So after the last post looking at expensive filters I decided to go in the opposite direction and see what I could do with the tools I have.

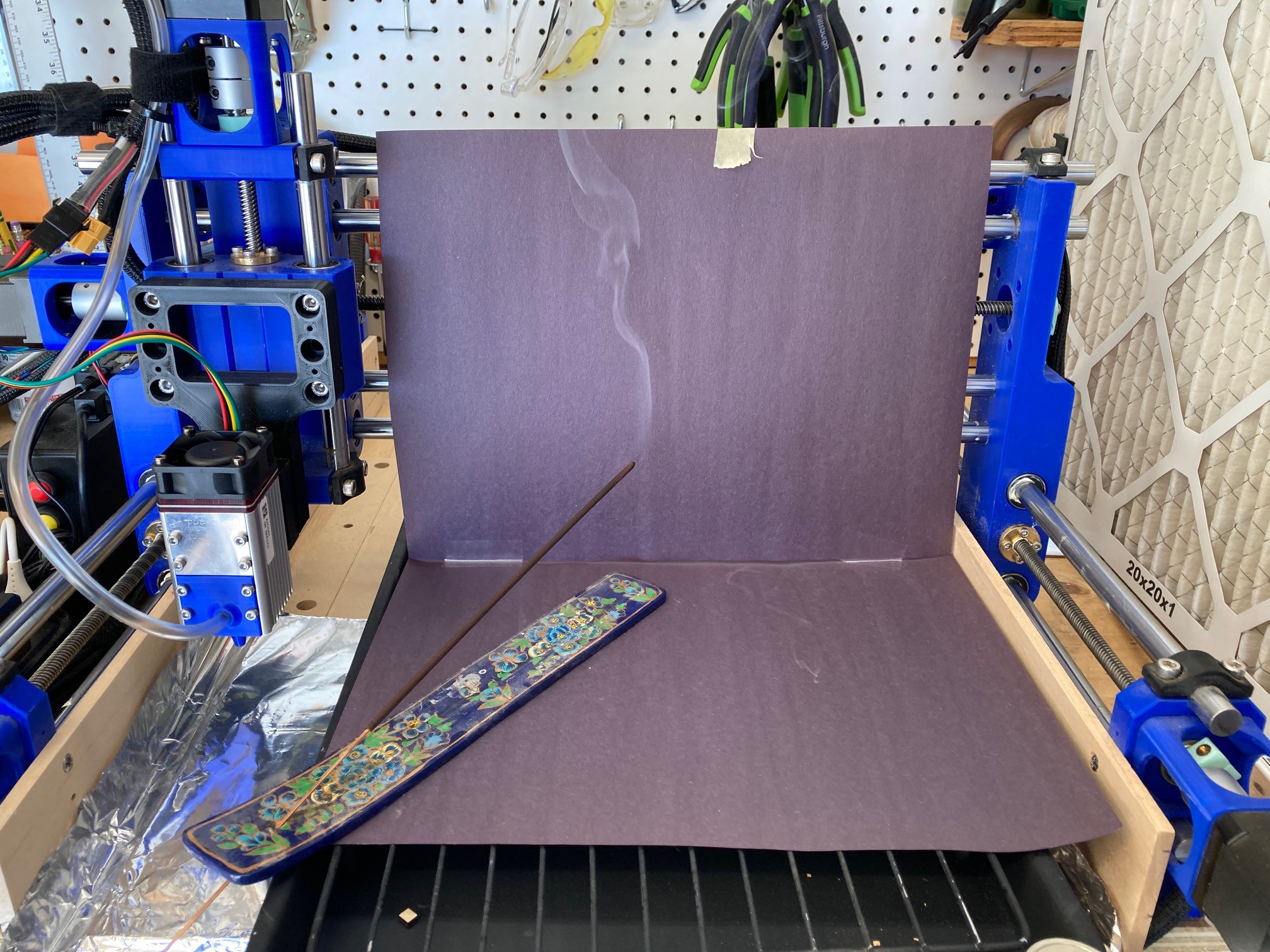

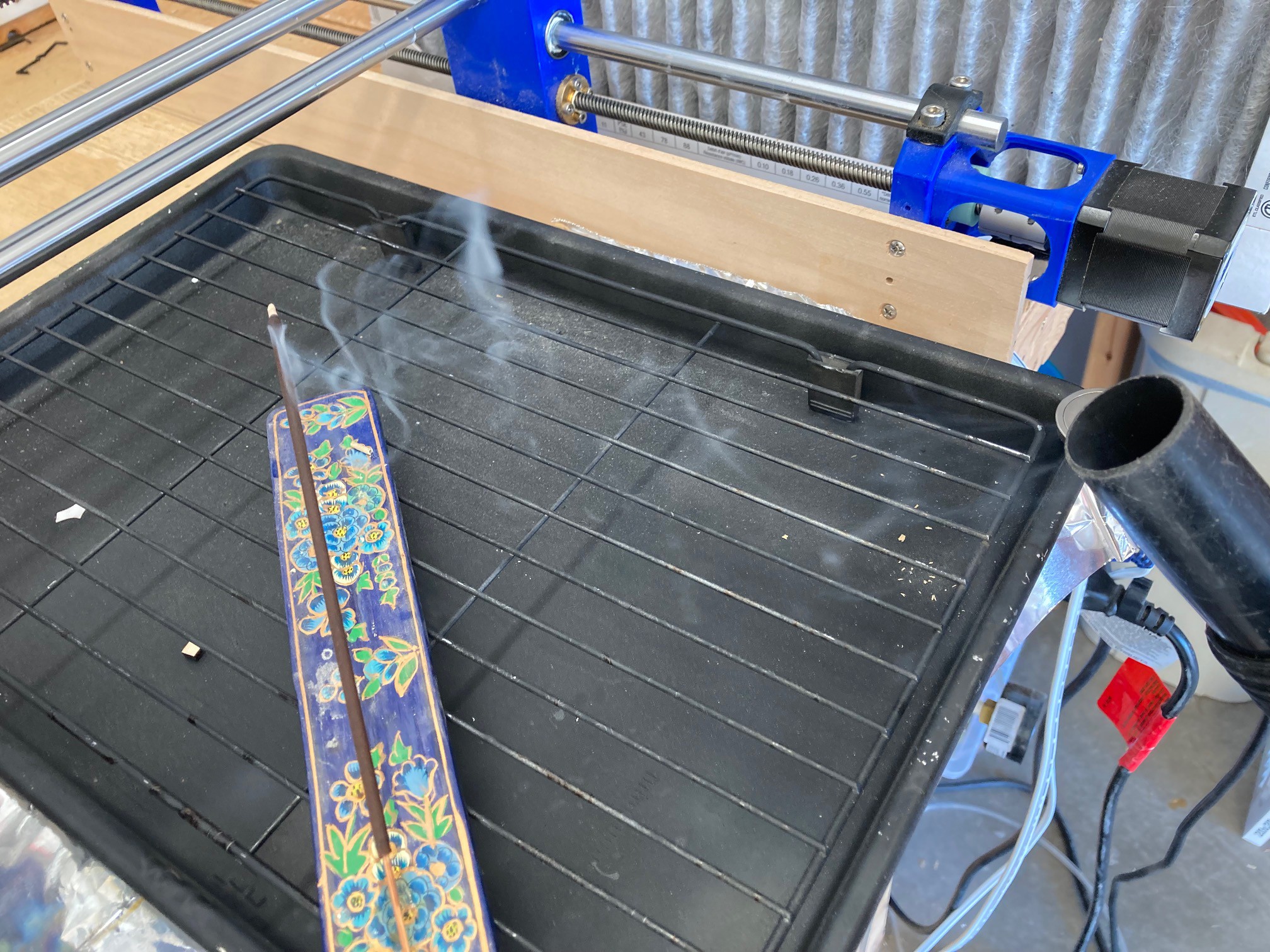

To better visualize things I borrowed an incense stick from my daughter to make a little controlled smoke. Here it is burning without any air flowing at all. I initially tried putting a black piece of paper behind the incense to make the smoke stand out. Later I tried it without the paper but I did not document things.

Here it is again with the fan running on high. The majority of the smoke is going into my fan but I can still smell the incense on the back side of the fan so it is not filtering out all the smoke or some is passing around the fan.

I have had this 'charcoal' filter laying in wait for my current filter to finally get clogged up. It has charcoal pellets glued to it but there are large gaps between the pellets. The air flow seems quite reduced with this filter in place and the smell test does not seem to show any improvement. I will try to give it a proper test, but I suspect this is more hype than reality. To really work you would need many layers of charcoal for the air to flow past to ensure every particle had a chance to come into contact with the pellets.

I spent some time moving my box fan around the machine to see if there was a better plaice to position it. It turns out the best place is 4" from the laser head. You may be able to make things work better by adding in baffles or enclosing everything in a box, but the closer the better.

Finally I tried using my shop-vac, you can see at about a foot away the smoke is vaguely getting pulled into the nozzle.

At about 6" away it appears that all the smoke is going into the nozzle, but it is still slow.

At about 3" the air is moving very fast and all the smoke is flowing into the shop-vac. This is a very strong fan, probably much stronger than we need for a diode laser cutter, especially if we can mount the intake close to the laser itself.

Using a shop-vac as an air filter may not be the best idea. On more powerful lasers you can get a large buildup of gasses that can catch fire. The above video shows this happening a lot when cutting plexiglass. Our smaller laser is not as powerful and probably won't generate as much gas but if you use the shop-vac for collecting sawdust you may run the risk of starting a fire in your shop-vac. If you used separate hoses and filters for wood and smoke this may not be that great of a risk. A clean shop-vac should be close (in principle) to a laser air filter so there is no inherent risk other than leftover contaminants.

The shop-vac is loud, and I have not been able to find any charcoal filters for it, so it is not the best solution. However there is an outlet on the shop-vac and you could add a charcoal filter there or run a vent hose out of the work area.

Another idea is to focus on the smoke at our face and use a respirator with 3M 2097 filters with 'nuisance level' organic filters. These look like small filters but you only bring in a small amount of air (relatively) every breath. This is not as good as a proper charcoal filter but it should help out quite a bit. There are larger cartridge filters that include a lot of charcoal that you could also get for a little more money. These are more difficult to breath through, but they would also be safer.

Finally we could just run a hose out the door and put a small inline fan on it.

Nothing says we can't combine these together. It is probably a good idea to wear the respirator anyway, and venting filtered air outside is a good strategy, as is opening the garage door.

David Tucker

David Tucker

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.