I have my laser wired up and running now with full control over power in GRBL. So far I have been able to slice up a few sheets of paper and burn some wood. I have not tried cutting wood yet.

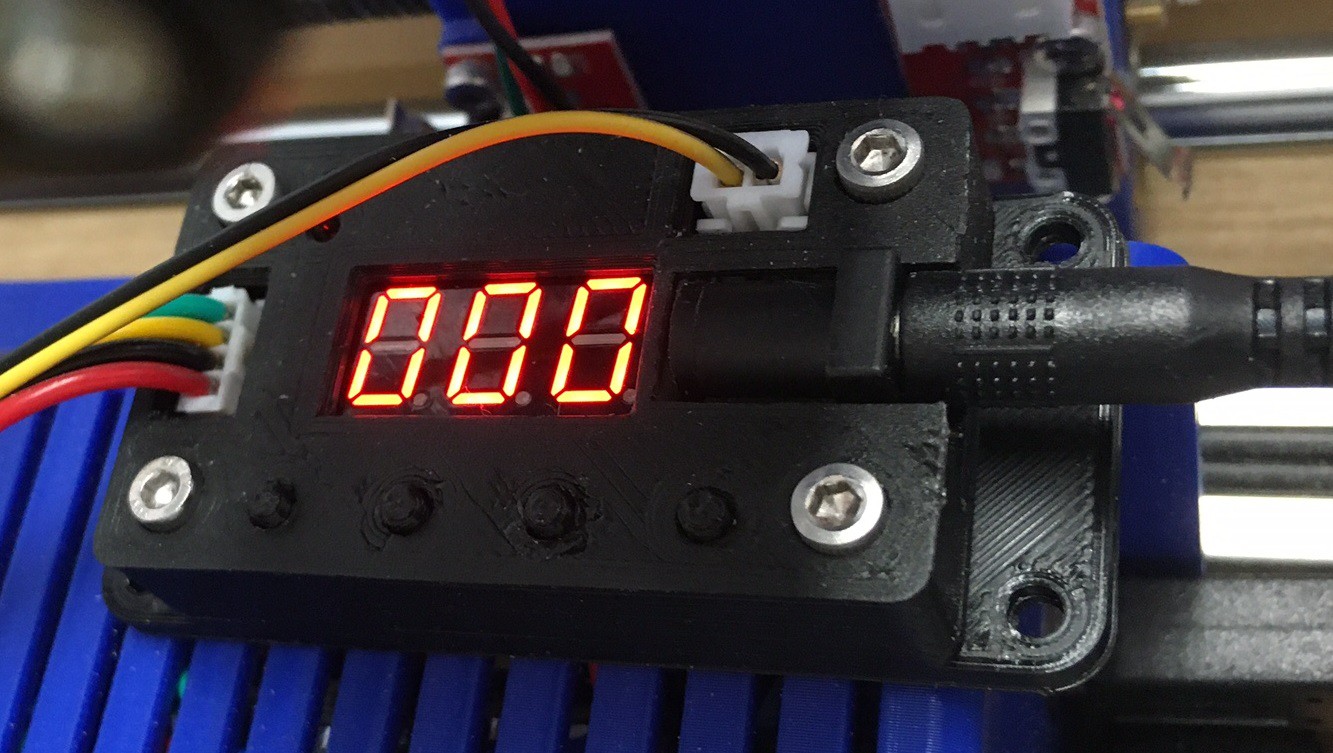

I went ahead and used the NEJE PWM/Temp module to act as an intermediary between the laser and GRBL. It is not needed but it has a few nice features. First it can read out the temp of the laser module and display it at the push of a button, even while the laser is running. It can also be used to manually drive the laser for focusing. It also displays the requested laser power when under GRBL control, that acts as a nice double check so I can see if GRBL is doing the right thing. Finally it has an on/off button so you are less likely to accidentally trigger the laser when your not ready for it.

I printed out a nice housing for the module so it is not quite so sketchy.

I'm just getting started but here are some observations so far

- This laser produces smoke, but less than I was picturing. Still it is enough that it is no fun to breath and it can give you a headache. I would say it is less smoke than an incense stick. Still it is not nice smoke, it is enough that I will be getting carbon filters for my respirator and working on a proper air filtration system for the shop.

- It takes only a tiny amount of air to blow out the flame and smoke produced by the laser. I experimented with different levels of air using a compressed air duster and even the smallest trickle I could produce was good enough. This explains why fish pumps are so popular.

- The glasses mess up your vision, they very effectively block all blue and green light and after wearing them for an hour your eyes become overly sensitive to those colors making you feel off. It takes a half hour for this to go away afterwards. You probably get a similar effect from tinted sun glasses.

- It is hard to dial down the power on this 30W module, on top of that GRBL is only capable of 256 levels of PWM. I found that for MDF above about 20% power just burns the wood, and below 5% power has little effect on the wood so you only have around 40 shades of grey that you could produce at best. In practice you are probably limited to something closer to 15 shades if you dial your power in just right. The spot is definitely rectangular as well and relatively large. I'm seriously considering picking up the 2W module as well to do engraving. It is only $30 if you don't get any accessories, and in theory it should fit the same mounting bracket and use the same wires.

- The controll software side of things is not great:

- I really love Universal GCode Sender but it does not officially have a laser mode. If you could produce gcode from another tool you could still use UGS to control the machine but that sounds complicated.

- LaserWeb is screwy, I could not make any progress with it.

- LaserGRBL is nice but it has quirks. For example you have to tweak the image as you import it, once you bring it in there is no going back and editing the line spacing or speeds. There is no real layout mode, you import the image, trim it and that is it. Its jog mode is not perfect either. On the upside it is free, and fairly functional as long as your working with an image that was already processed in another program.

- LightBurn is reasonably priced at $40, much better than the several hundred dollars needed to get VCarve working on the milling side. It has very strong page layout tools and some ability to convert images to vectors and edit them. With that said it is no as intuitive to edit with as Inkscape or Illustrator, but if your doing something fast it works. On the down side the GRBL support is confusing. Jogging is horrible, and there is a lot of confusion in my head about where the origin is. No matter how I set things up it seems to shoot off in a different random direction every time I start a job. Also the laser power seems to be running at 1/3 what it should be. Anyway it has potential but it is a bit overwhelming and confusing to start with. I will need to spend some serious time with it before my demo runs out.

- Safety wise this feels better than I thought it would. Having the fixed bed and everything mounted solid helps a lot. It is still hard to remember to reach for the safety goggles and to not take them off ever. A fully enclosed case is a much better idea for sure.

David Tucker

David Tucker

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.