I wrote a new test to cut a series of lines on top of each other in the x direction while varying either the speed or power across the line. I used a 0.05 mm stepover in the y direction between lines, that works out to the equivalent of 2-4 passes over the same spot. That was too much of a stepover, I probably should be using 0.025 mm stepover since my kerf width is less than 0.1 mm

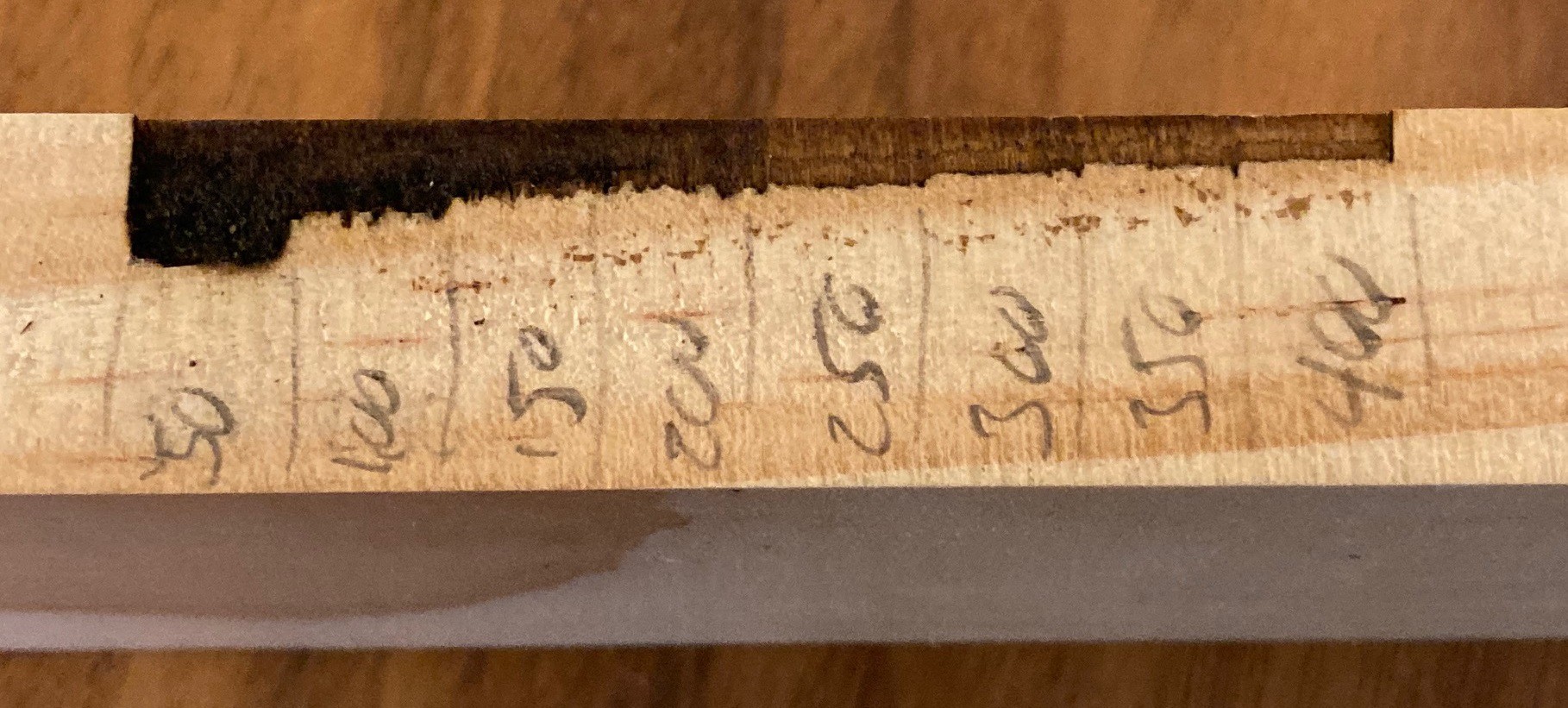

Here is the result when varying the speed from 50 to 400 mm/min in steps of 50 at 80% power with my NEJE N40630 module. You can see there is a lot of damage to the material when going at 50 mm/min, it is not super clear in this image but there is a lot of scorching on the wall of the cut. Things look much better at 100 mm/min and above about 200 mm/min the walls show very little damage at all.

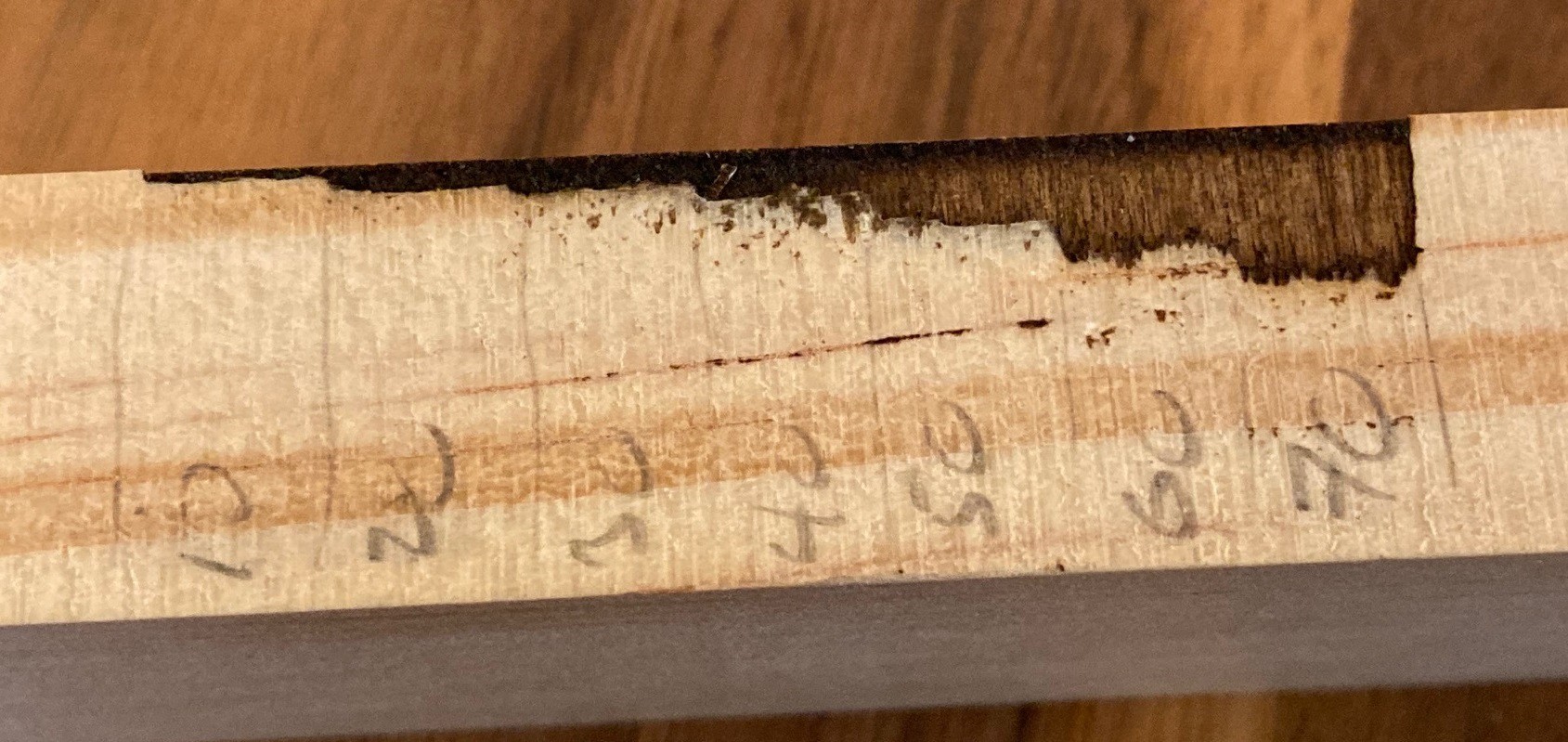

And here is another test where I varied the power from 10% to 70% in steps of 10 at 100 mm/min. At around 50% power we start to see significant damage to the walls, although not nearly as bad as 50 mm/min at 80% power. A bug in my test code prevented this from going to 80% so we can't directly compare it to the last test. However at 70% power and 100 mm/min we are cutting deeper than the test at 80% power and 100 mm/min on the previous test. I suspect this is because the wood is not very uniform and I hit a softer spot.

If you look close at both pictures when the cut is the deepest you will see that there is a lot of variability to the cut depth. I measure it at around a mm of variation.

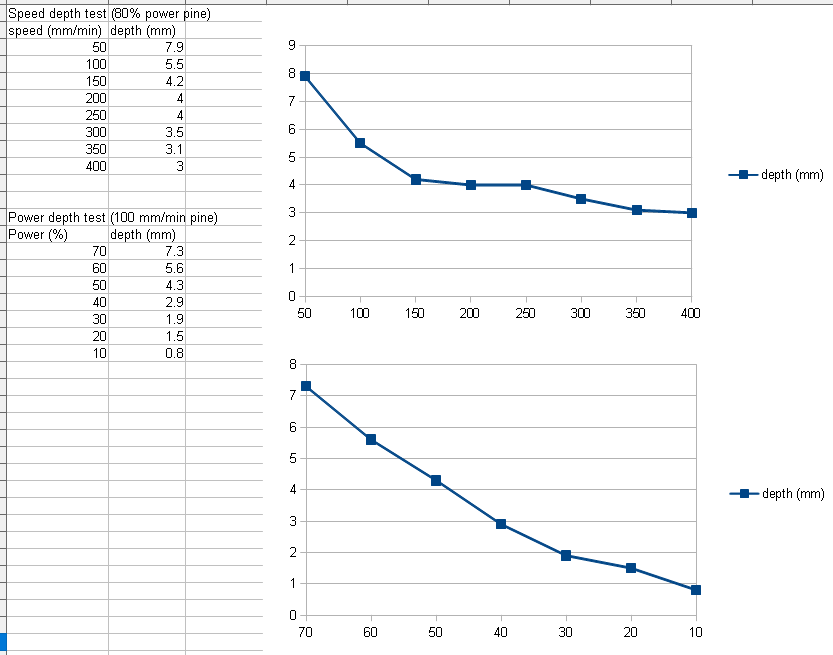

I roughly measured the depth of each cut, these are probably accurate to within a mm, and then plotted out both in the above graphs. You can see that there is a clear logarithmic (1/x) behavior when we vary the speed while varying the power has a much more linear behavior. It was difficult to measure the shallow cuts with any accuracy, this is probably more linear than it appears.

If you combine all this data together with the images above you can see that while we can cut material up to 7-8 mm deep with enough passes and a very slow speed we are probably better off running at 150 mm/min or faster and sticking to depths less than 4 mm to both optimize cut times and to get the best surface finish.

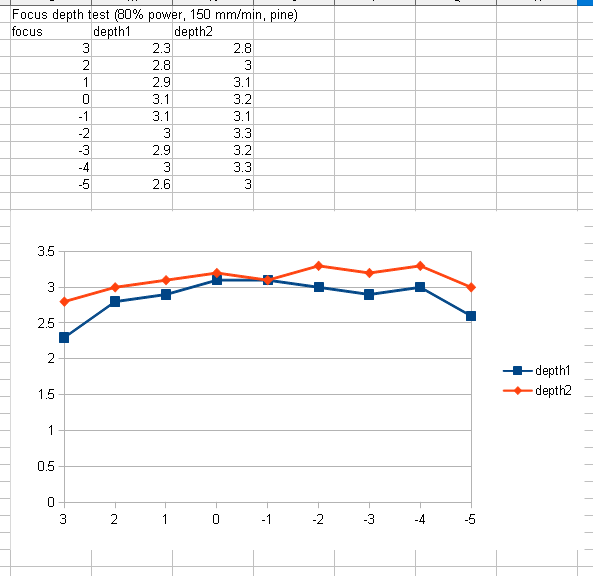

Finally I ran another focus test where I started 3 mm higher than focusing the laser on the surface and lowered it on each line to 5 mm below the surface. I first used my new microscope to verify that the laser spot was in fact focused on the surface of the pine. I measured the cut depth twice using my usual trick with a feeler gauge and calipers. The results came out almost 0.3 mm deeper the second time. My theory is that there is a lot of ash at the bottom of the cut and each time I insert the feeler gauge it cuts deeper into the ash. This variance makes it very difficult to measure anything to better than 1 mm accuracy.

Anyway looking at this I don't see much variance in the cut depth. I have a feeling I need a much wider range to truly see the effects on height. It looks like getting focus dialed in to within 6 mm (on this piece of pine) gets you a reasonable depth of cut. Next I need to do a ramp test and work out if it is resulting in a value that focuses at the surface of the material or deeper. Finally I can try re-running my previous test to see if lowering the laser between cuts has any value. It is very possible that in the past I was focusing well below the surface on accident and lowering the laser further had a negative impact on the depth of cut.

---

If you look closely at the cuts above you can see a definite darkening of the burn where the darker tree rings are. That throws any results off just a bit. I'm still working to find a more optimal material to run these tests on. I would like something that is extremely uniform in every regard. I may start looking at cutting foam or plastics that are more uniform.

David Tucker

David Tucker

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.