I'm trying to work out the best way to finish my spoiler board with some sort of hold down clamp. There seem to be a never ending number of ideas out there, but I think they all fall into three basic styles.

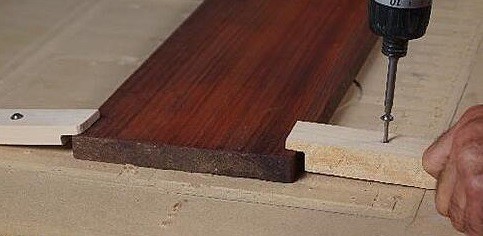

- Top clamp - Screws and clamps that press down on the top of the material, pressing it into the spoiler board. These are probably the most secure, they will hold the material even if the bit pulls up on the material. However since they stick above the work piece and cover part of the top you loose some material, and run the risk of the cutter and clamp coming into contact.

![]()

![]()

![]()

![]()

![]()

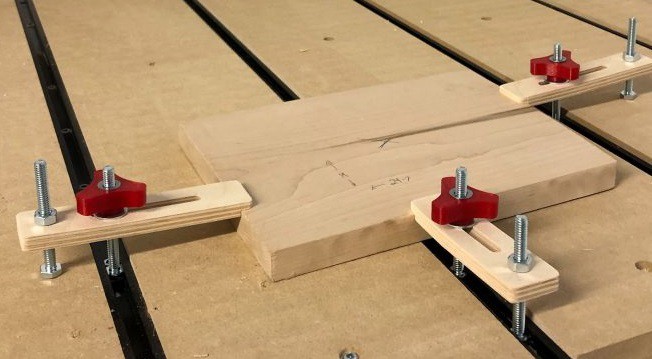

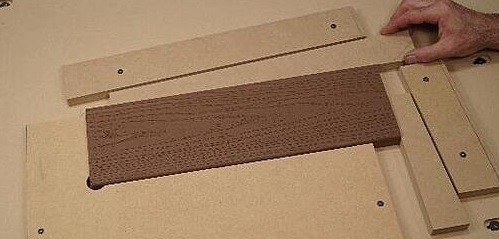

- Side clamp - These press against the side of the work piece like a vice. Typically these are fastened into the spoiler board and can be quickly removed and installed. They are not as strong as the top clamps and an up cut bit can cause the part to lift. However they are very convenient and popular and since they only engage at the sides you can use more material and potentially there is less chance of the cutter contacting the clamp.

![]()

![]()

![]()

![]()

![]()

- Bottom fixture - Using glue or tape of some sort to directly attach the material to the waste board. Typically this would be either double sided tape, or two pieces of painters tape that have been attached with some CA glue (krazy glue). The advantage of the painters tape is you can use a roller to press each piece of tape onto the material before affixing them to each other with the glue. In theory this holds things down better than just using double sided tape. The up side here is there is nothing to run into so you don't need to be careful when planning your paths, and the center of the part is glued down so you don't need tabs to hold parts that were cut out to the perimeter of the material. On the down side this is the weakest clamp, if you are not careful it can come apart. Also if the cutter goes through the tape it will gum up the cutter.

![]()

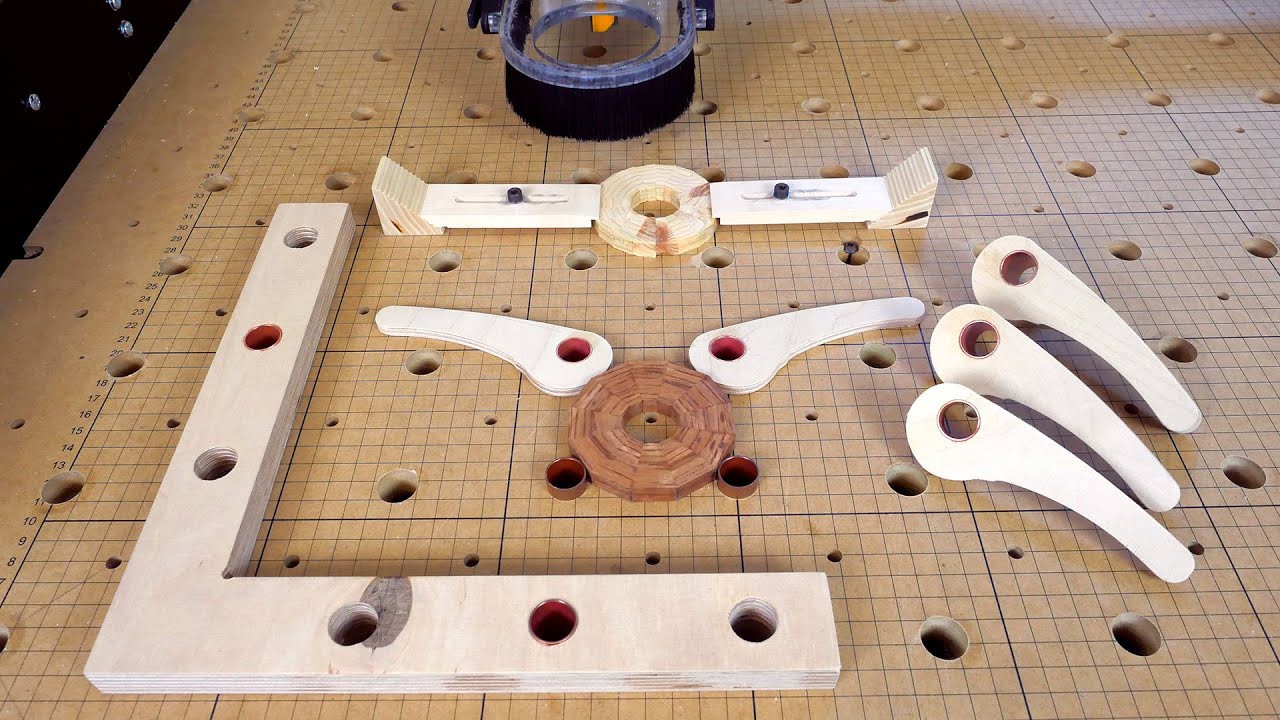

There are also many different ways to affix the clamps to the table.

- Screws - The simplest is to just screw the clamp (or part) directly into the spoiler board. This is easy and very strong, but it wears out the spoiler board over time.

- T-Nut - By drilling a hole through the spoiler board you can affix a 3 prong t-nut to the bottom of the board and then use a bolt to affix your clamps. The T-Nut must be inserted partially into the board so it limits how deep into the spoiler board you can cut safely, but if things go well this is relatively safe.

- Cam & Hole - You can drill holes through the spoiler board and then use some sort of a peg and cam setup to apply side force to the piece. This allows you to use the full spoiler board surface safely and it requires no extra mounting hardware. It is limited to side clamping only.

- T-Track - Using aluminum T-Tracks you can then use an inverted bolt to clamp parts to the track. This provides great adjustability in one direction but the nut tends to stick up fairly high above your work piece. Also the track must be securely mounted to the base or it can pull out. Some users cut T-Tracks directly into the spoiler board but this is a fairly weak solution.

Anyway that about sums it all up. I need to think of one or two of these to use on my setup...

David Tucker

David Tucker

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.