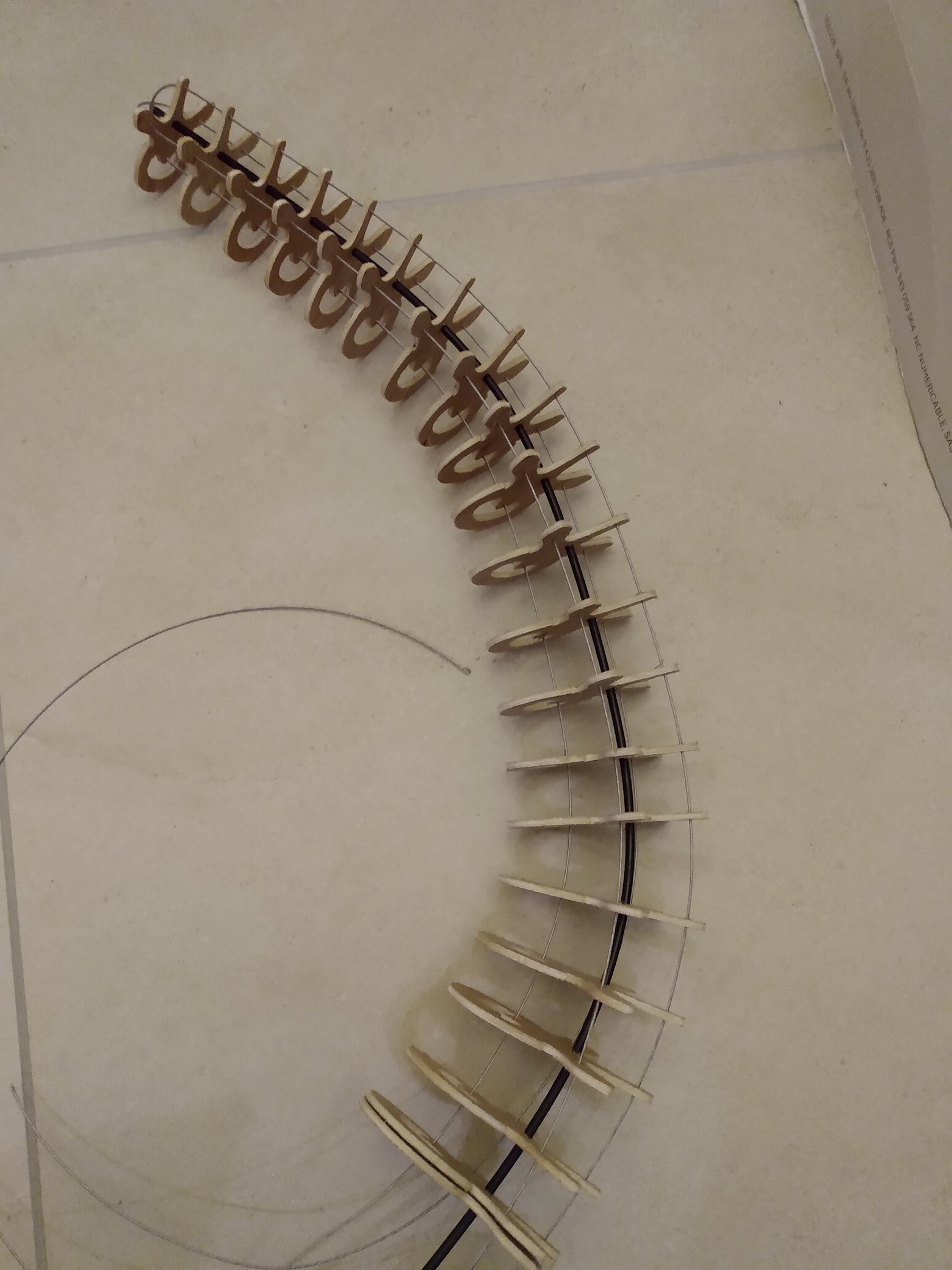

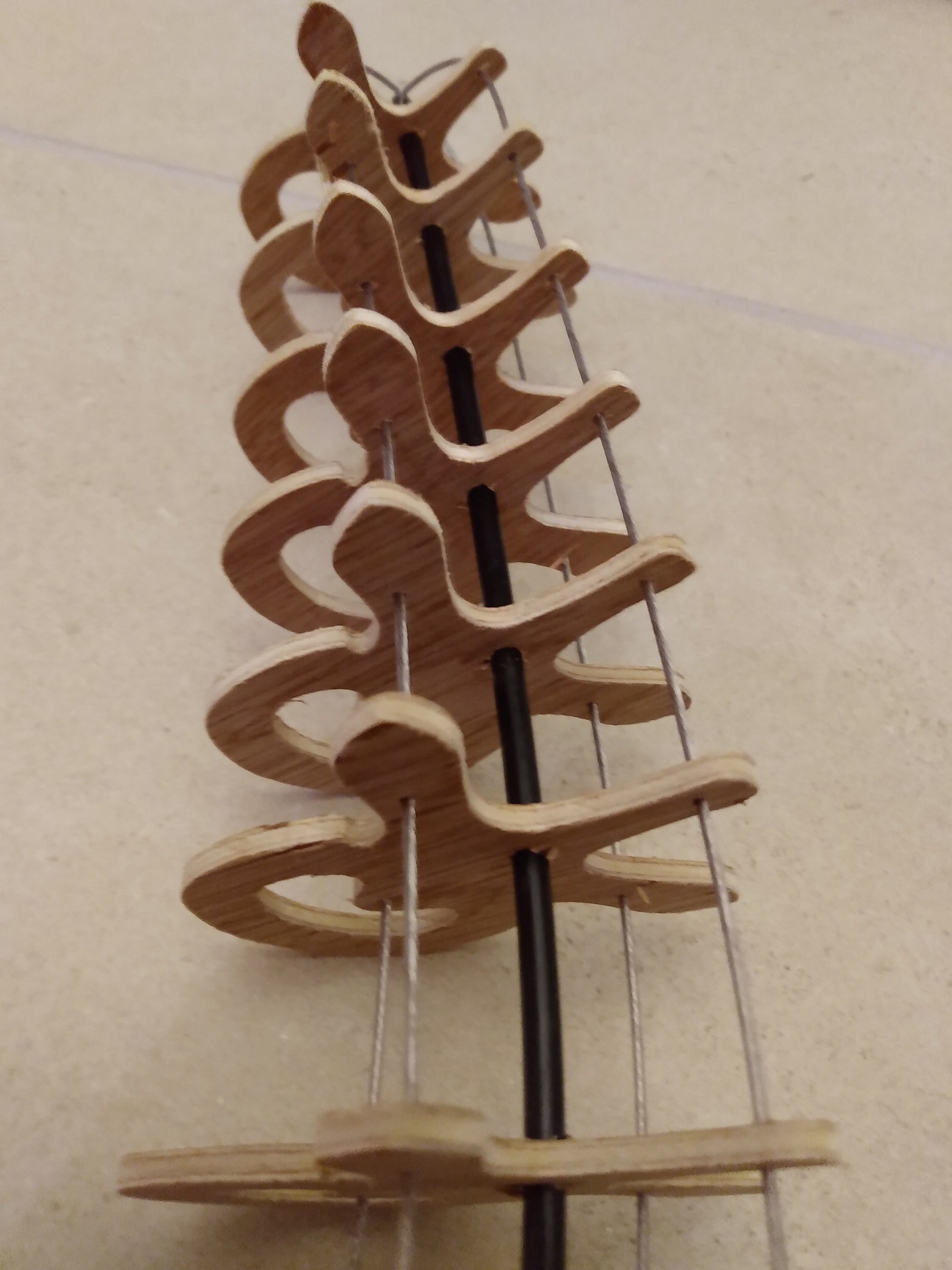

I managed to cut 21 profiles ( in 4 runs on the cnc ) and i couldn't help but try a dry fit with what i had on my hands :) :

the only problem was that i had to re-drill every hole to make the bike shifter cable go though... I also understood why my plywood started to fell off : there is only a micron thick layer glued on every side! I though plywood was made of equally thick layers but this one is plated :( .

the only problem was that i had to re-drill every hole to make the bike shifter cable go though... I also understood why my plywood started to fell off : there is only a micron thick layer glued on every side! I though plywood was made of equally thick layers but this one is plated :( .

i used steel fishing line (rated 63kg, coated in plastic) for the actuation cables it looks lightweight and works well.

i used steel fishing line (rated 63kg, coated in plastic) for the actuation cables it looks lightweight and works well.

However i'm wondering how i will turn this bendy, twisty contraption into a sturdy lamp: i expect to have at least a lateral rigidity so i can actuate it only longitudinally . I'm still missing some spacer in between and maybe i will have to glue them to avoid torsion. I'm also thinking of replacing the lateral cables by some thin piano wire to straighten/rigidify . The assembly also suffers from the fact that the bike cable looks permanently bent in some places despite me trying to straighten it with some weight...

I don't know if it will make a great lamp but it is a really fun thing to build !

I don't know if it will make a great lamp but it is a really fun thing to build ! The movements looks really organic:

I will look into what i can do to improve the movements predictability but for now i'm really happy on how it came out !

I will look into what i can do to improve the movements predictability but for now i'm really happy on how it came out !

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.