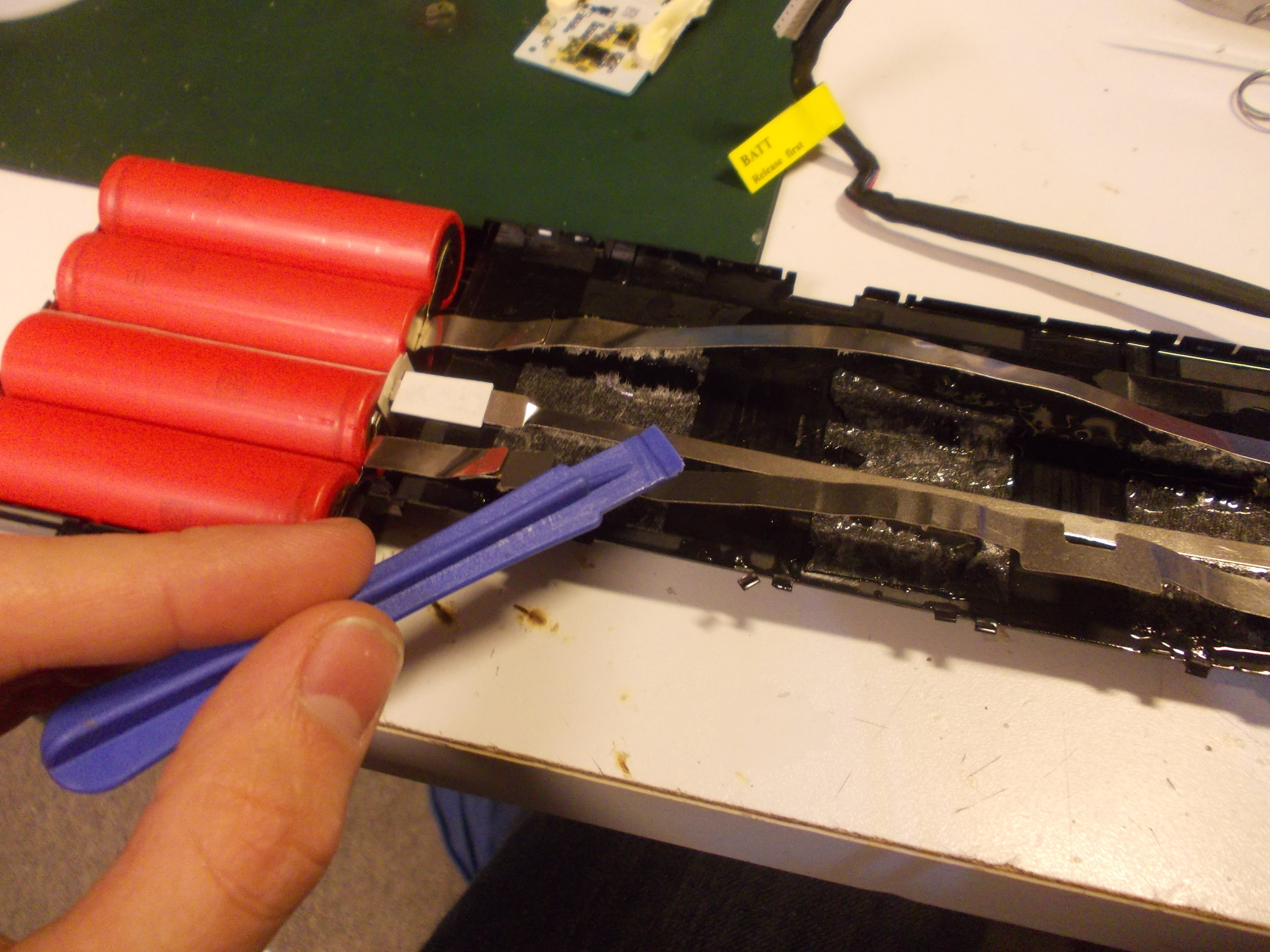

Metal strips glued to the case. Ungluing with isopropyl alcohol:

Then I realized that it's extremely important to avoid using any metal tools:

Then I realized that it's extremely important to avoid using any metal tools:Then I realized that, under no circumstances, I should allow the three metal lines to short together unless I want to lose my eyesight from the sparks that'd fly:

Kapton tape to the rescue.

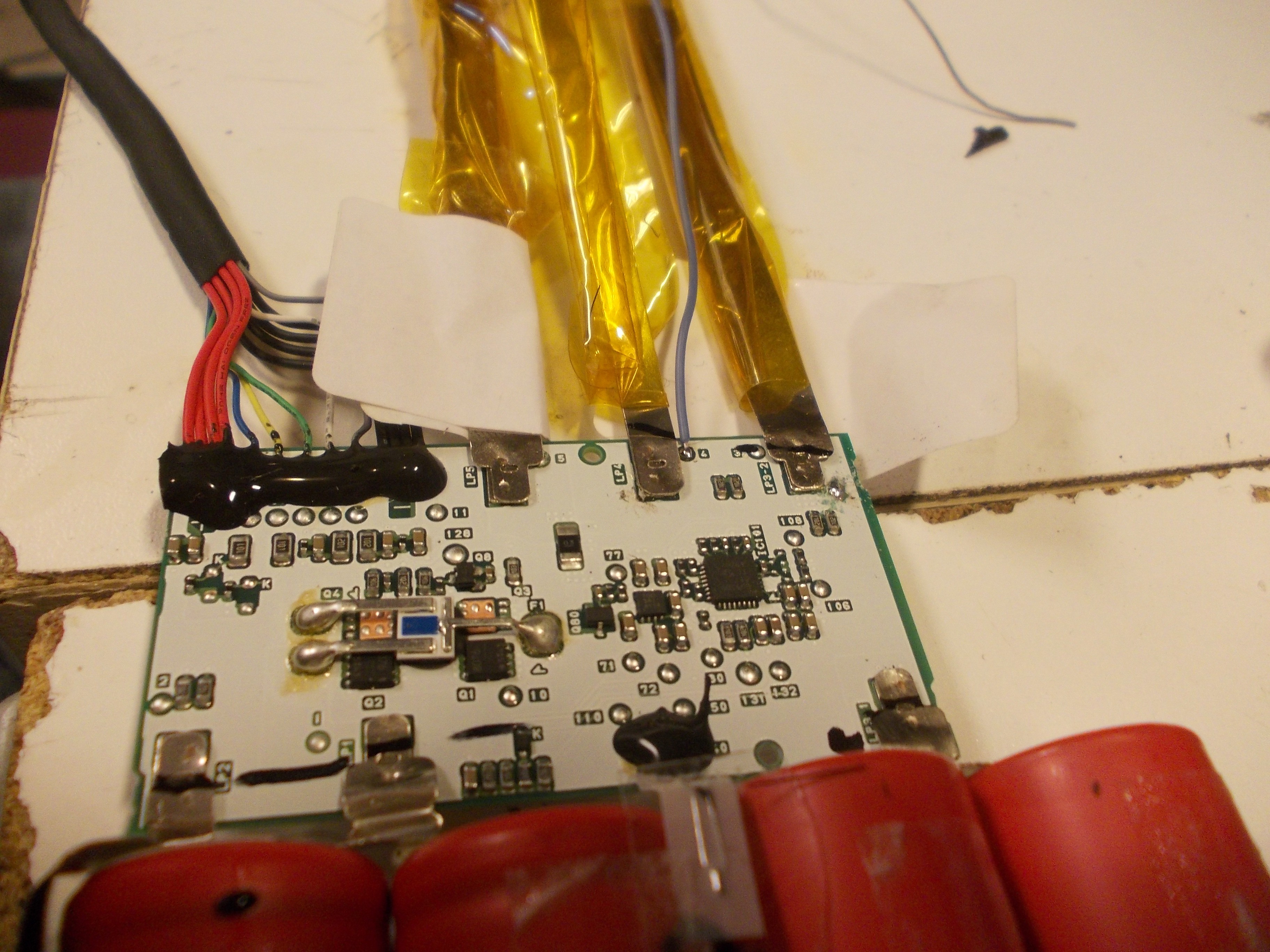

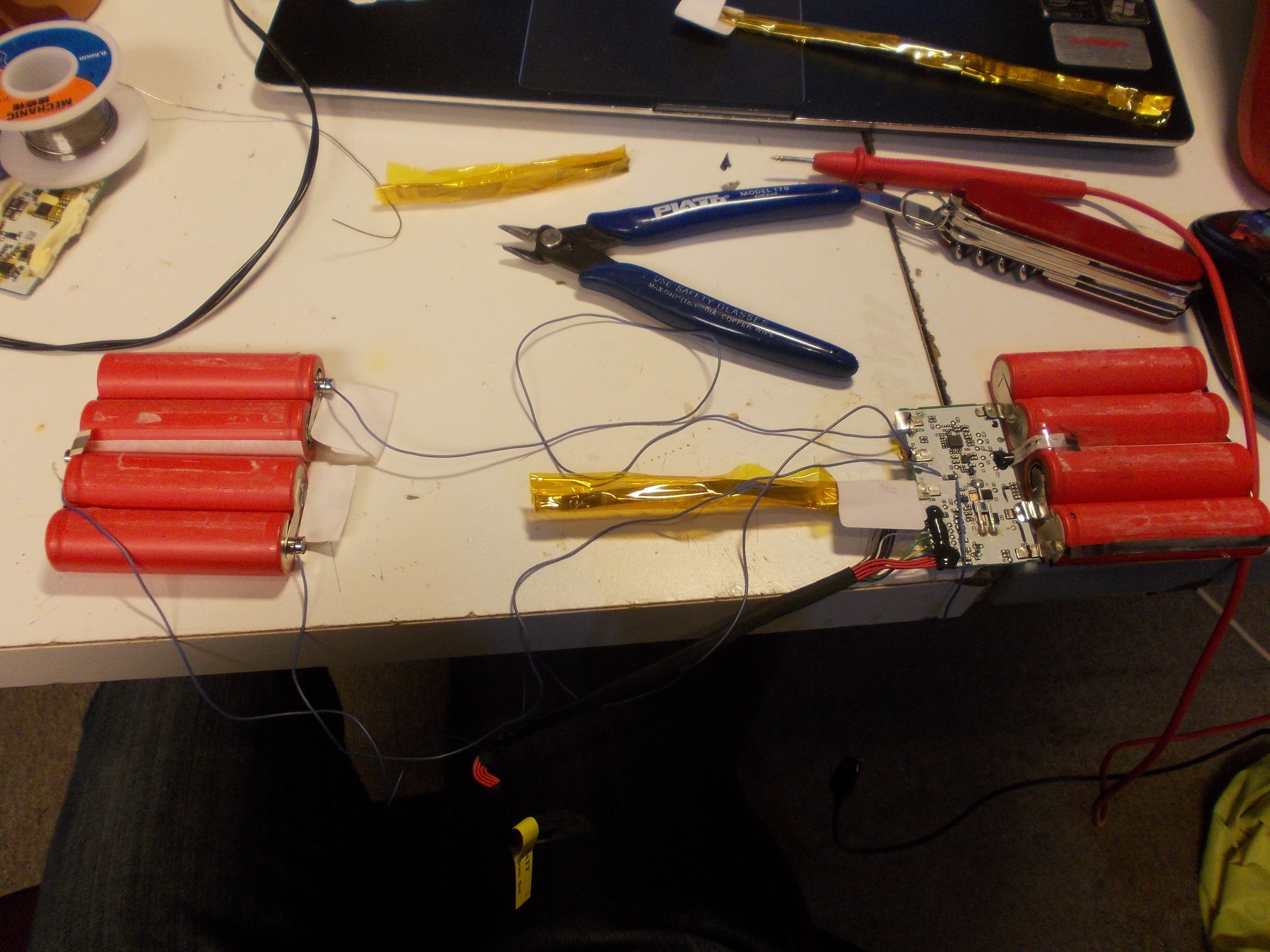

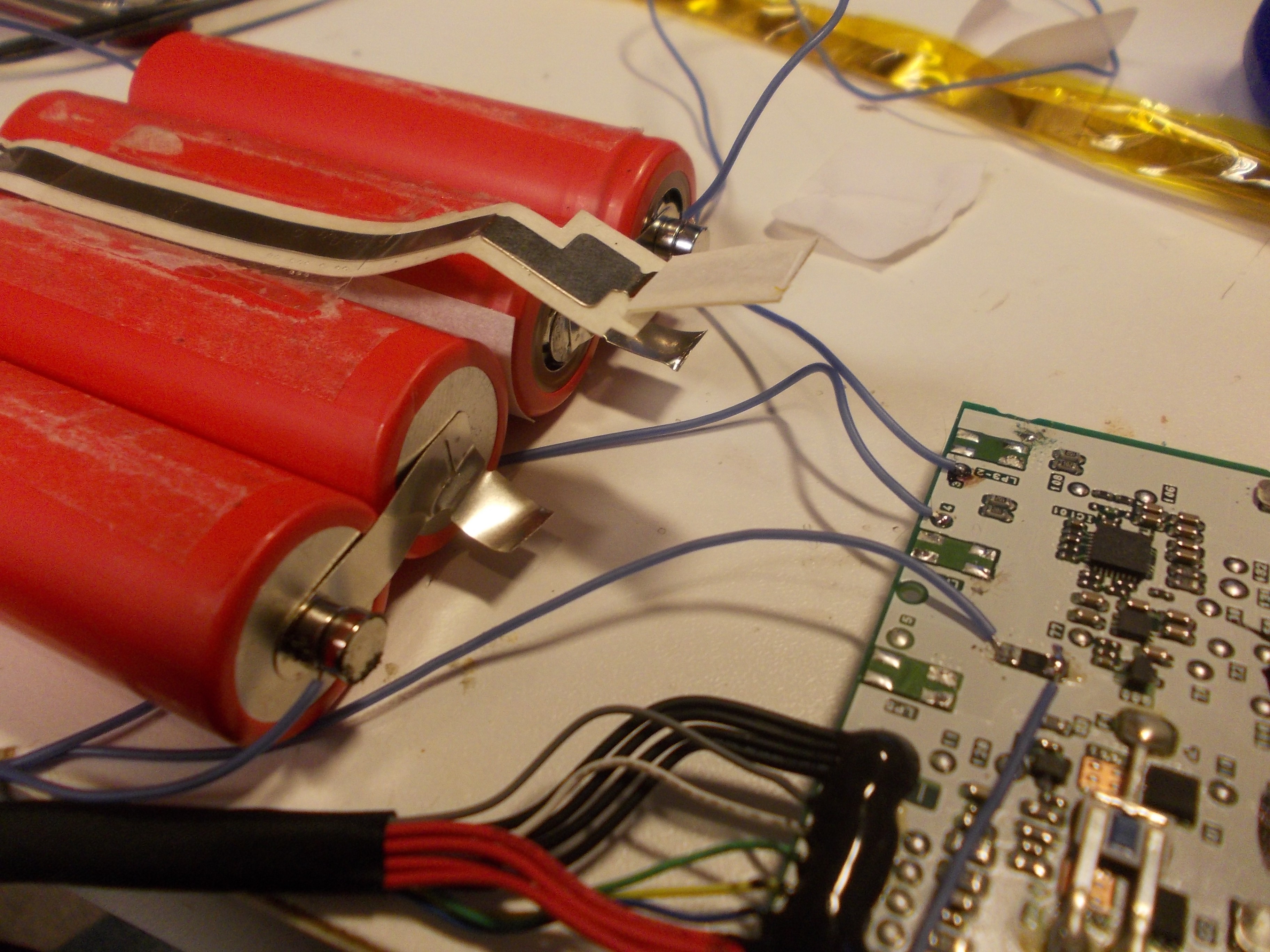

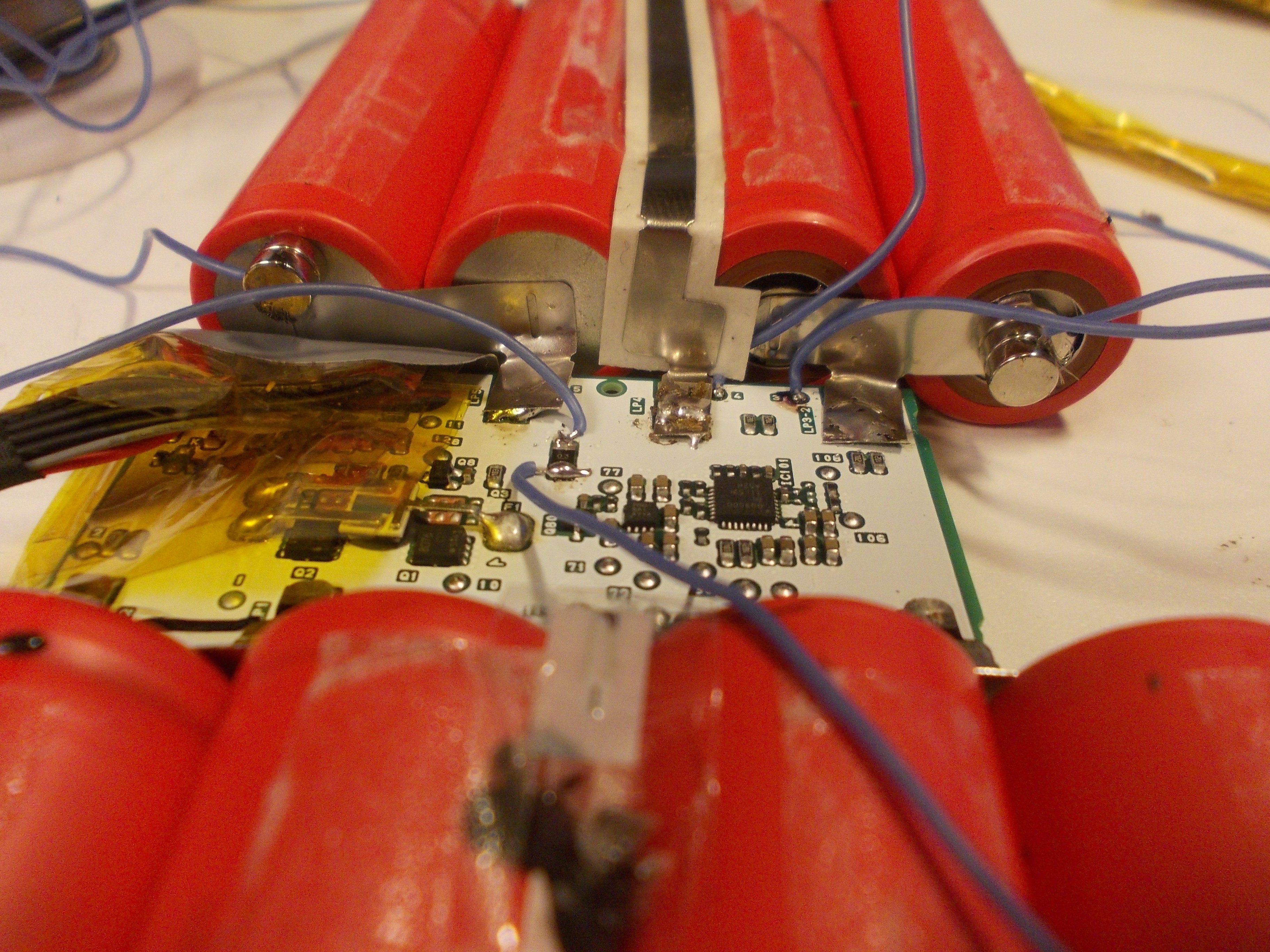

Now, what's the hard part, again? I need to shorten these metal strips and solder the batteries right next to the controller. However, I cannot disconnect any batteries from the controller, since as soon as I do that, it locks up.

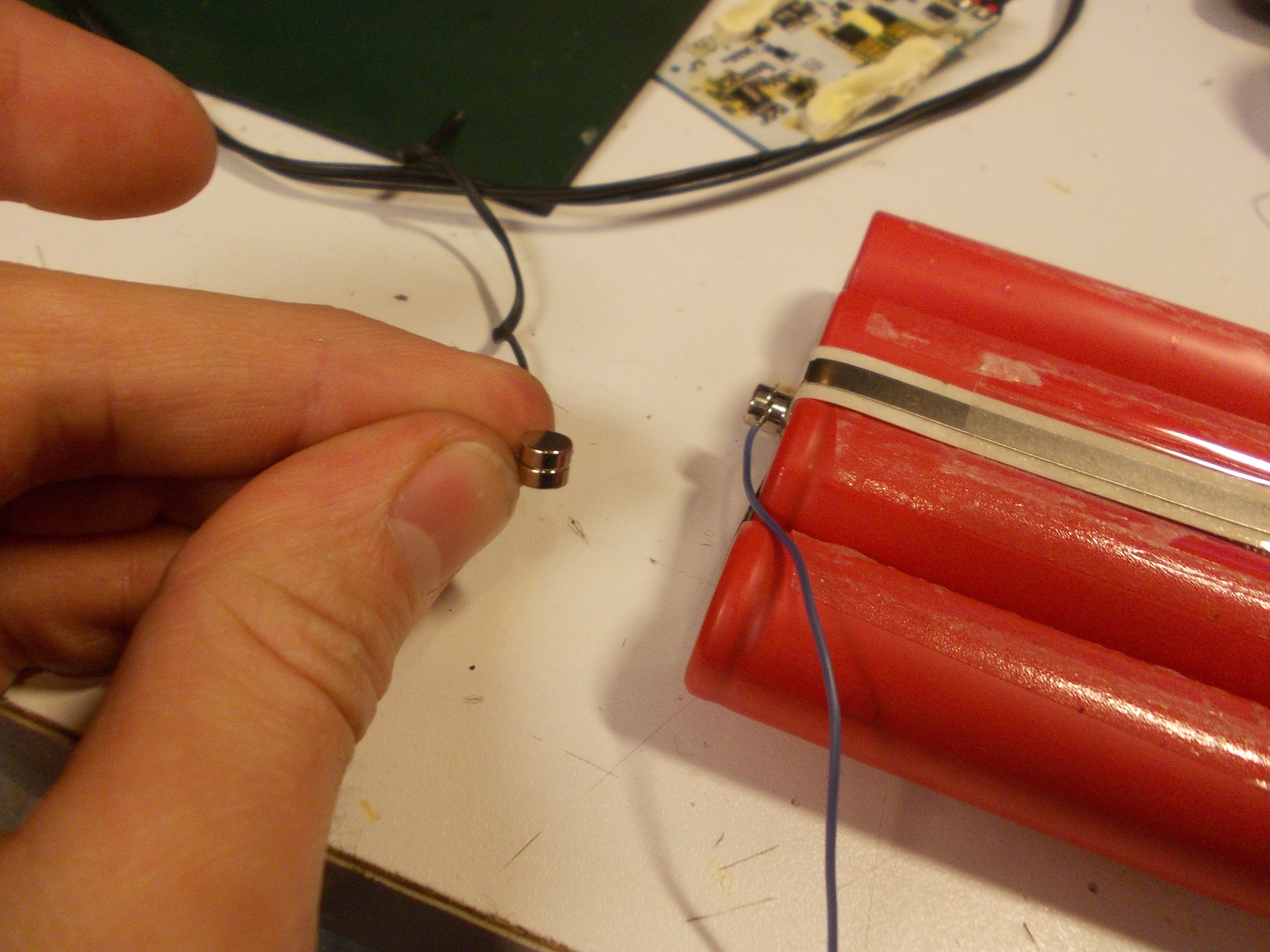

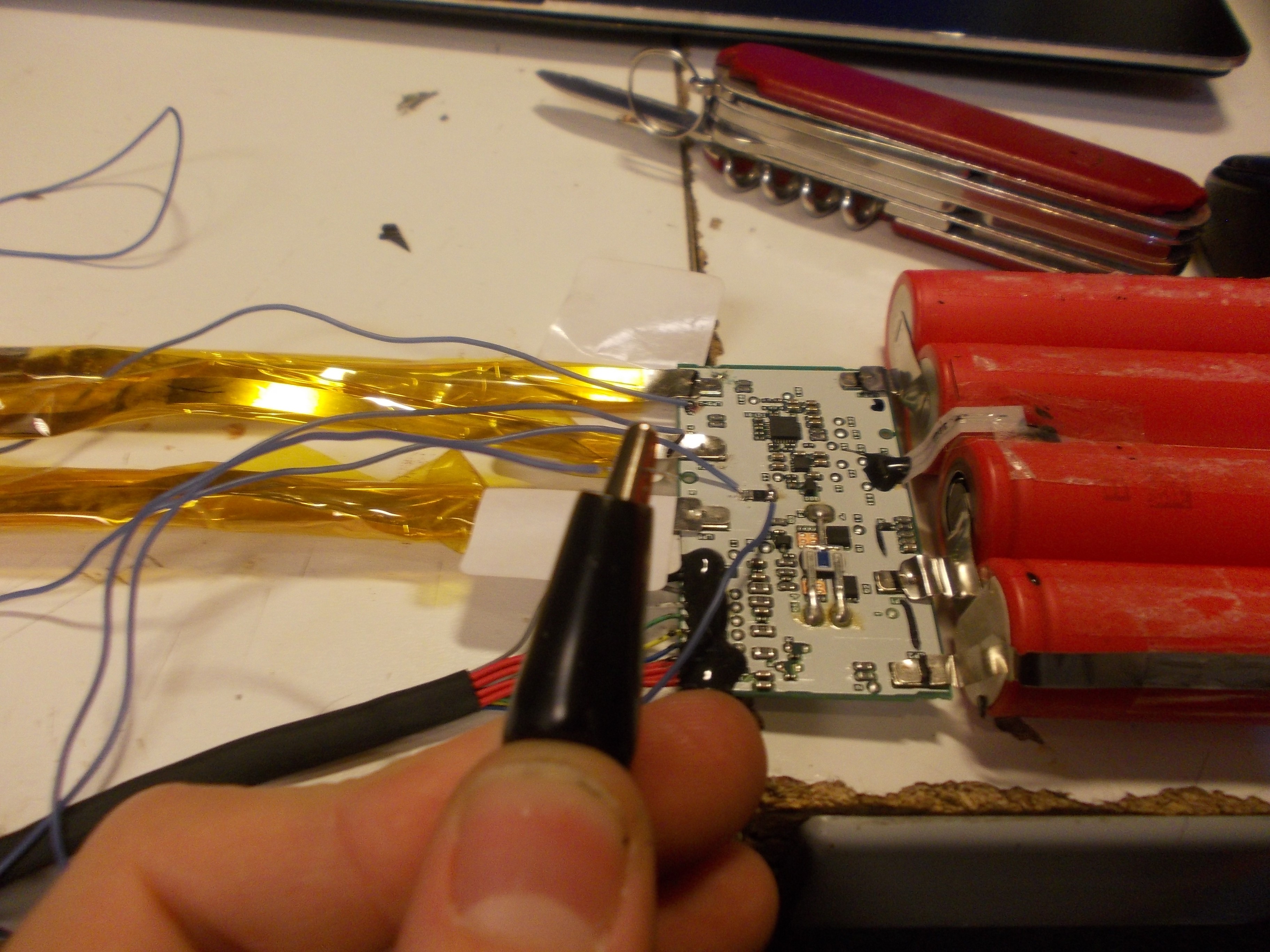

This is where magnets come in. I will make temporary connections using magnets and thin wires - they'll stick to the battery poles (as you cannot solder to batteries) and I'll solder the other end of the wire right to the controller. I cannot solder to magnets either, so I just use two magnets per wire, sandwiching the wire between two magnets so that an electrical connection is inevitable... you should check it with a multimeter anyway, who knows, maybe your magnets have a non-conductive coating.

First wire is attached and checked with a multimeter.

I have to solder wires to testpoints - not the same points where the metal strips disconnect, since I risk wires also desoldering when I desolder the metal strips, and then the controller instabricks.

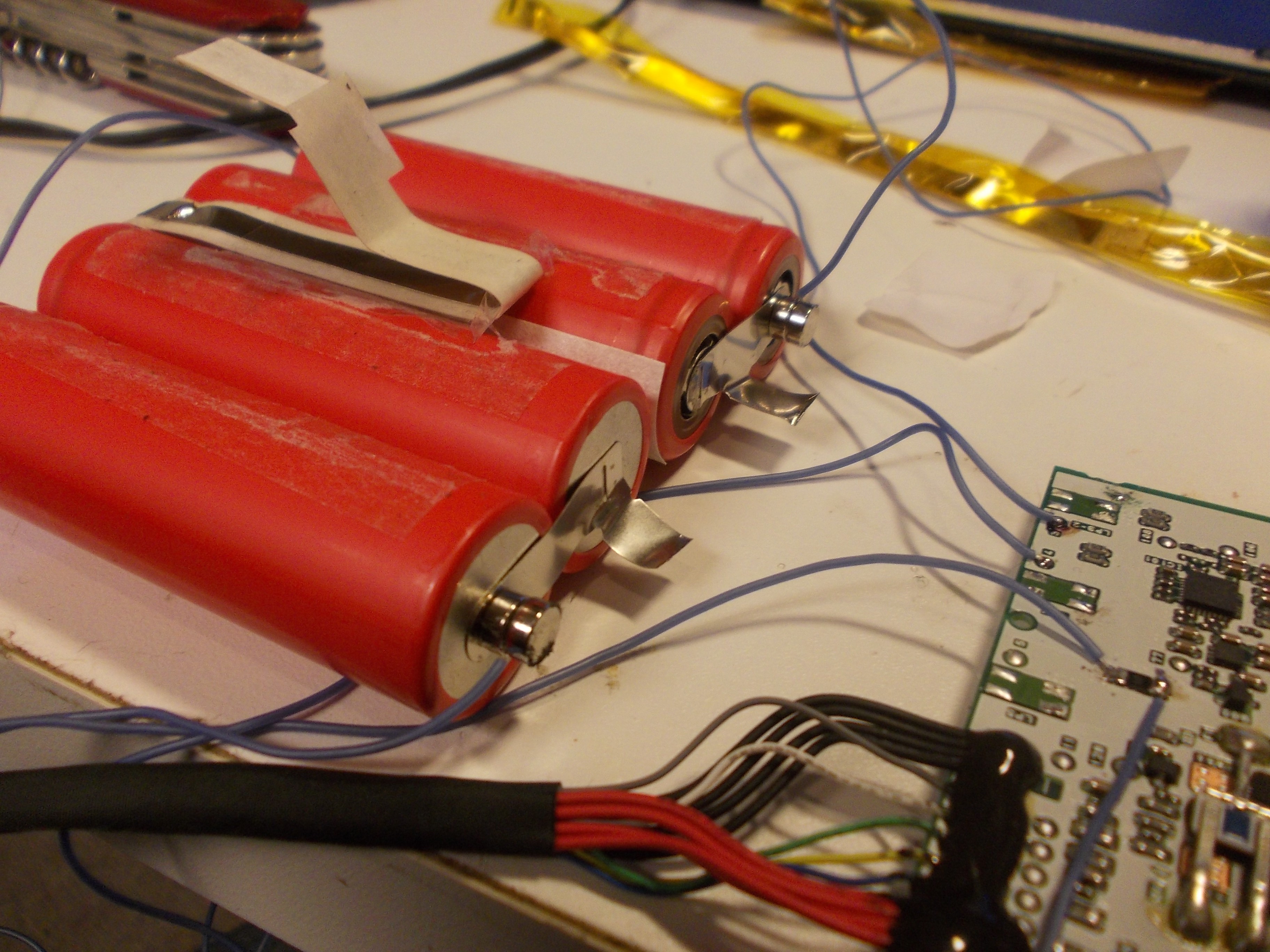

Attaching second magnet:

Uh-oh, the magnets seem to like each other very much. Might want to look out for that - avoid accidentally connecting two battery poles together through a thin wire - that'd quickly become a fire scene. First, connect the magnets, only then solder the wires to the controller.

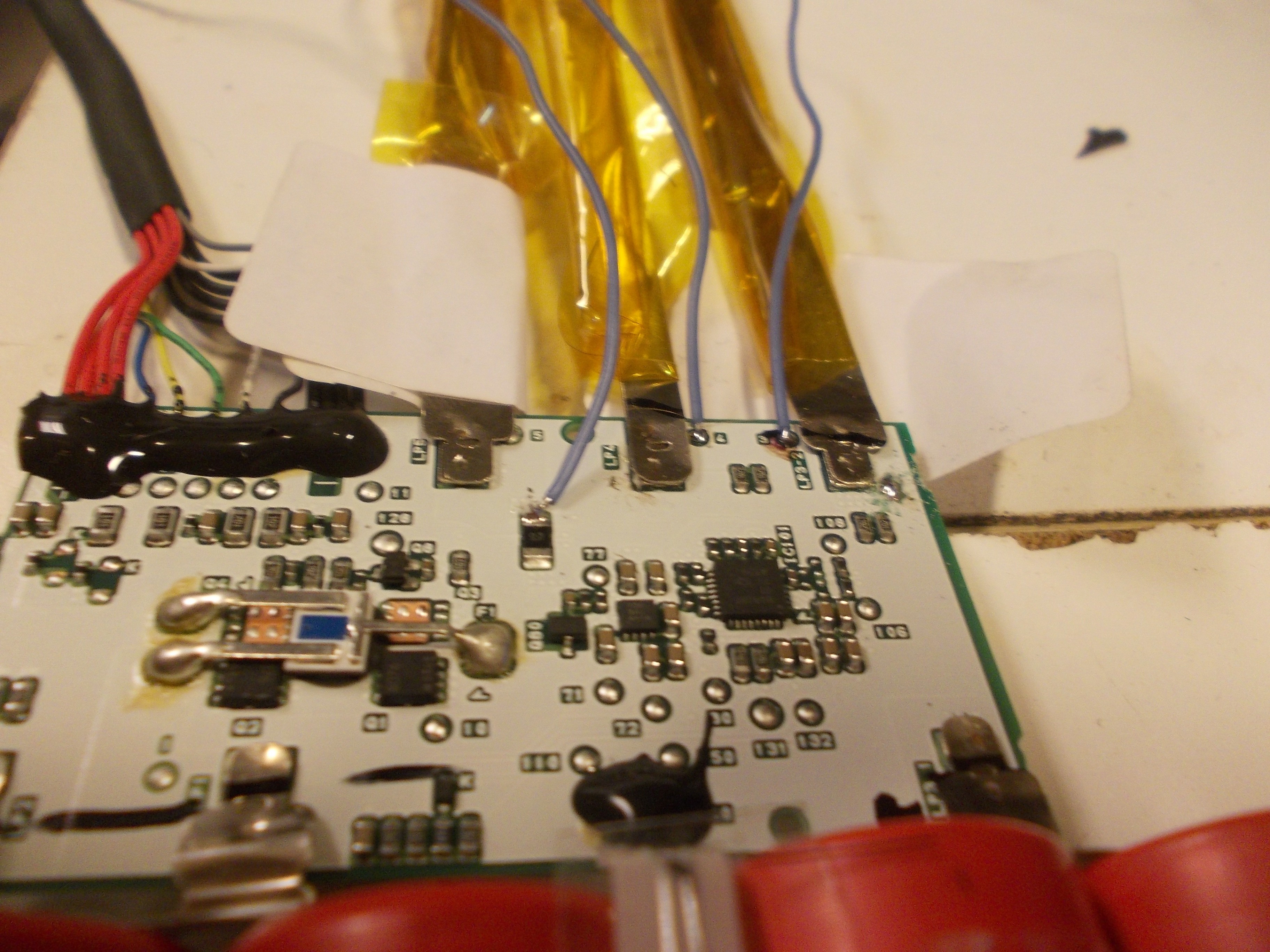

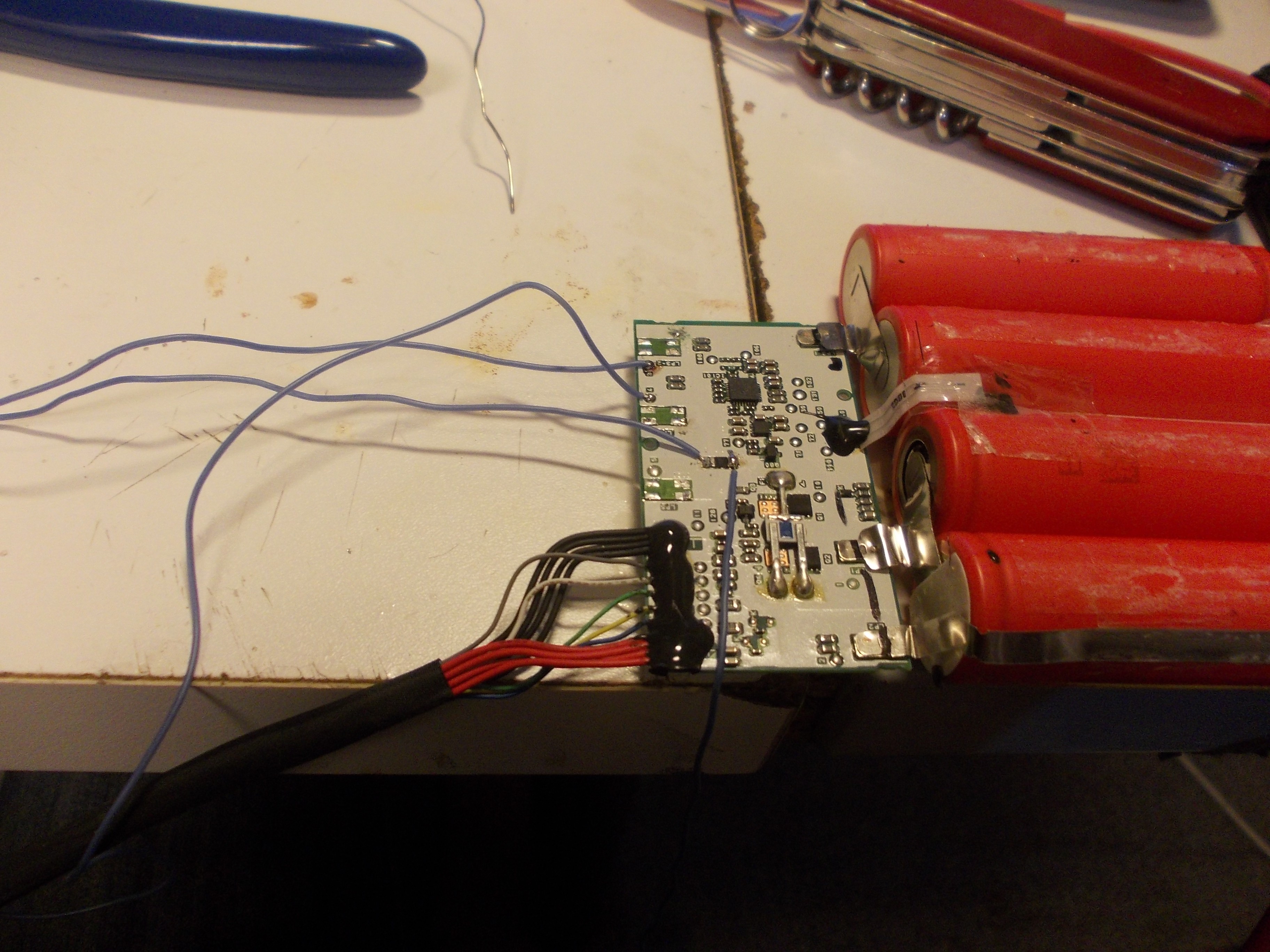

There isn't always a testpoint handy. Either way, all 3 wires attached and soldered.

I no longer remember the context for this picture - and the reason why there's a 4th wire attached to the PCB. Anyway, enjoy.

Moment of truth. Measured with a multimeter - all the voltages were still there. Yay! ... ?

Can never be too sure. From this moment, this is Schroedinger's battery.

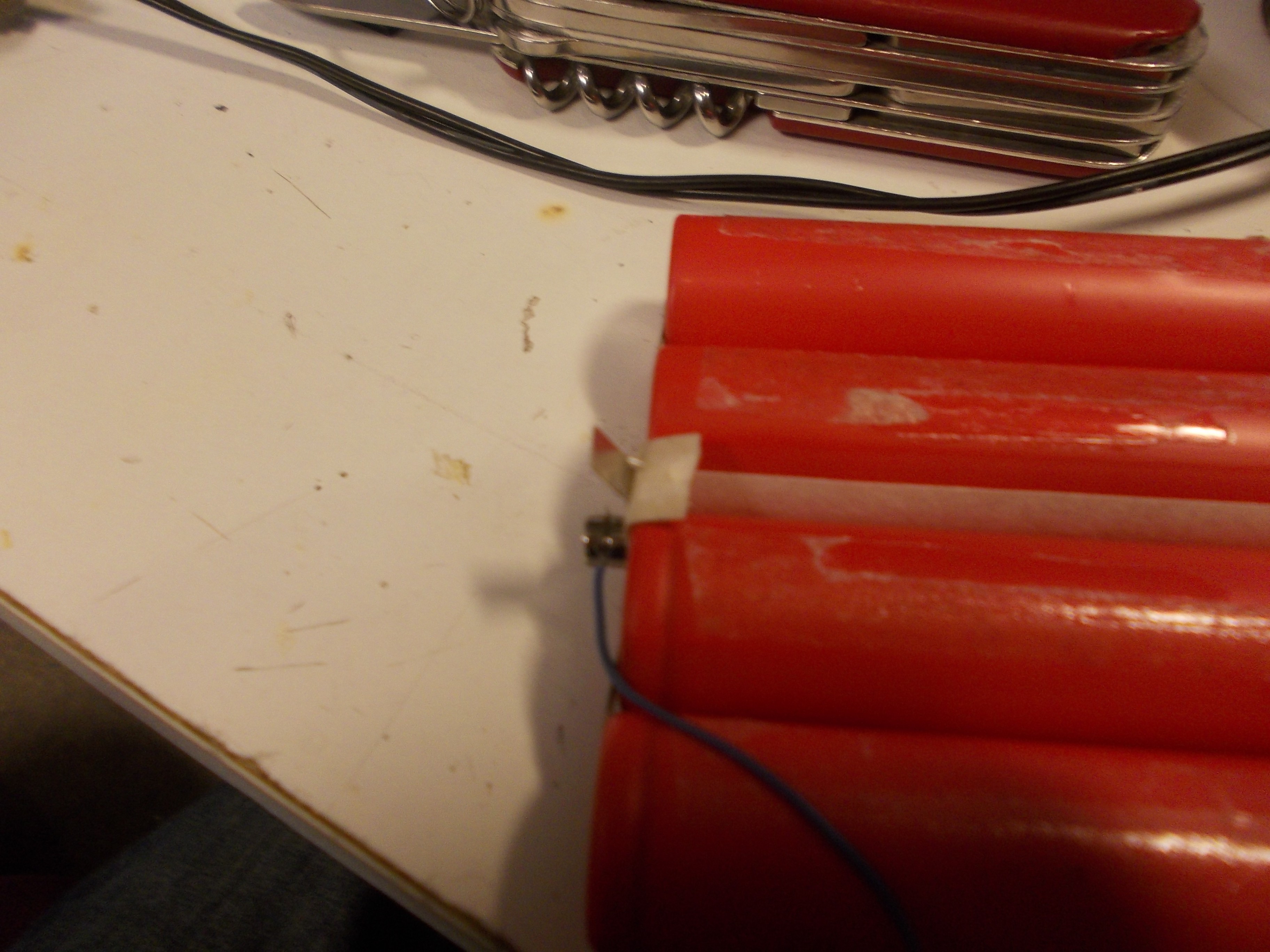

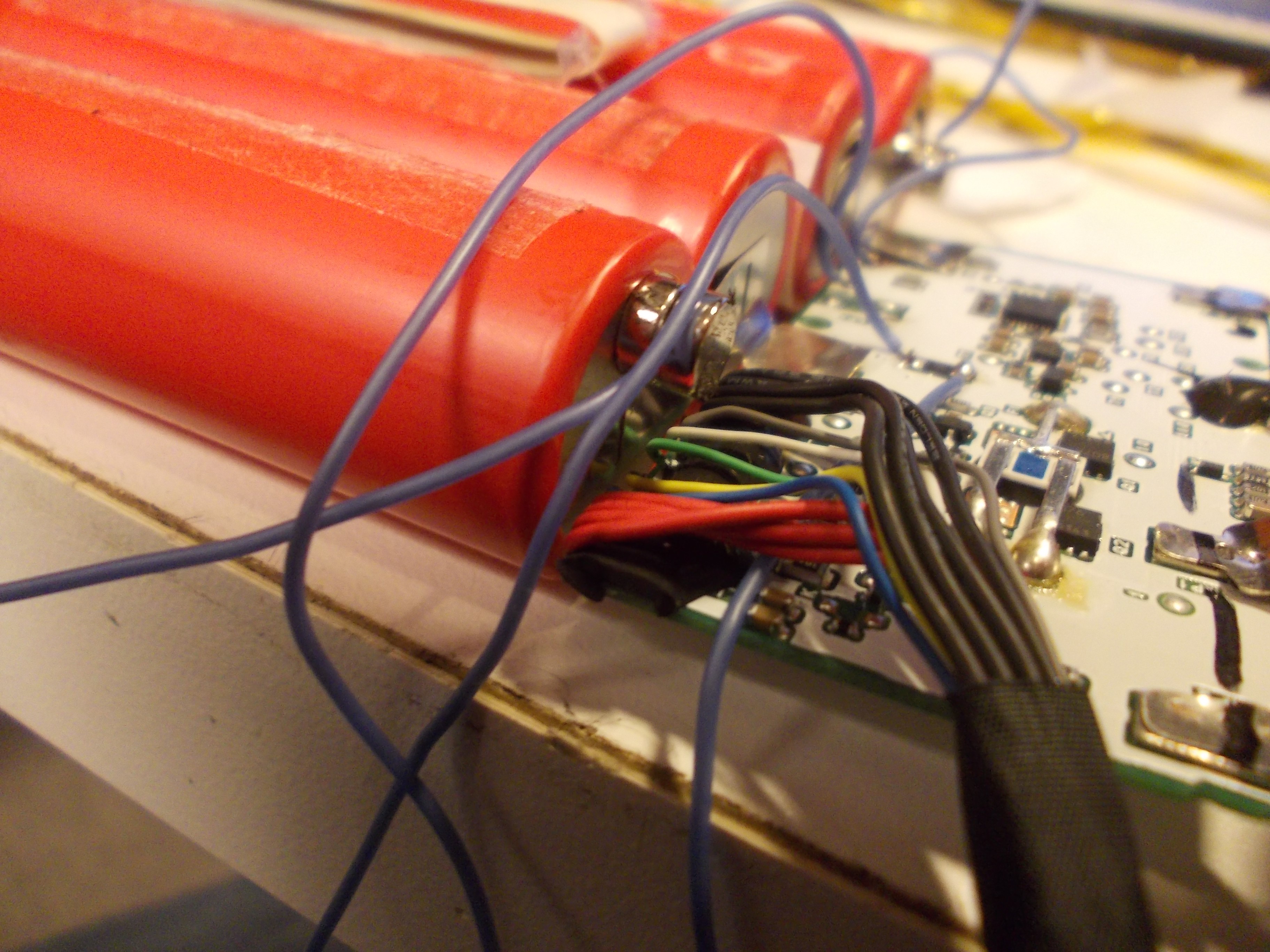

Snipping all the wires - from both ends. It's important to leave some metal so that I actually have something to solder to the PCB!

Covering exposed pieces of metal with stickers - just in case something shorts to something else.

Desoldered all the leftover pieces of metal from the controller board. Now, let's see how the battery fits...

Wait, I snipped this one way too short. Damn.

Extended with a metal piece that I clipped away before.

Hmm, the controller wires will interfere.

Should sorta work, but needs decent insulation.

Kapton + electric tape ought to do it.

I'll just go ahead and solder these, and remove the wires ASAP.

Test fit:

Oof #1 - the controller board sticks out the battery outline. Makes sense, the controller board was never meant to be in this case.

Well, it seems to fit. I won't be gluing it back together though - electric tape to the rescue again.

The battery worked and the laptop recognized it perfectly.

Oof #2 not pictured here - we had to dremel parts of the laptop case because of Oof #1 , as the PCB sticking out would interfere with the case. However, in the end, it did fit inside of the laptop.

Arya

Arya

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.