The air sources I tested were as follows:

- Bostitch 6 gallon pancake compressor set to 15 psi ($150)

- Simple Deluxe 1189 fish pump compressor ($45),

- Sunrise (DeVilbiss) model 46502 compressor/nebulizer (recycled)

- Aqua Culture 20-60 gallon air pump ($15)

- 24v radial fan from an ender 3 to see if an air compressor is even needed ($1)

First for the noise, I just happen to have a Pyle dB meter laying about. I measured the dBA right next to each compressor as well as 5 feet away, all within my enclosed garage.

I also measured the max PSI each compressor could produce when no air flows, as well as the PSI when air is flowing unrestricted through my 2 mm nozzle. The results are summarized below.

| Name | 0 ft dB | 5 ft dB | psi (air off) | psi (air on) |

| Bostitch 90 psi (15 psi regulated) | 91 | 81 | 15 | 15 |

| Simple Deluxe | 64 | 52 | 5 | 3.5 |

| Sunrise | 78 | 68 | 19 | 3 |

| Aqua Culture | 46 | 35 | 3 | ? |

| 24v fan | 54 | 42 | ? | ? |

The ambient noise in the room was hovering between 30-50 dB, any measurements below 50 dB are probably not very accurate and can be considered basically inaudible.

The Sunrise compressor is capable of producing a surprising amount of pressure, but once you let the air flow the pressure falls dramatically. That plays out below with it not working as nicely as the simple deluxe air pump. The big news is that the simple deluxe manages to be significantly quieter than the Bostitch. It can't compete on the pressure level but if it can get the job done it will be great.

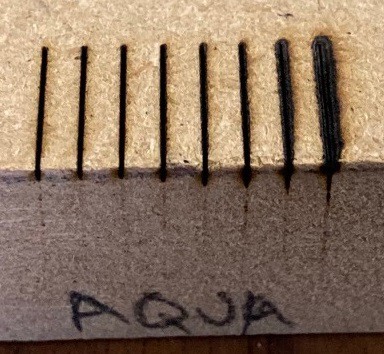

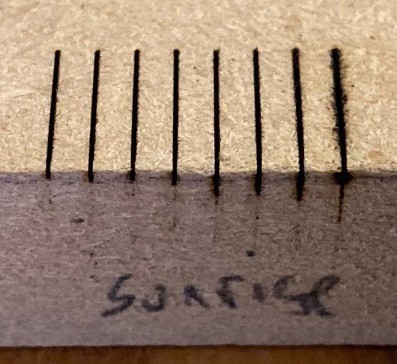

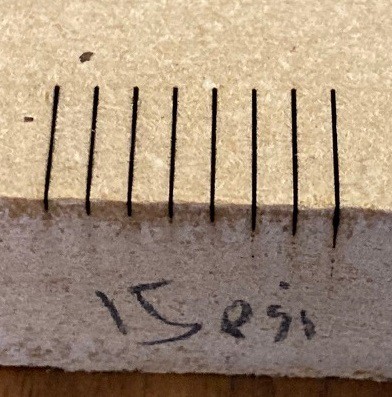

The next step was to evaluate how each works when pushing air through my over the lens nozzle with a 2mm orifice (or blowing at the side in the case of the fan). To test this I wrote a program to draw a series of lines, focused at the top of the work piece at 80% power and at speeds from 400 mm/min to 50 mm/min in steps of 50. The test pieces are shown below.

Looking at these results, the radial fan is worse than no air assist. It blows the smoke back onto the workpiece and just makes a mess. No air is not very good, even a fast cut has a lot of extra scorch damage. The Aqua Culture pump is where we start to really see the value of air, it is more than enough to improve the lines as long as the laser is moving fast enough that we don't start a fire. However at slower cutting speeds (deeper cutting depth) we still see a lot of scorching. The great news is visually the simple direct pump is almost as good as the compressor at 15 psi. We know from previous tests that the compressor at 30 psi cuts even better, so the compressor is always the winner but a $45 aquarium pump is both dramatically quieter and still good enough for most work.

I tried my usual trick of using feeler gauges to measure the depth of the cut. However for some reason I am not seeing a significant change between the cuts. There is a large jump in depth with power, but going form no air to 15 psi only saw a 0.2 mm increase in cut depth. Part of the problem may be that I used a larger 0.1 mm thick feeler gauge rather than the 0.02 mm thick gauge I used last time. The 0.02mm gauge is paper thin and I was worried about damaging it. Cutting the speed in half did roughly double the cut depth.

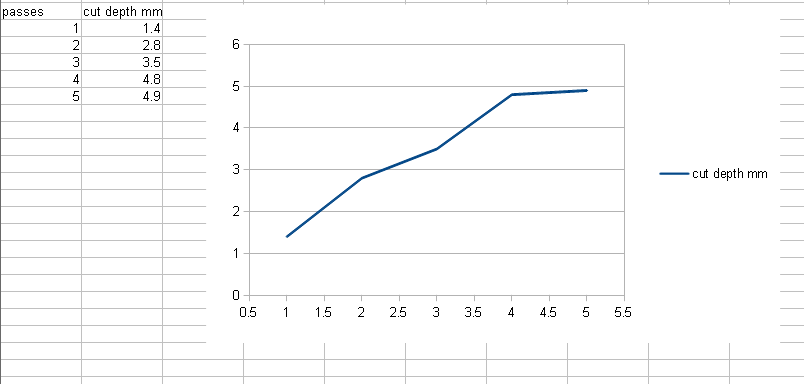

I wrote one more test program that runs the laser at 150 mm/,min, 80% power, with 15 psi of air and that takes 1 to 5 passes across the material, lowering the laser by 1 mm on each subsequent pass. This proved to be very effective, with each pass deepening the cut by approximately 1 mm. Things seemed to flatten out on the 5th pass, it is not clear if that is just the end of what the laser can do or if the bottom of the cut was just deep enough that we would need a 6th pass to bring the laser back into focus on the bottom of the cut.

David Tucker

David Tucker

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.