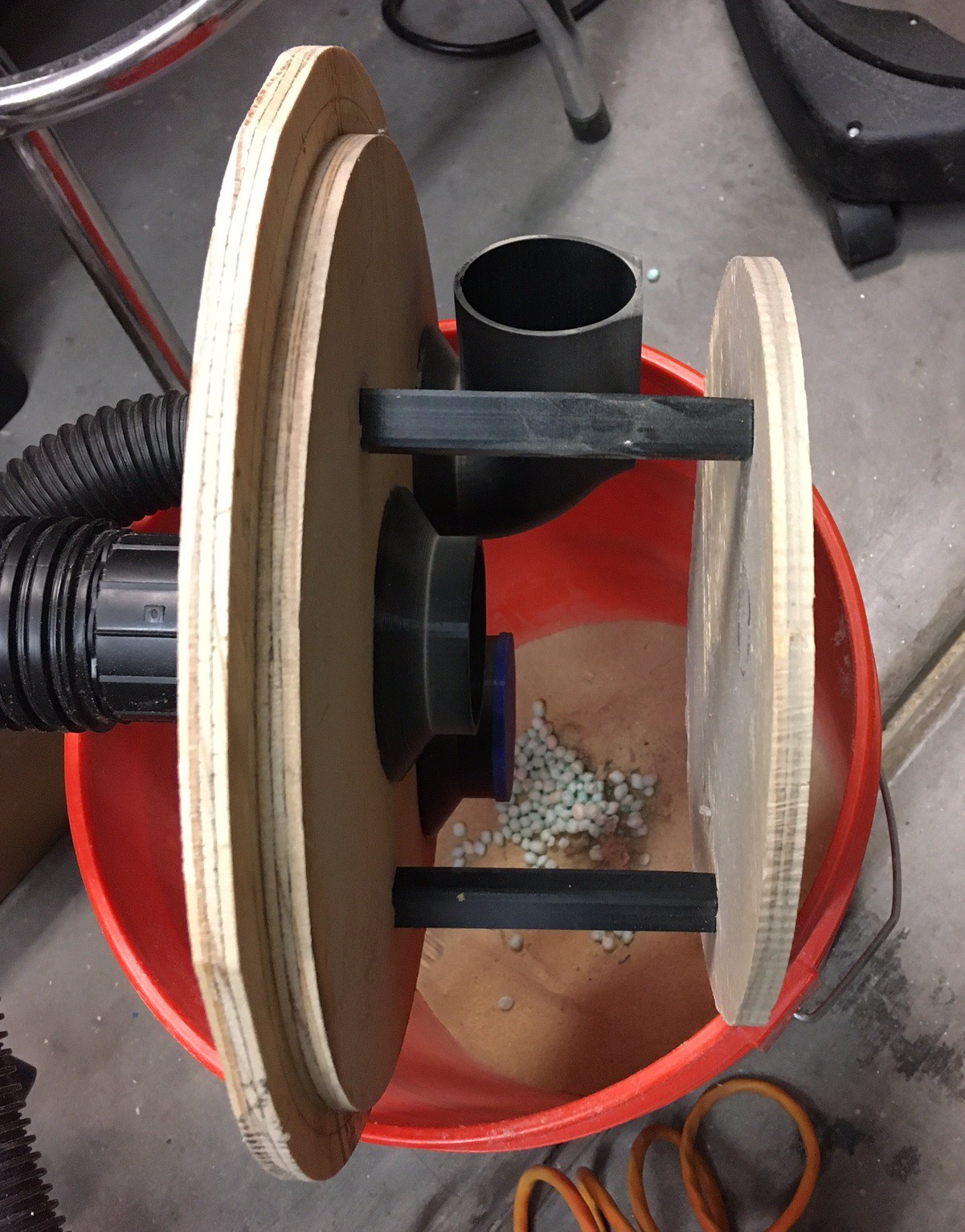

Ok I cut a 22 cm diameter disk and used it in place of the Thien baffle and that seems to work just as well. At least with only 2" of dust in the bottom of my separator. I will need to wait on more dust before I can evaluate if the lip is really needed or not. For now I'm going to leave the disk in place and leave the dust bag off my shop vac so I can better evaluate this over the long term.

So for now the final design is 3 rings of 1/4" plywood at 33 cm, 28.5 cm and 22 cm. Glue the top two together and use 10 cm standoffs for the baffle. It seems to be working well, with only a bit of dust making it through to the shop vac. I'm also dropping the diffuser for now, it does not seem to help much and it is easy to plug up.

The wood lid and Thien baffle are not needed but they do make things nicer to deal with and have some benefits to the strength and dust collection. I think the vacuum release valve is the big win, it saves the shop-vac motor when you get a plug and stops the system from getting stressed. I'm surprised there is not one built into the vacuum.

On a side note my 1-1/4" shop-vac hose is really not up to the job. It clogs on the smallest pieces and overall is just a real pain. On the other hand most of my tools don't need a 2" hose, and it was free with the vacuum. Eventually I should break down and pick up a 1-7/8" hose, it would probably be a better compromise between suction, flexibility and clogging.

David Tucker

David Tucker

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.