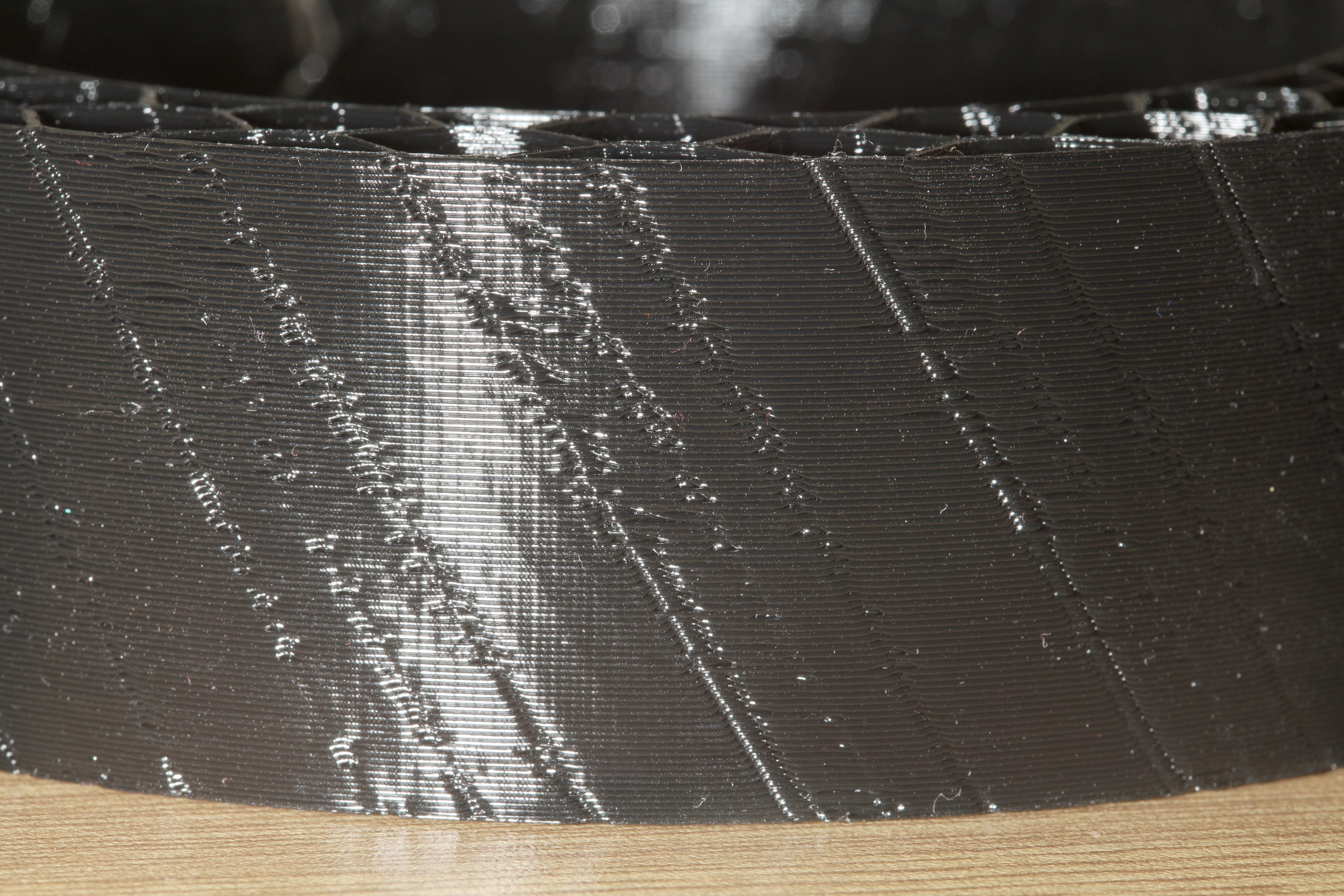

The last tire was real fragged.

So along came another one at 230C, with a 1.6mm tread. It still had voids. Some guys leave their filament on an enclosed print bed for 5 hours. Another thing which might improve layer adhesion is breaking up the smooth tread with slight ridges. A smooth tread still has the best traction with TPU.

As rough as printed tires are, it pays to remember what lions did before 3D printing. Those were desperate times.

lion mclionhead

lion mclionhead

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.