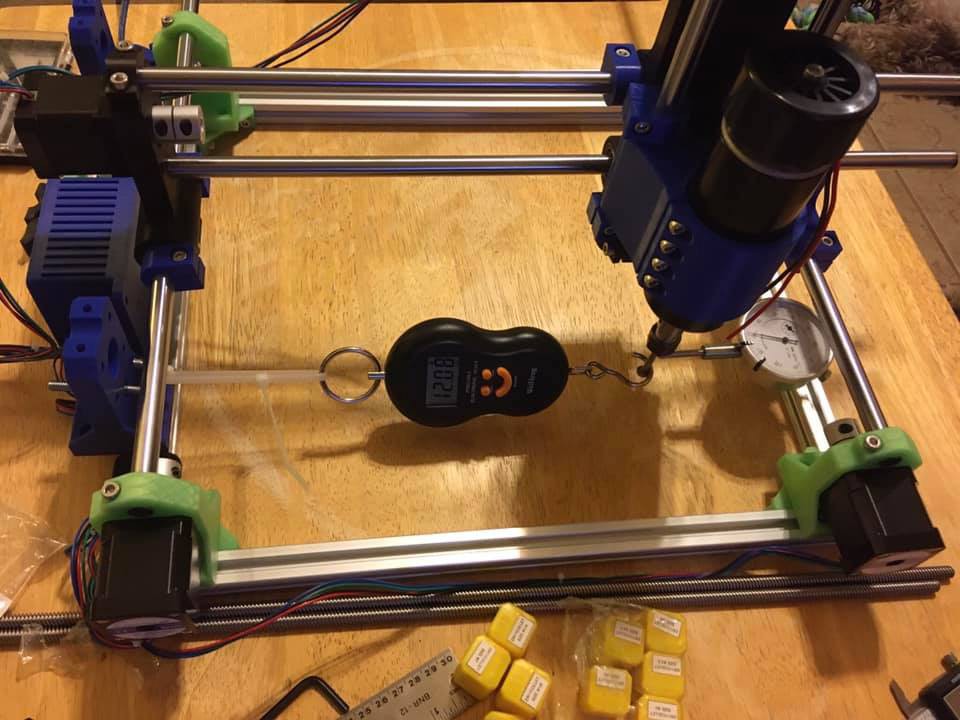

I’m still waiting on some parts so I’m continuing to test with the parts I have. Since I’m missing some lead screws and extrusions I decided to make some clamps for the 12mm rods so I can continue my strength testing. I only have 400mm extrusions so far so the setup is basically a square.

Applying a 12kg load to either the x or y axis at the tip of the tool (using a nail as a stand in for a bit) I’m measuring 4mm of flex in either direction. Interestingly in the y direction I’m also measuring 4mm of movement on the z axis. Basically the x axis is twisting from the offset load.

It appears the flex is almost completely in the rods. It is the weak point in the design.

Anyway this was a really rough test. It is possible the nail is flexing more than I thought. I need to run it again while measuring at more points to verify where the motion is coming from.

David Tucker

David Tucker

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.