After taking the dust for a while, i restarted the project:

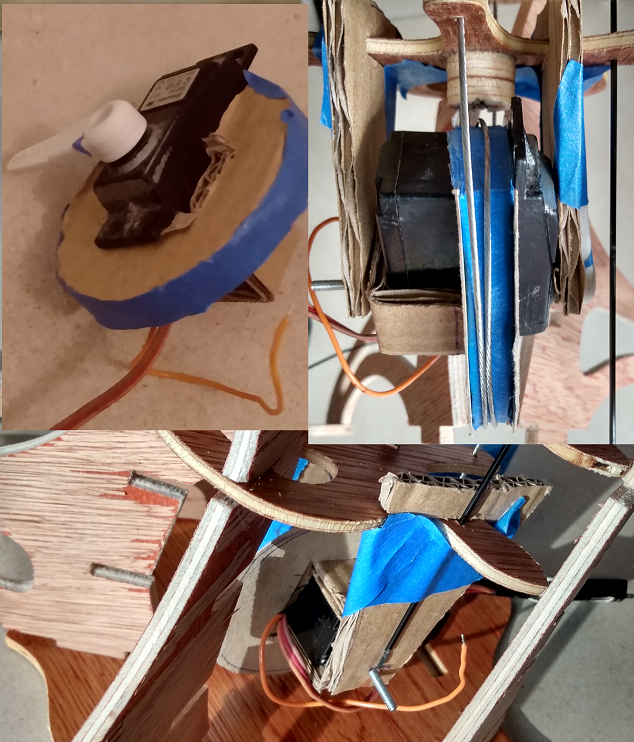

i knew the stepper was way too weak to animate the arm so i decided to use an old standard servo that i had laying around.

To test the idea, i went through a cardboard prototype again:

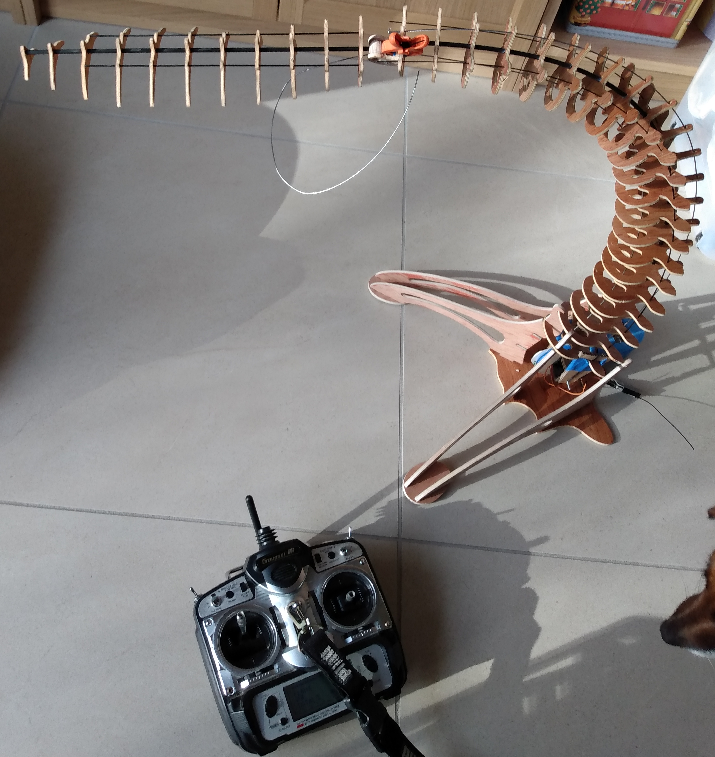

Tested the setup with my RC transmitter:

Tested the setup with my RC transmitter:

The servo managed to move the arm back and forth with sufficient torque !

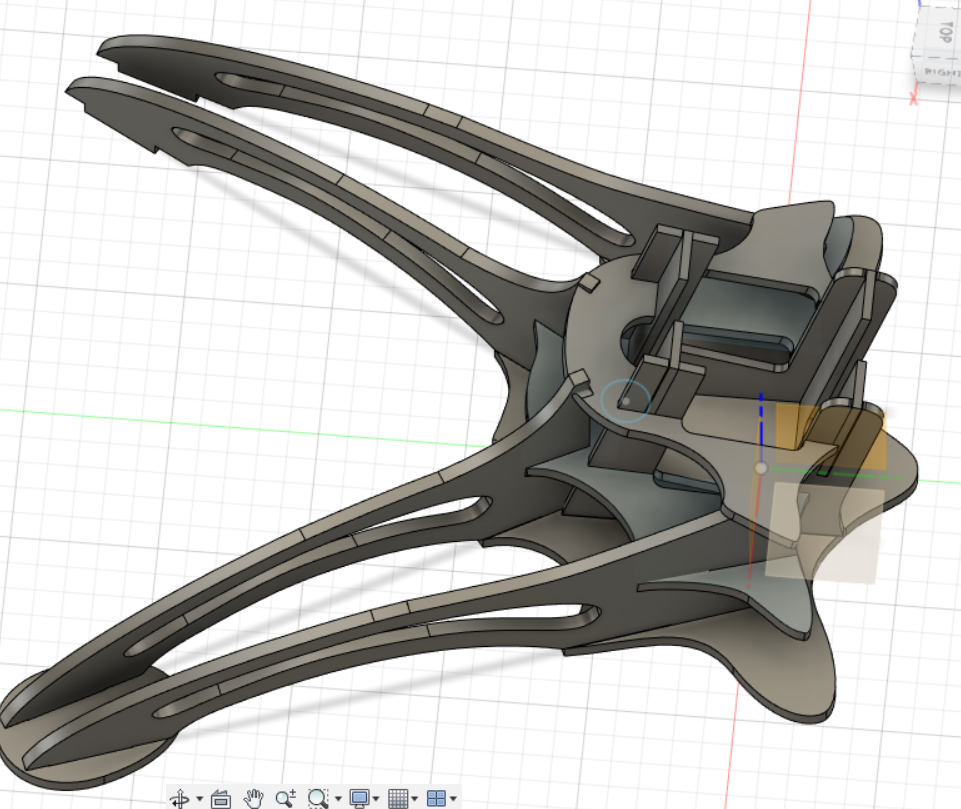

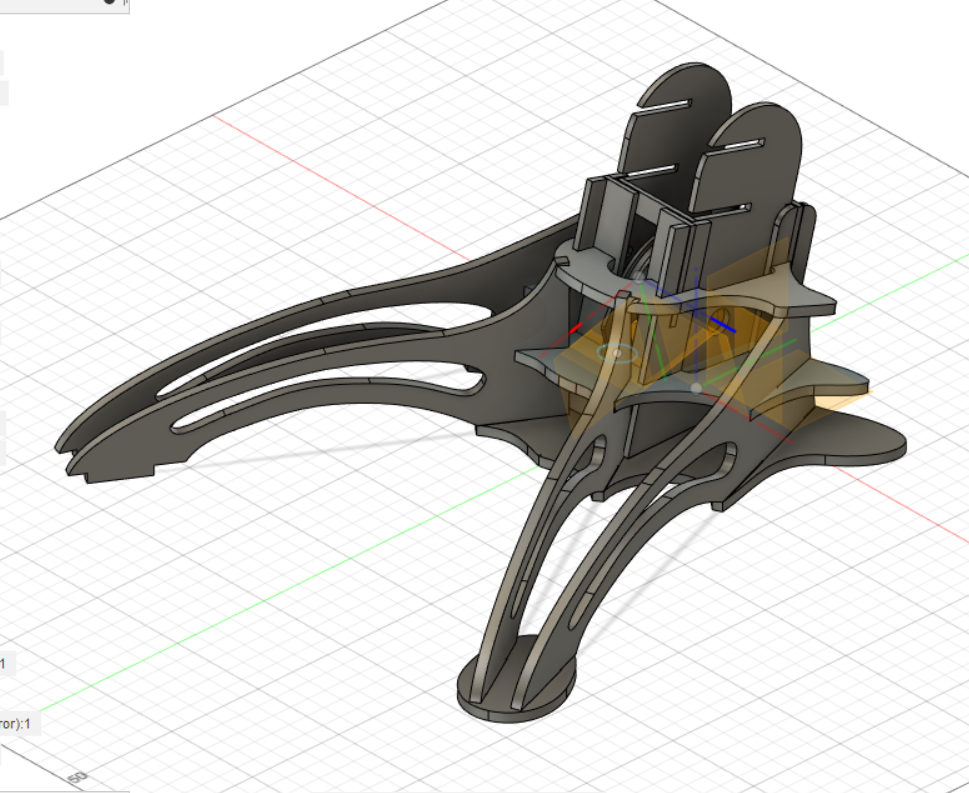

So i moved on with the design in fusion 360 and cut the support

Once in place in the lamp base, this plywood support did its job as expected, compared to the cardboard prototype, it did a better job at articulating this arm. However, i realised that i did not had any way of servicing the servo if anything when wrong with it : i had planned to glue everything in place with the lateral "feet" but the assembly was questionable. Back to the drawing board...

This is when i had this long pause in the project because i ran out of ideas...

I managed to get back to it by learning new skills in fusion 360 and putting blender aside :

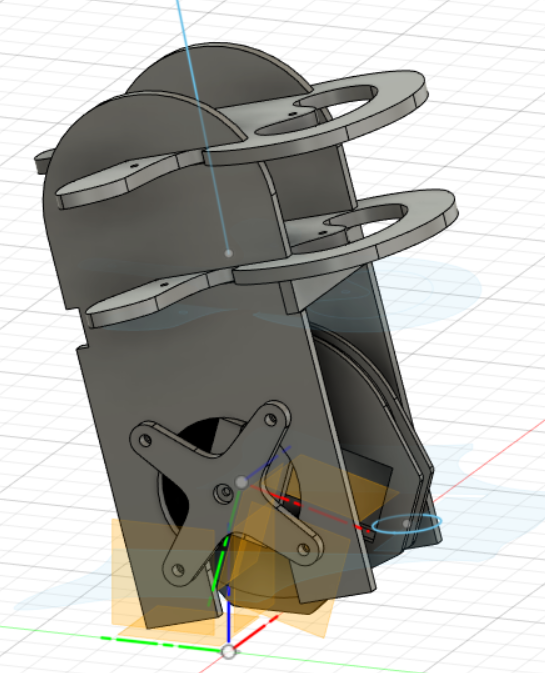

i redesigned the base around a rectangular core (just like skyscrapers) where the arm would slide into place.

The base of the arm would contain the rotary servo assembly that is now secured by four screws

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.