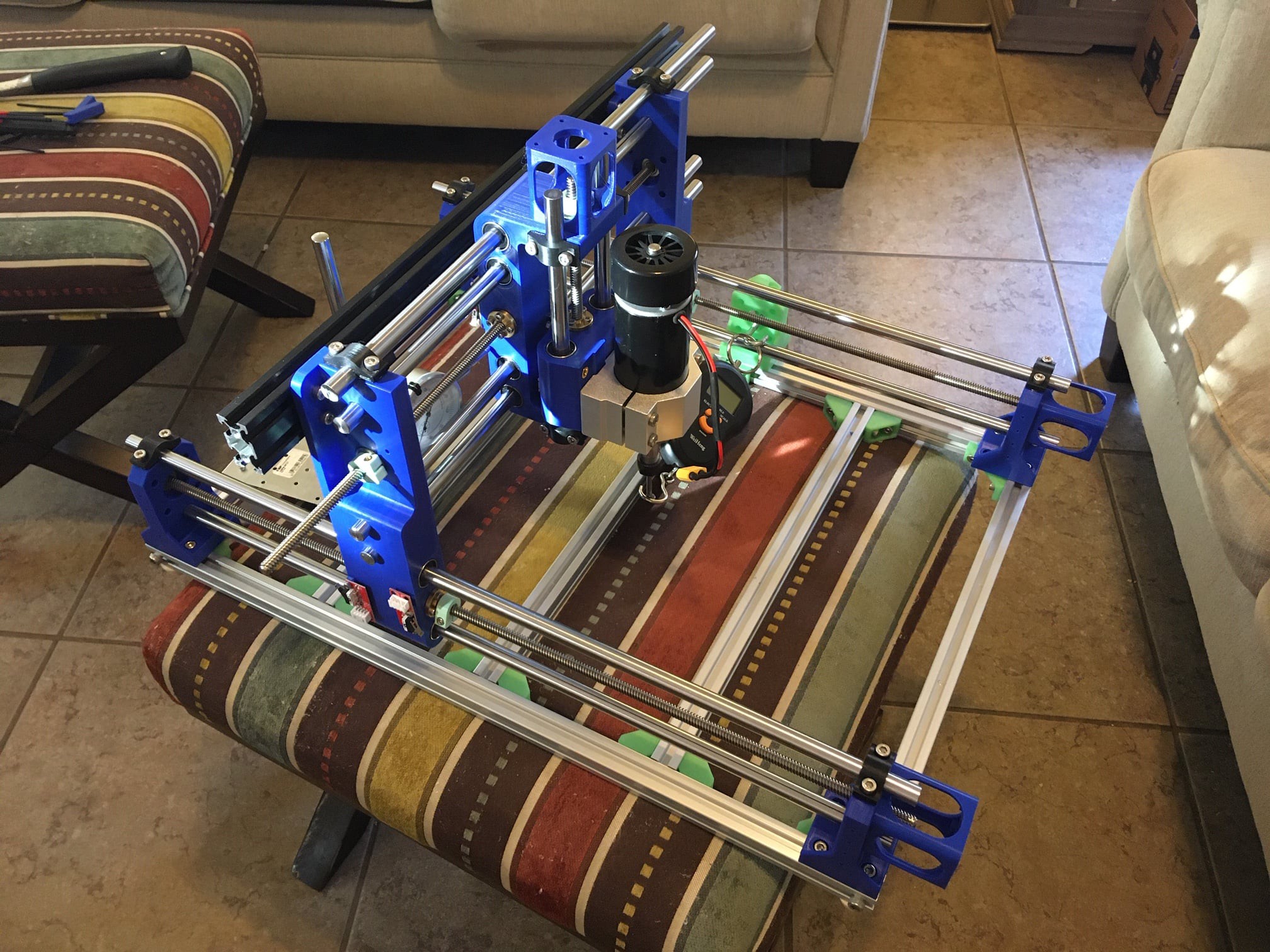

I posted most of my logs to a Facebook group, I'm going to copy them over here for posterity (so be honest!) Here is a log on testing I did to my v1 machine to see if more rods or a stronger x axis would help stiffen up the machine.

---

I have been trying to stiffen up my machine and have made some progress.

First I had not originally tapped the aluminum profile for the base but it turns out this adds much more strength than the corner brackets. However even with this the frame is not very solid, I'm going to convert over to using a 1" plywood base, it is much cheaper, simpler and stronger.

Next I made a Frankenstein rig to test out various ideas. I doubled up the 12mm rods on the x and y axis and added in a 4020 aluminum profile to anchor the two y carriages together. Then by removing parts I was able to test the relative benefit of each addition.

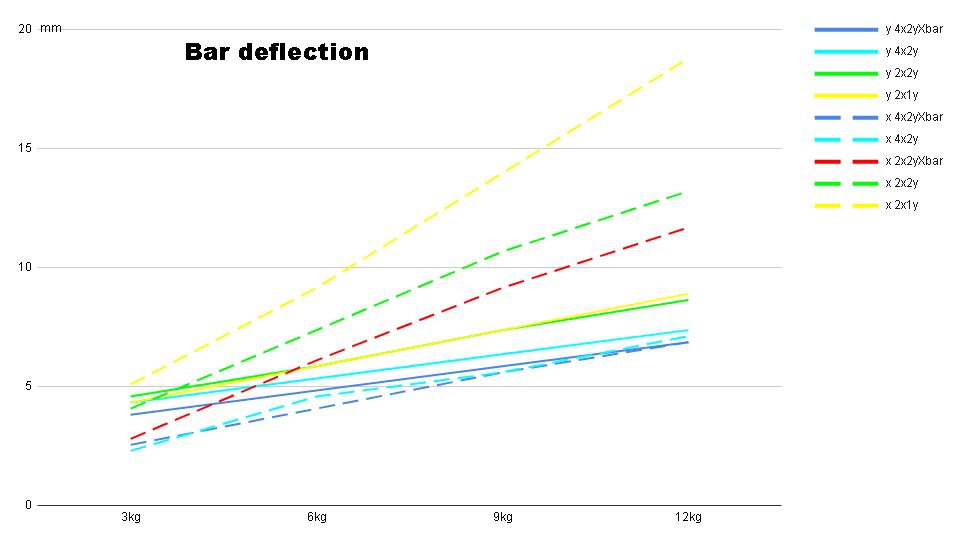

I setup my dial indicator on the x carriage measuring deflection in the x and y axis. I did not measure deflection at the tip of the tool because I wanted to only detect the benefits of the extra strengthening of the x and y axis and did not want any extra noise.

In the attached chart you can see the x and y deflection with 4 or 2 rods on the x axis, 2 or 1 rods on the y axis, and with or without the 4020 profile attached. You can see that the 4020 profile has almost no benefit at all. It is possible that tapping it and mounting it via the ends would have a small extra benefit but I doubt it.

Doubling up the x and y rods has the most benefit, but doubling the y rods alone has a rather large benefit on its own, especially in the y direction. I suspect that in the x direction the extra y axis rods actually reduce lay over of the uprights.

Honestly going with 16 mm rods would probably be a more cost effective and stiffer solution. There is still a visible amount of deflection to be had just by pushing on the x and y rods individually. It is something to experiment with later, but for now I will see how far I can take things with what I have.

Oh and spacing the x axis rods out seems to really tighten things up as well.

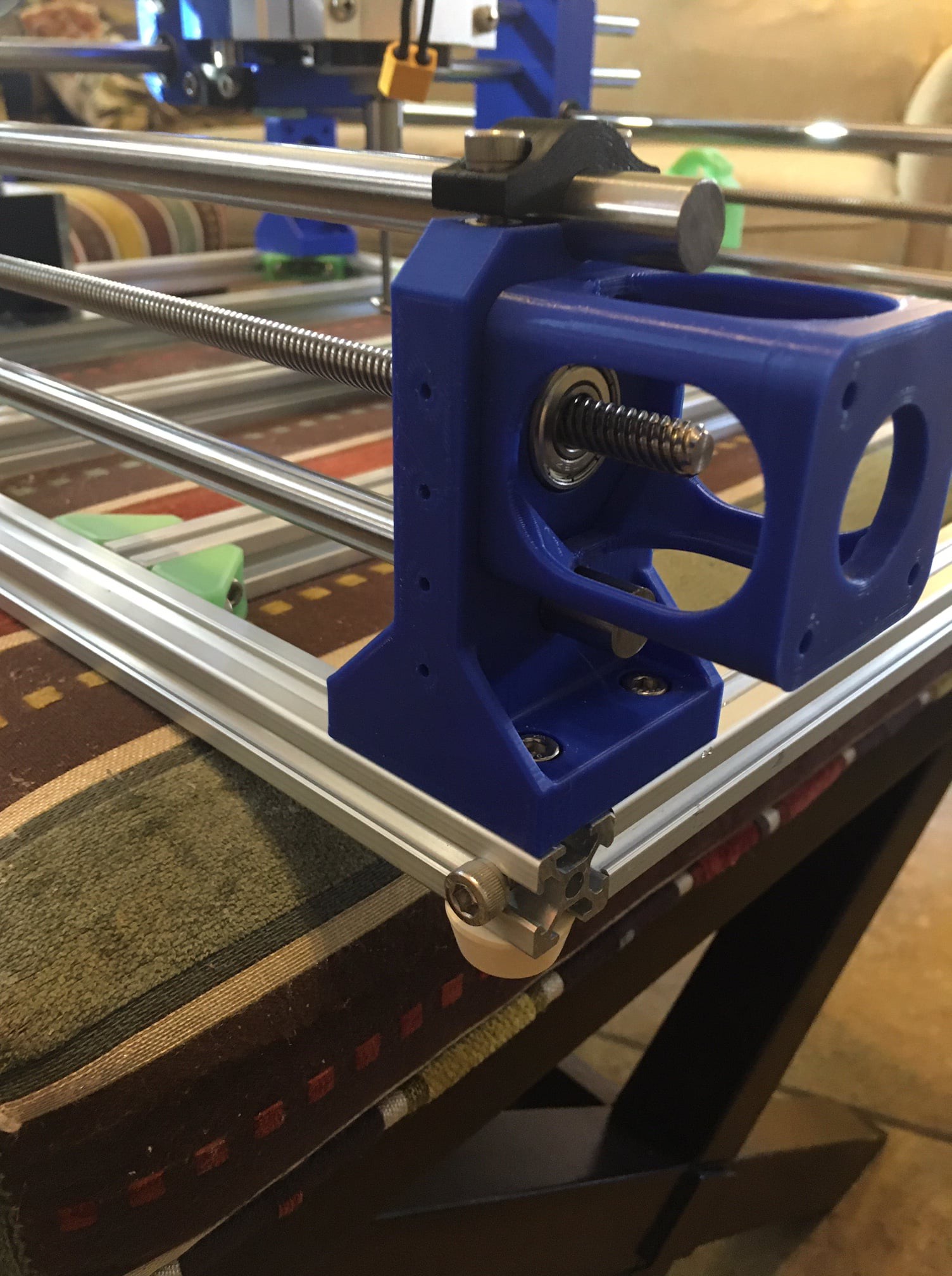

Finally to reduce backlash I used a brass nut on one side of my carriages and a Delrin nut on the other. Putting pressure on the Delrin nut to take up the play. This has made a big difference and works much better than the cheap anti backlash nuts you see on alliexpress. I figure using both materials is safer, the brass will act as a backup if the Delrin fatigues.

I need to take these ideas and redesign the rig, I have too much z height for starters. But at least I have a better understanding of the relative benefits of each change.

David Tucker

David Tucker

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.