I have been thinking for a while now that these projects updates are lost in the noise. So I decided to make a new hackaday project that summarizes my work (to some extent) so that maybe someone can find my work eventually. I don't plan on really maintaining that project, it is just a loss leader (or a desperate cry for attention).

---

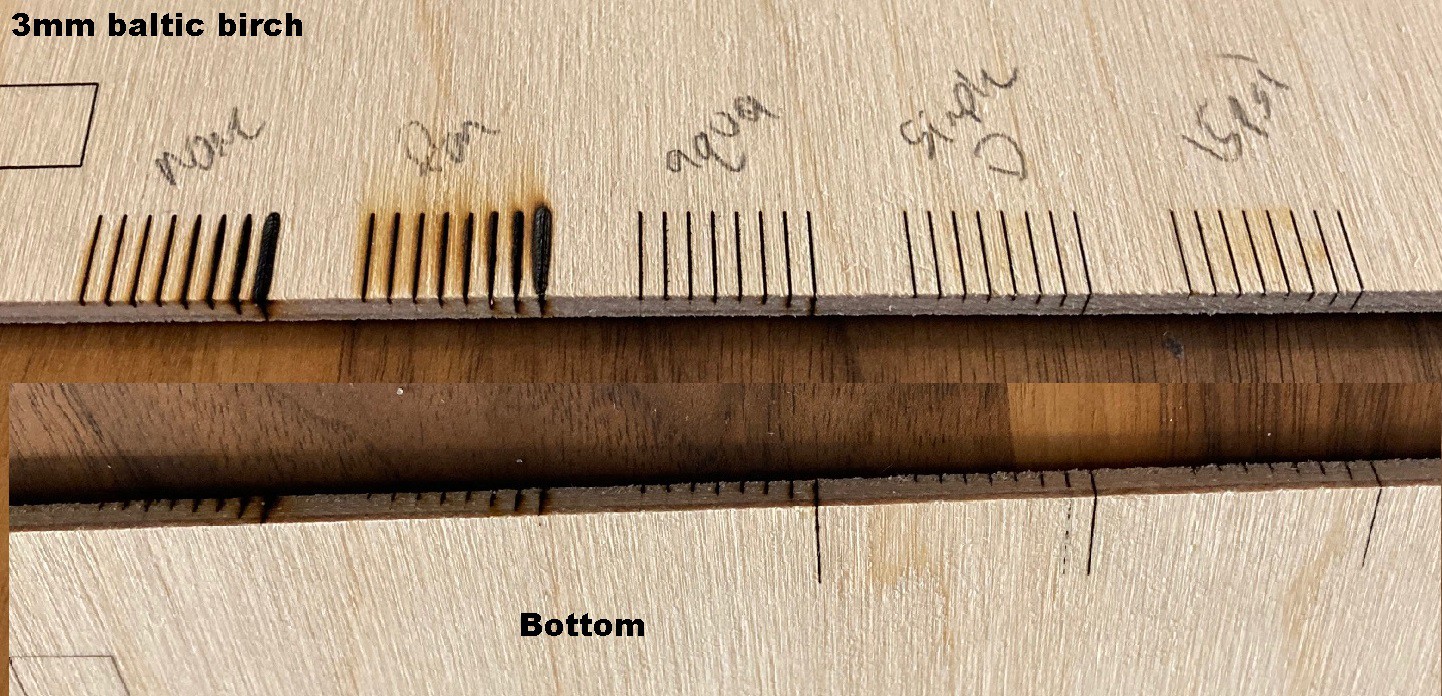

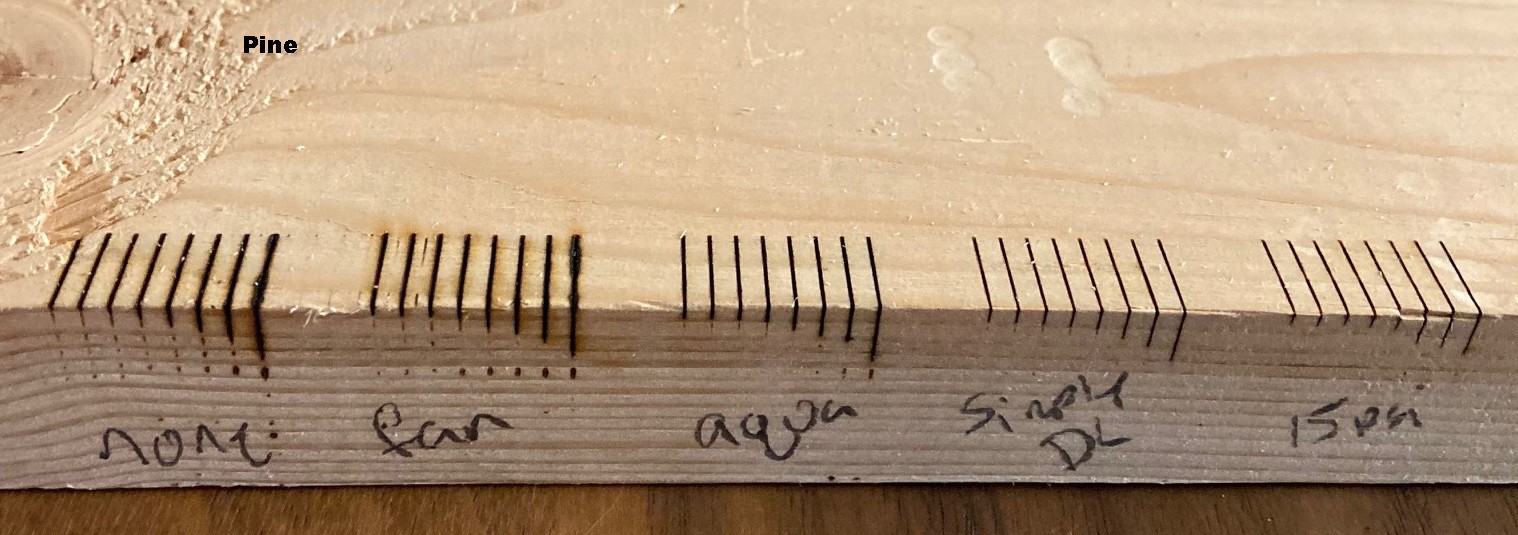

I was worried my previous test on MDF was not accurate, so I ran it again with some pine, 3mm Baltic birch plywood, and a broken bamboo cutting board. The surprising news is that the $15 Aqua Culture air pump is holding its own with these materials. I suspect this has to do with them being denser and therefore less flammable. My theory is that cardboard or paper would not fare as well with this low flow pump. That is another test I need to do someday.

I also need to slow things down even more to see if we can get more depth out of the cuts. And I need to quantify the speed tradeoff between going slower and deeper vs faster with more passes. I suspect there is a sweet spot hiding in there somewhere.

—

—

it has worried me that previously I saw a clear correlation between air pressure and cut depth yet none of these tests seem to show that.

I think there are two parts here. The new sealed nozzle is probably more efficient so the smaller pumps work better. And previously I was measuring near the front of the cut and this time I measured near the back. I think the laser was able to burn deeper near the front where the air was able to flow more easily. There is definitely a deepening of the cut near the front at least.

Again this could use more investigation.

David Tucker

David Tucker

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.