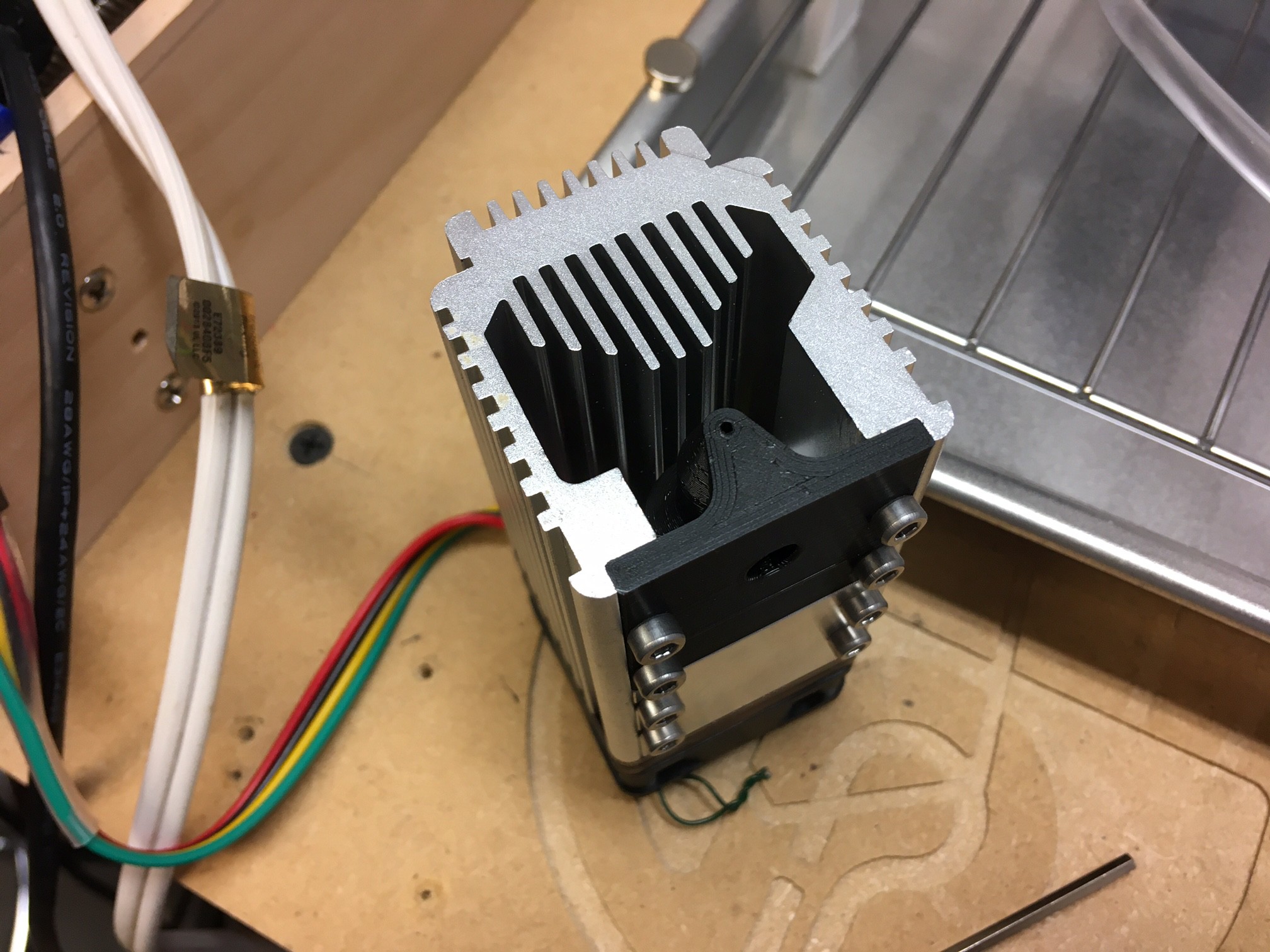

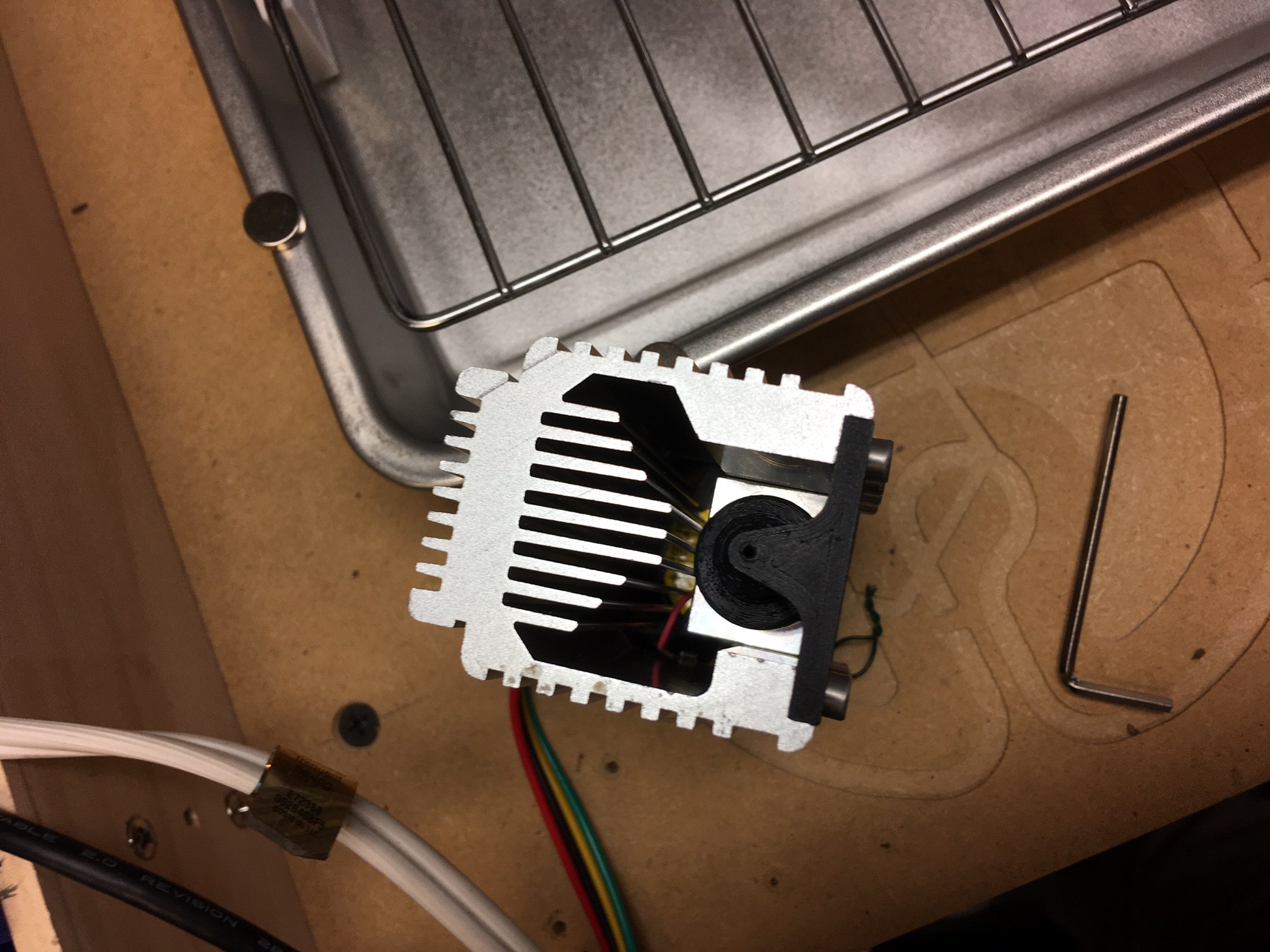

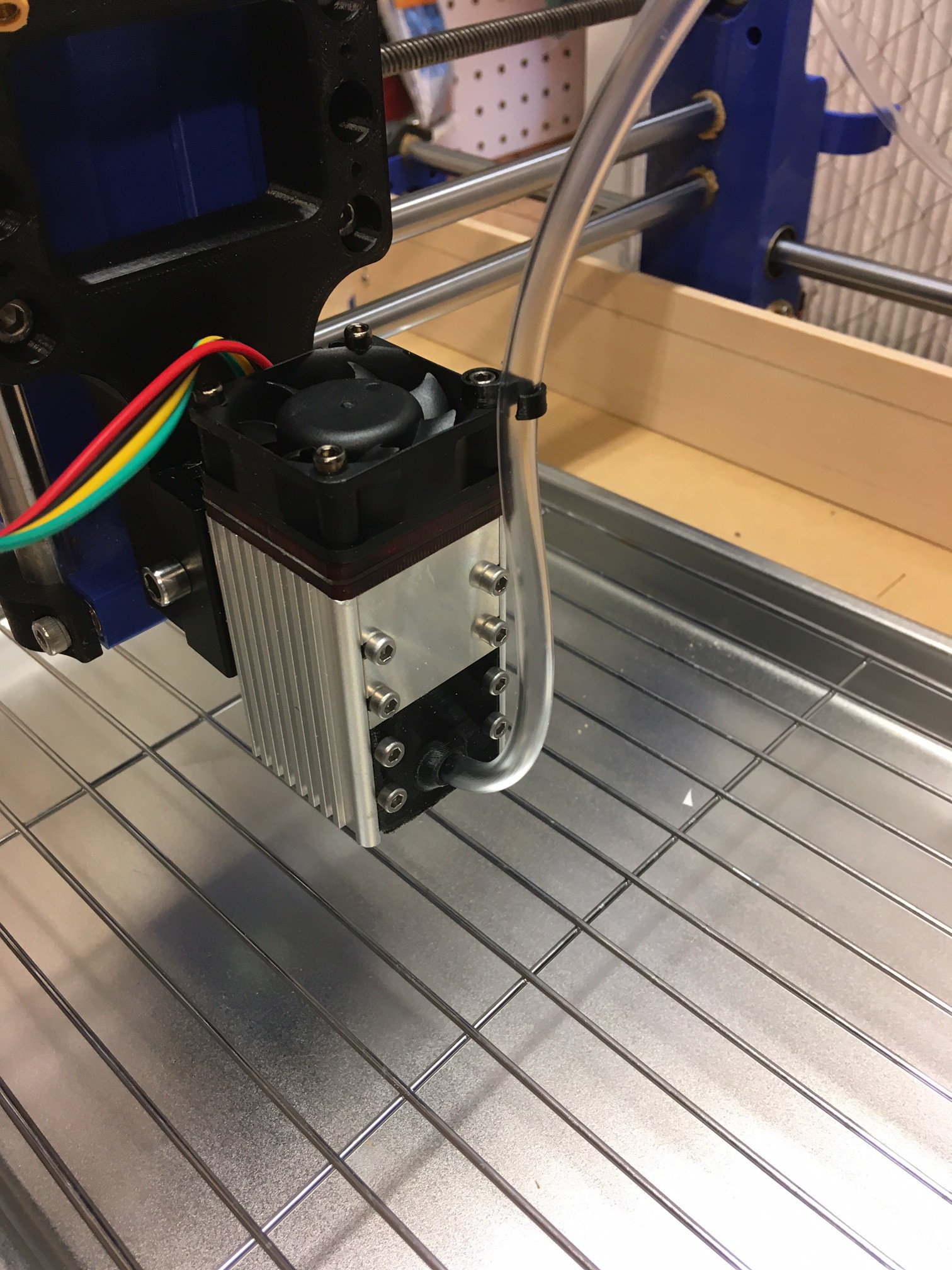

A while ago I made an air nozzle for my laser. This replaced the red shield on the front of the laser and completely enveloped the lens so the air is flowing in the exact same direction as the beam. This worked really well except for one issue, more air leaked around the lens than came out of the nozzle. I could try to seal things up at the lens side of things but I worry that is just going to make a mess and be difficult to reattach when servicing the laser.

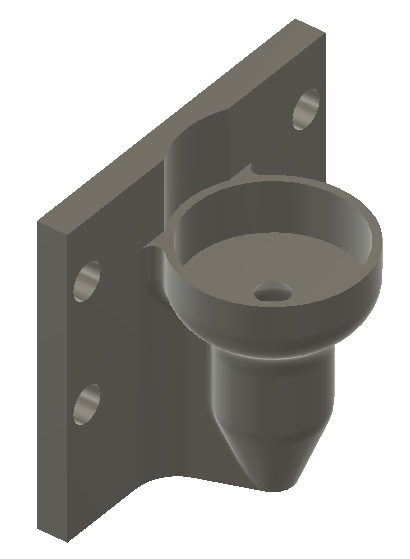

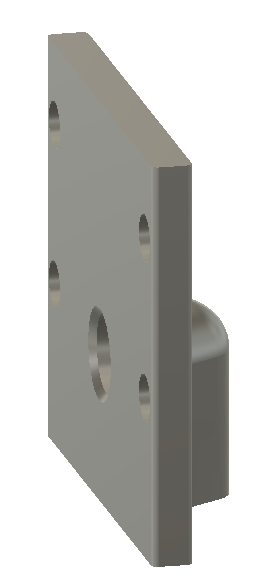

So I decided to redesign this again using a nozzle that runs close to the beam but not quite in the same direction. This is not as good air wise but hopefully it will help keep my compressor from cycling so often and should allow me to use more pressure. It is not clear in the rendering but the nozzle has a bit of an angle to it internally, that seems to be just enough to push the center of the jet over the center of the cut at a distance of 5mm from the end of the housing.

At the same time I made a series of test nozzles with various size holes in them to see how the size affects the air flow. I printed sizes from 0.5mm to 3mm in 0.5mm steps and found that the 2 and 2.5 mm holes produced the best results. At 3mm the air flow was spread out too much and unfocussed, and at 1 mm it was severely restricted with much lower flow and pressure, 1.5 mm was ok, but 2mm had a detectably stronger flow.

David Tucker

David Tucker

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.