Sorting proces

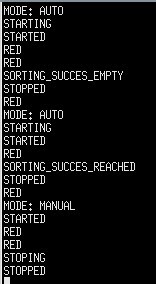

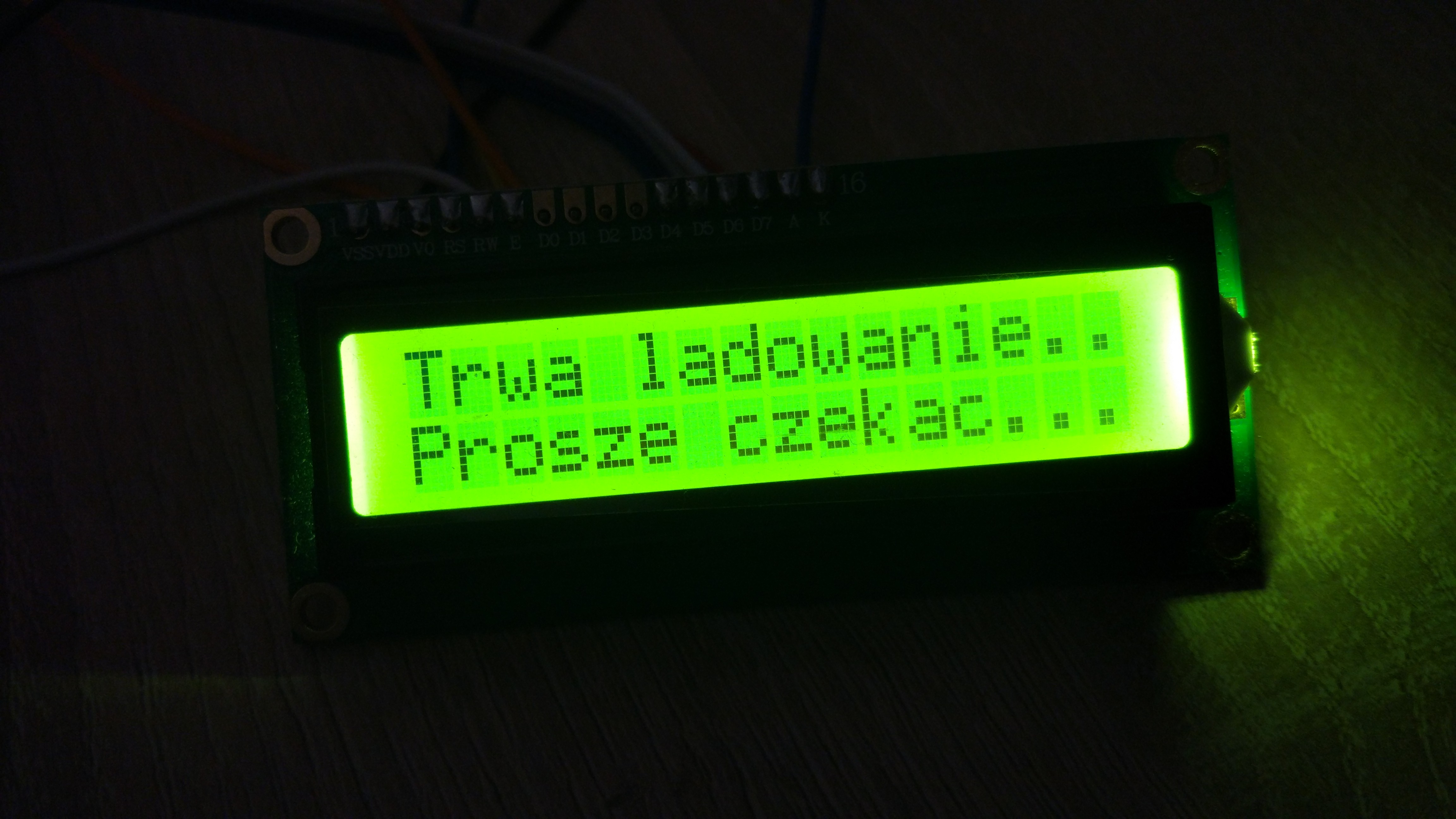

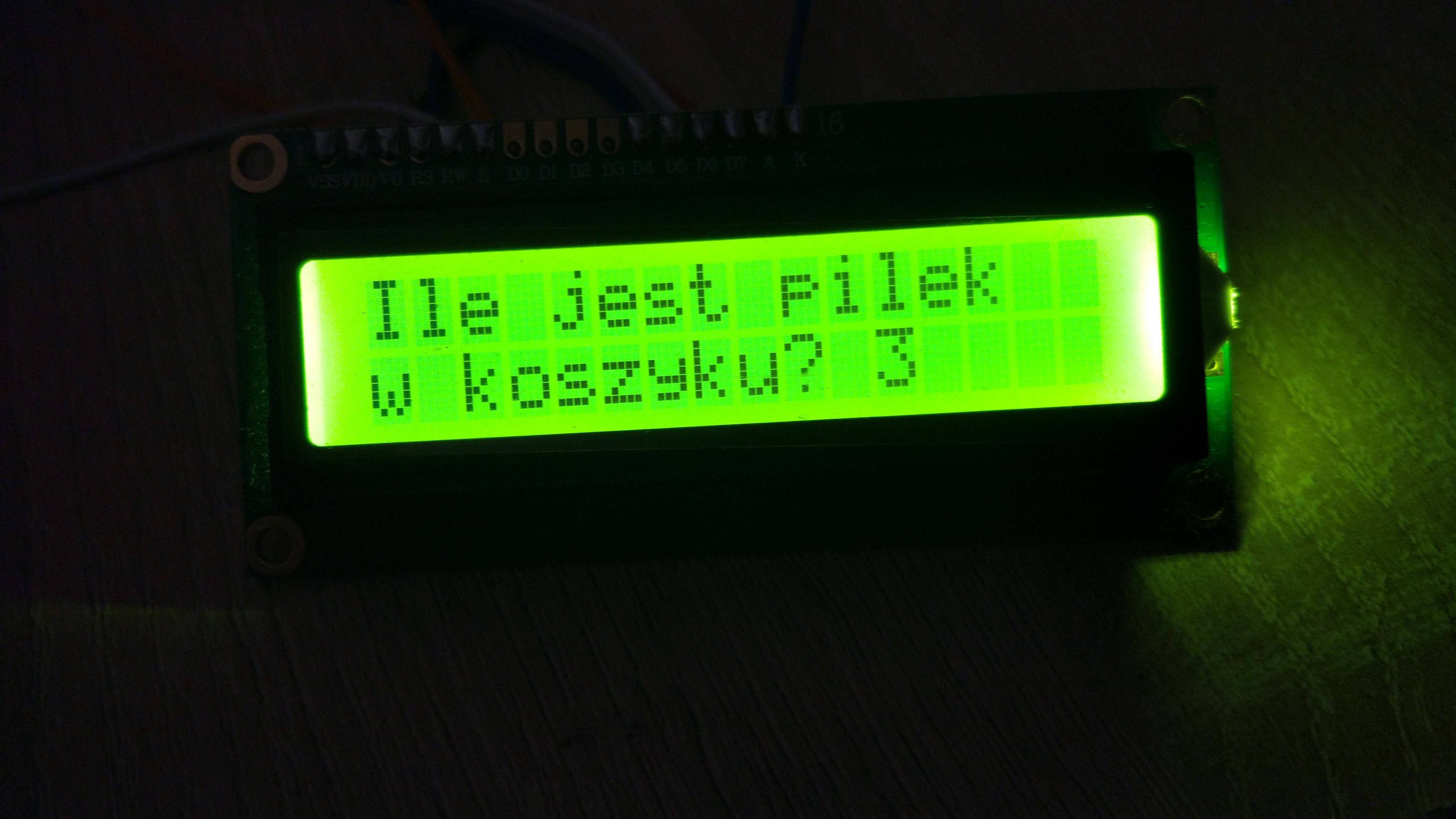

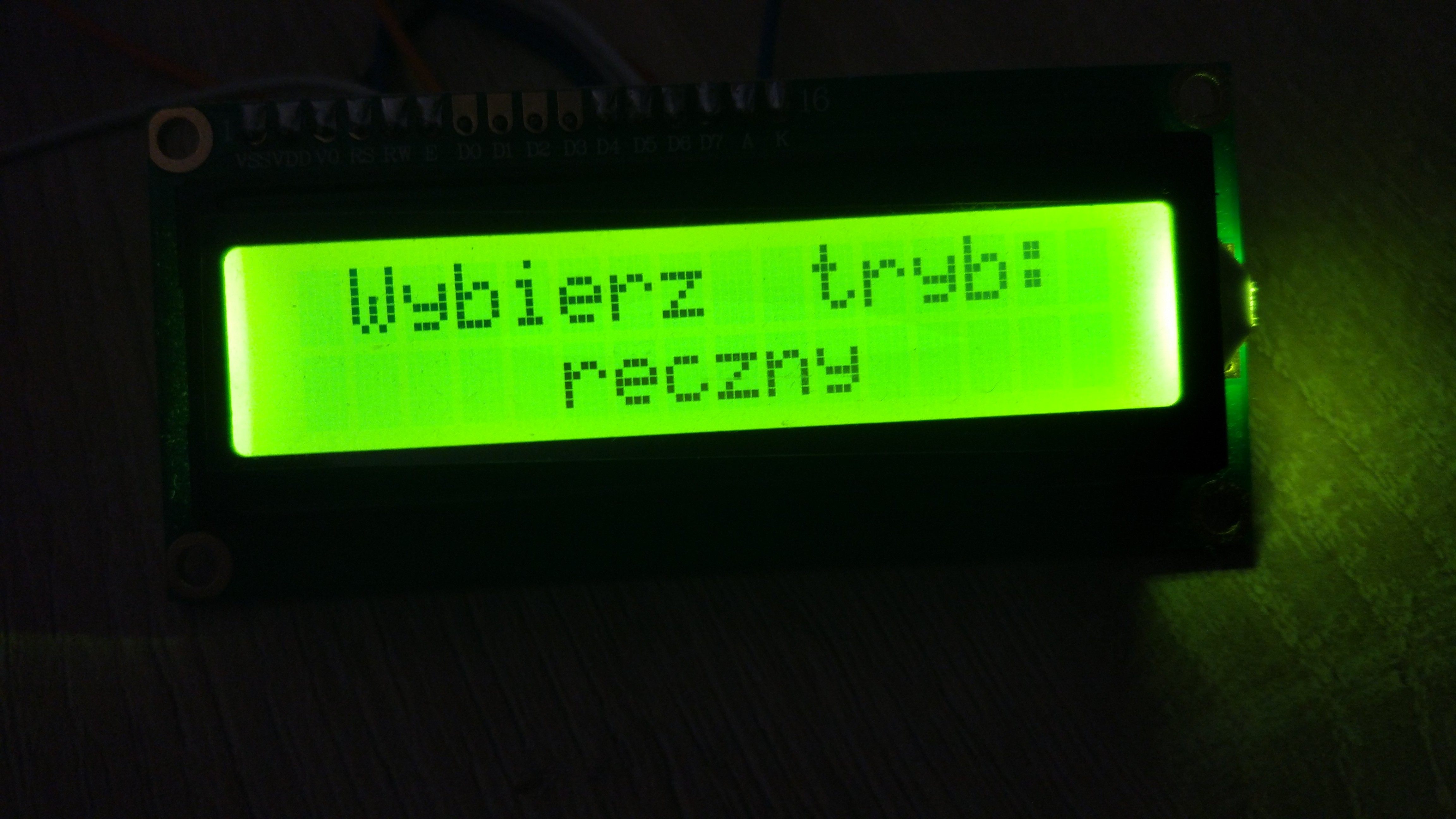

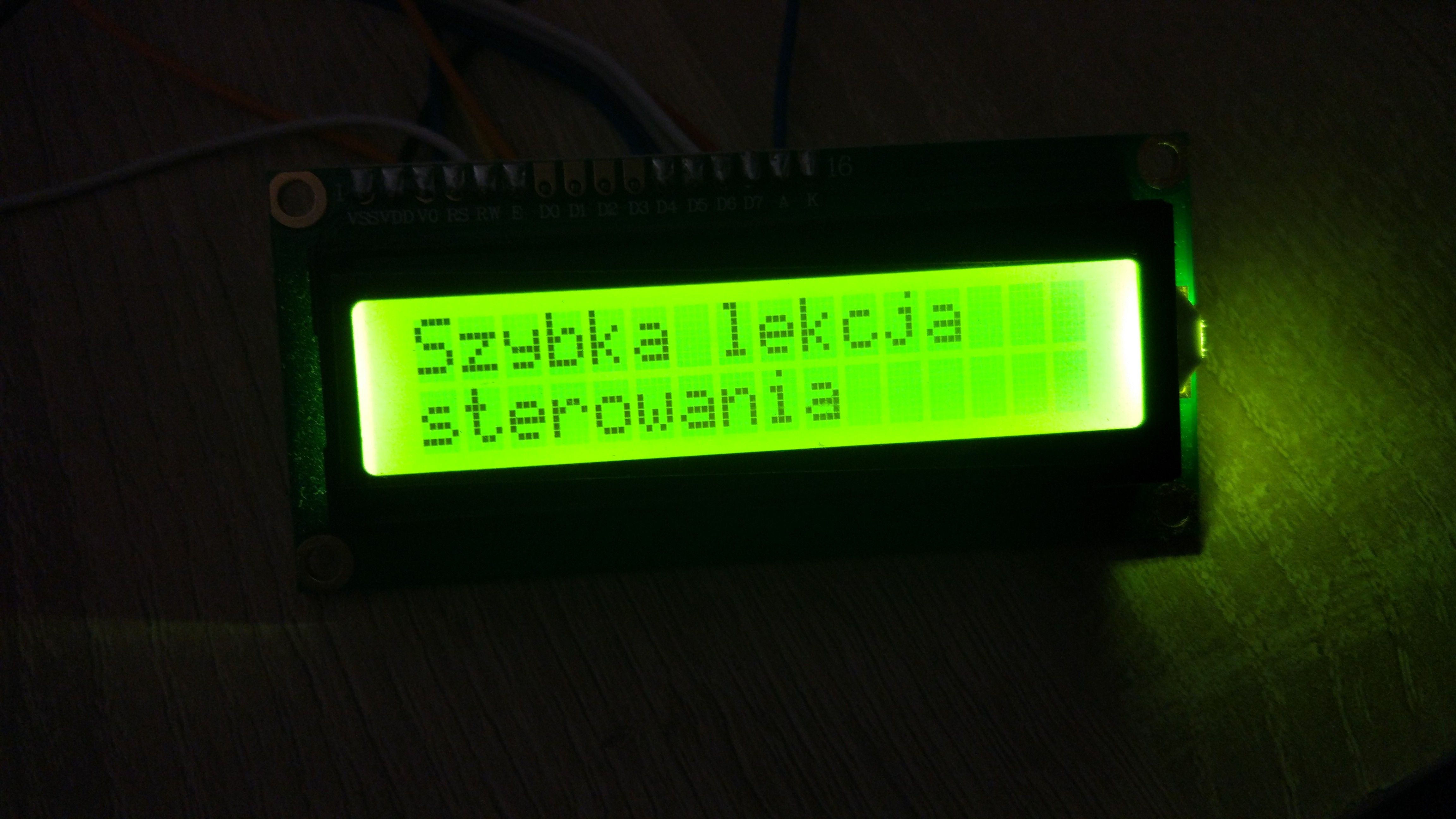

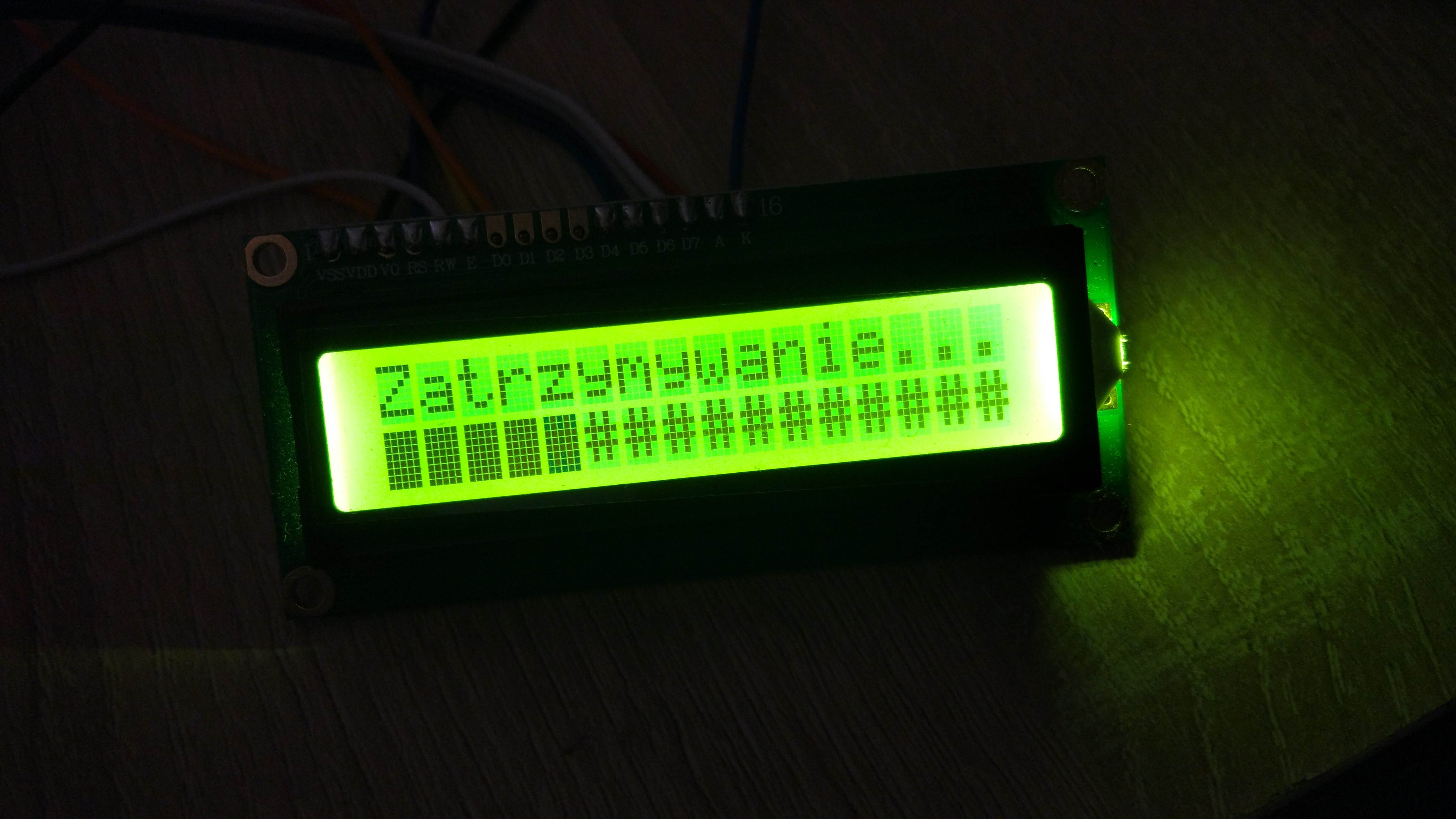

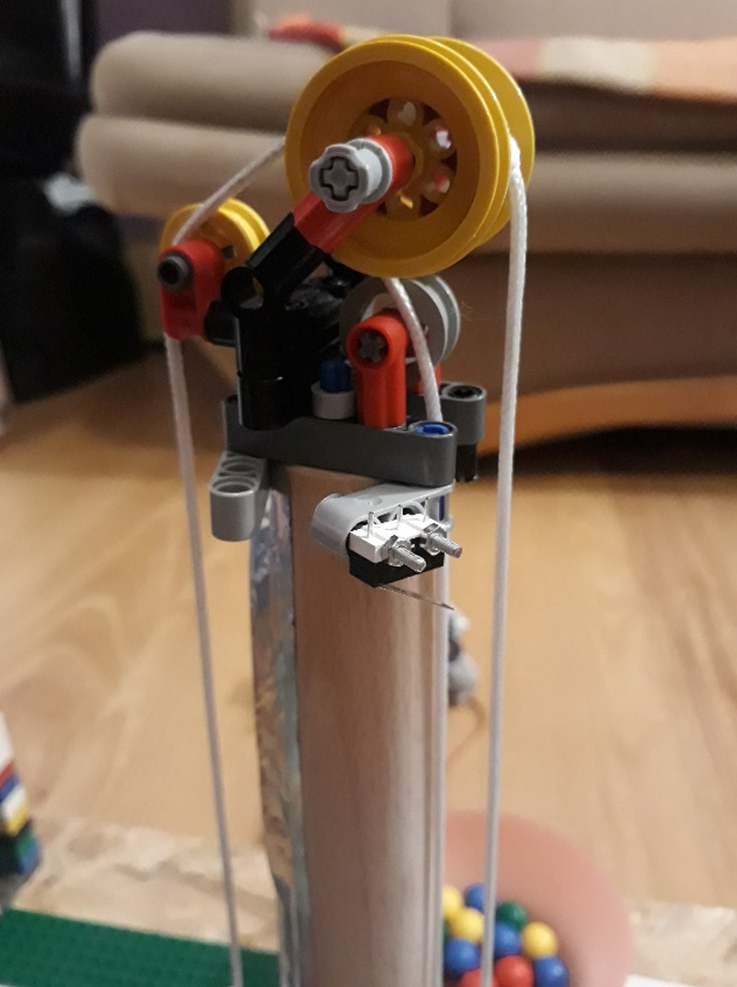

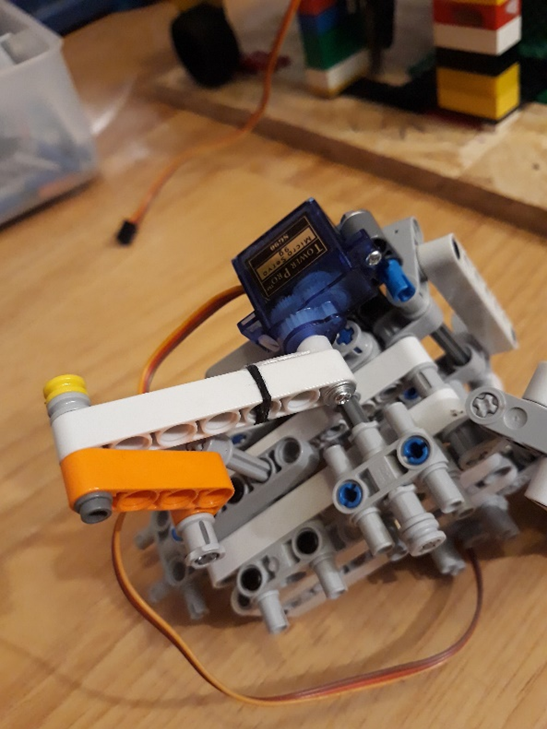

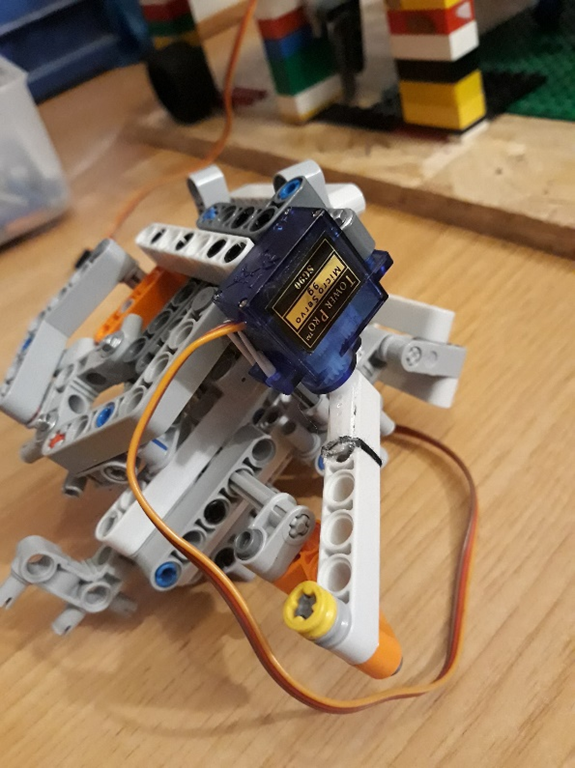

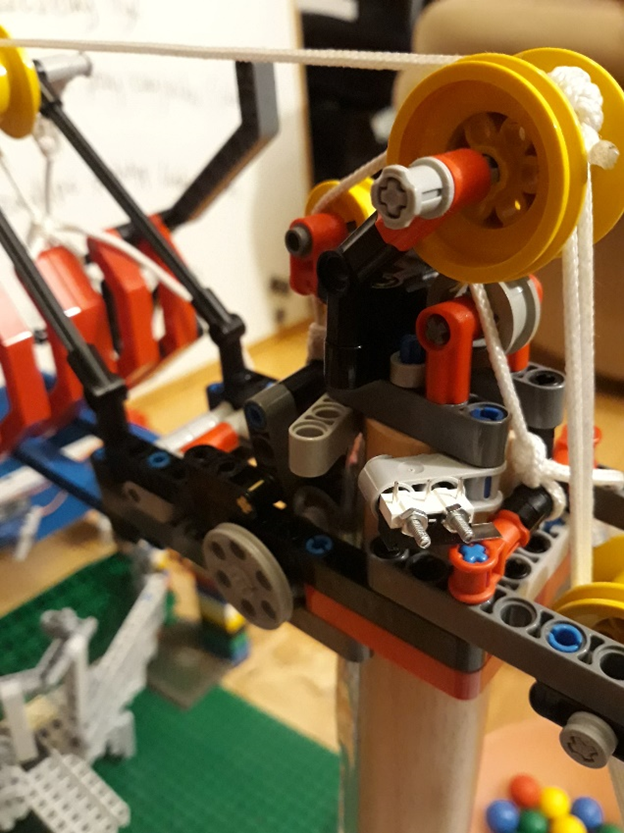

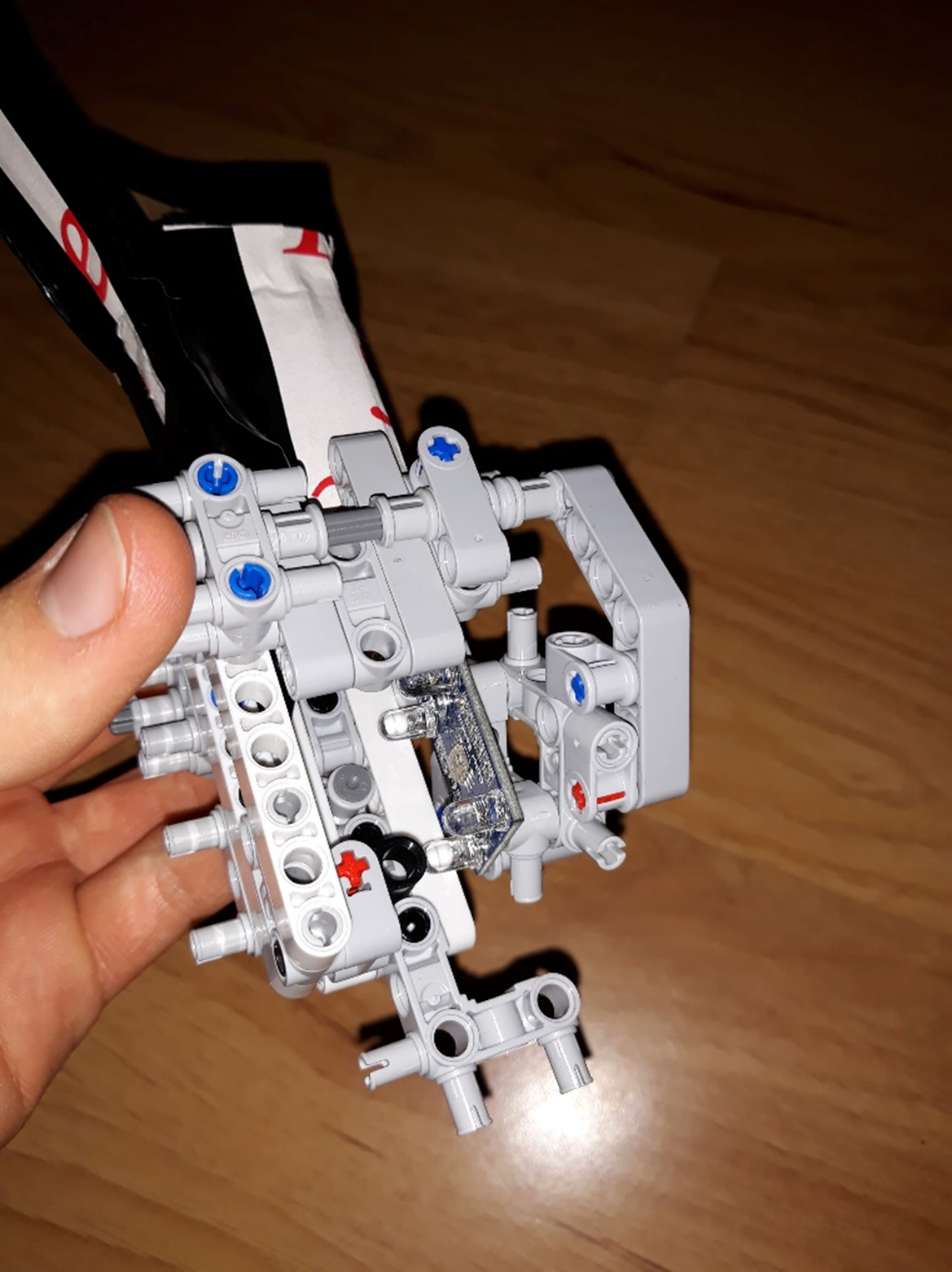

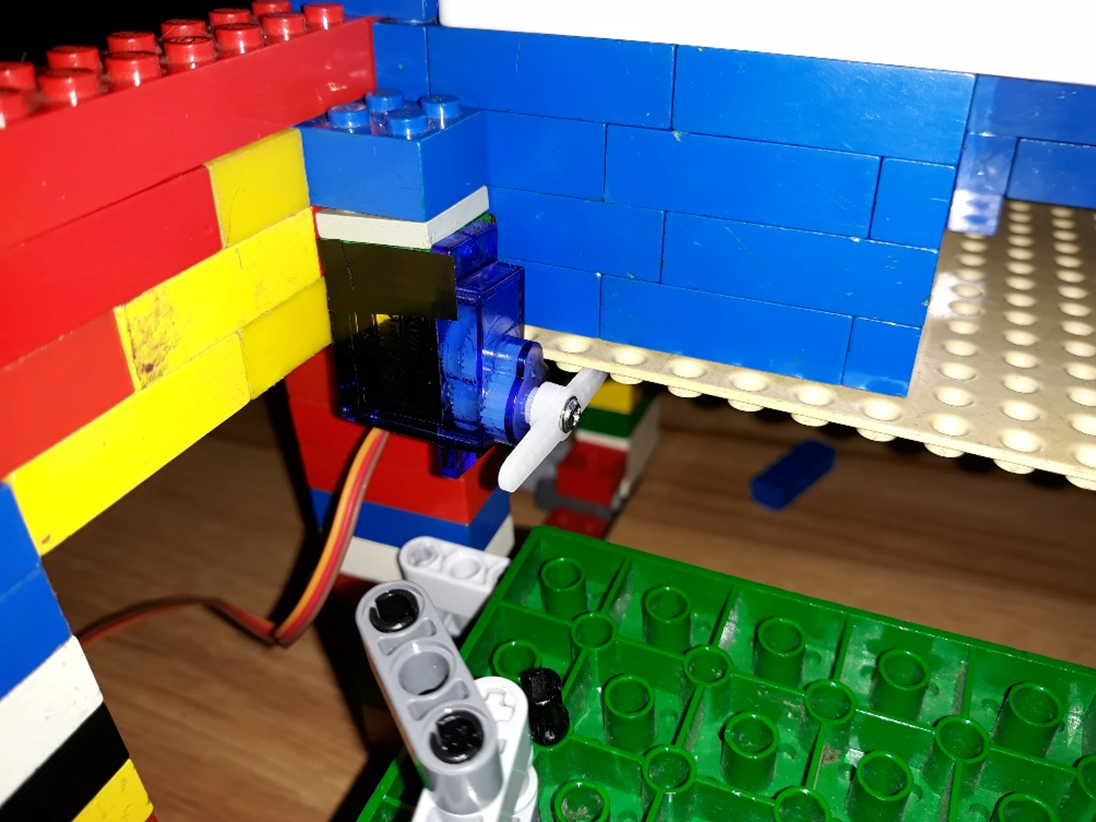

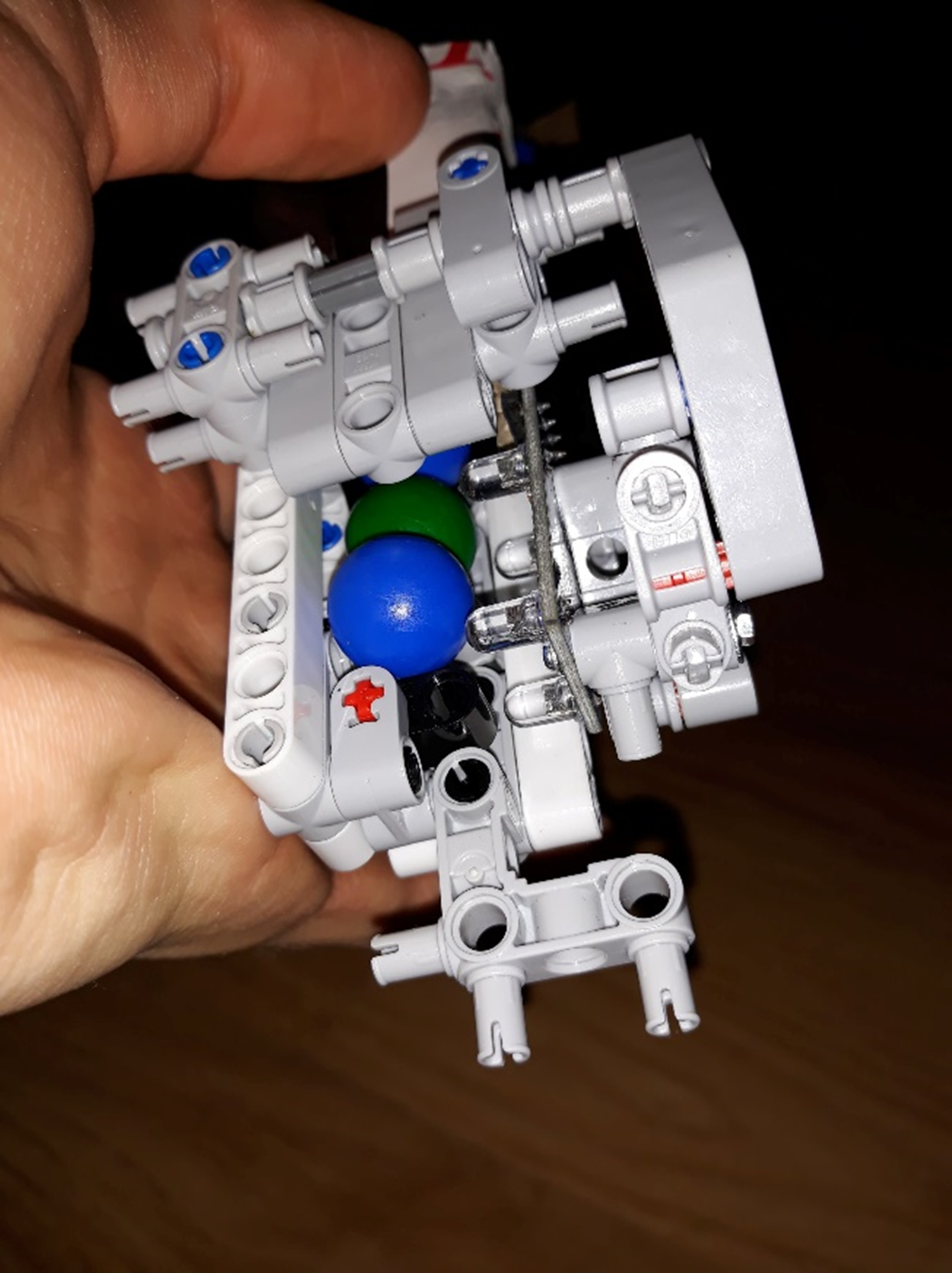

At the beginning, balls are located in container before color detecting module, which crucial elements are servomotor, yoke mechanism and RGB color sensor. Connecting yoke mechanism with servomotor allowed not only to prevent balls from moving forward before detecting it’s color but also allowed movement of one ball at a time after taking measurement. Afterwards, ball gets to rotating chute which distributes each ball depending on it’s color. The chute is connected to another servomotor, which depending on ball’s color rotates towards proper container where ball falls into. Following basic sorting mode, described process is repeated continously until there are no more balls waiting for being detected and distributed. After full sorting sequence, all balls can be piled up together due to moving floor (large, flat lego part) connected with 2 servomotors. Subsequently, balls move to module resposible for transporting them up. Well worked out construction of engine, rolls and strings proved itself by tipping the container with balls at highest point (detected by engine’s limit switch) and allowing balls to get to the initial place where they wait for their’s color to be detected and distributed depending on chosen sorting mode.

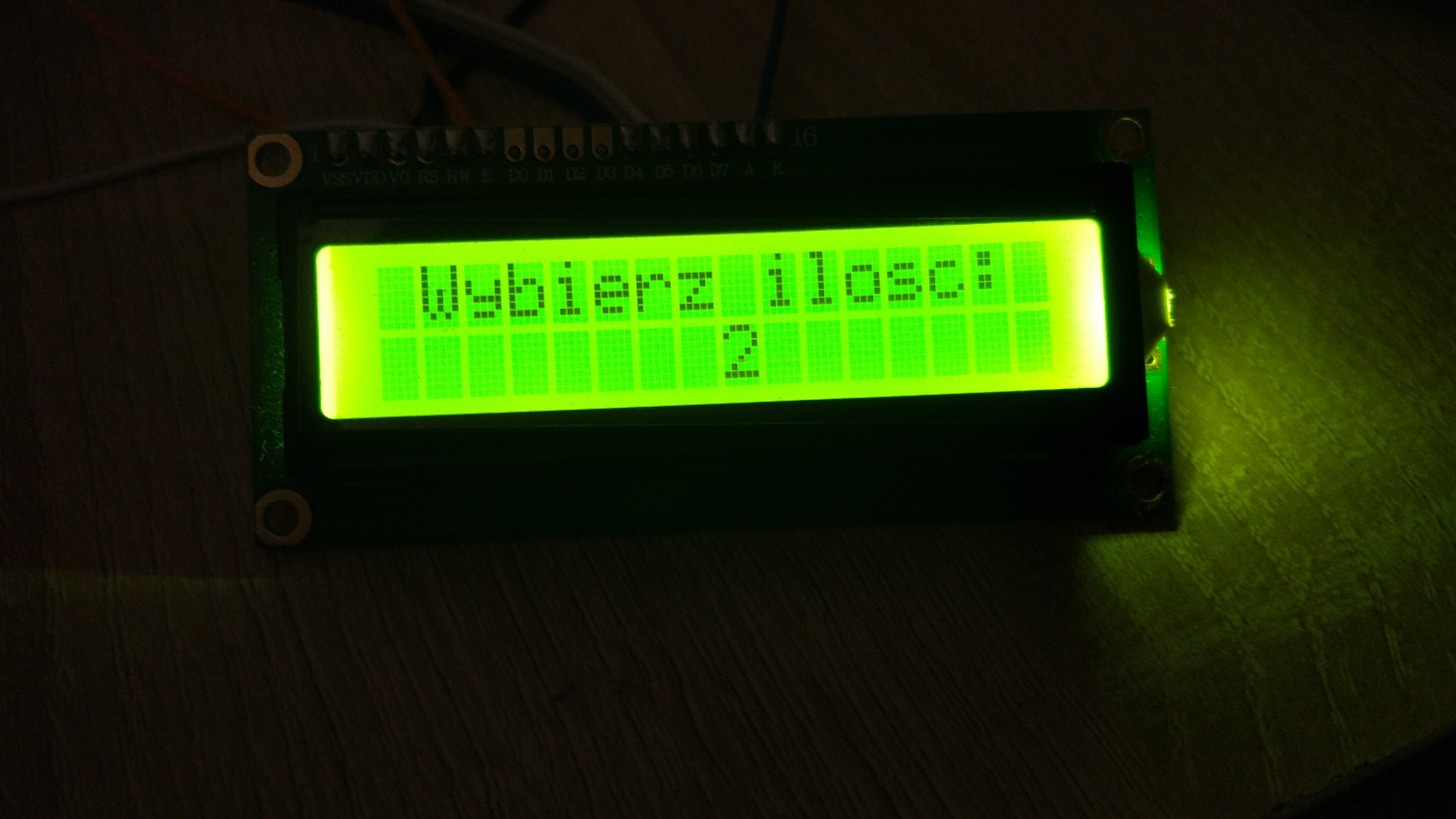

Electronics used:

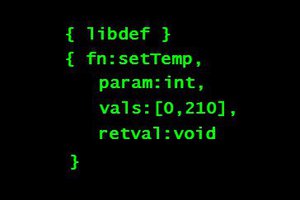

-Arduino

-Raspberry PI

-Color sensor

-Servomotors

Bitbucket link:

-codes for arduino/ RPI/ mobile app:

https://bitbucket.org/R3zn0w/kulowniksortownik/src/master/

Mechanics:

-LEGO Mindstorms and Lego Technic parts

CAD models (Fusion360):

Some parts were made in fusion360:

-Ramp with servomotor that seoarates balls to different containers:

-gear motor crane:

Pinterest account:

-All photos of sorting machine:

https://pl.pinterest.com/sortochad/

Youtube:

-Videos of working model:

https://www.youtube.com/channel/UChFFJiSFWzmPPpjXUeX_oAQ

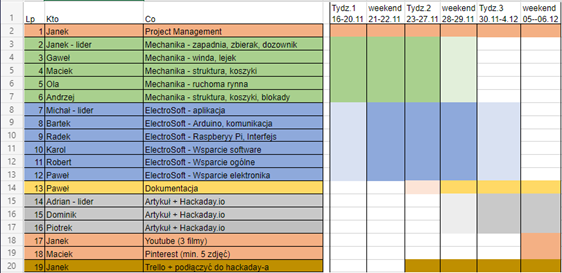

Project Management

At the beginning, decisions have been made who is going to work on specific fields concerning lego project. Therefore, 5 main subteams came into operation:

- Project Management

- Mechanical Team

- Software and electronics

- Documentation

- Report

Shortly afterward, waterfall schedule was instituted. It assumed the execution of our assumptions and targets at designated intervals.

Waterfall schedule of our work and goals:

Means of communication:

Microsoft Teams – regular videoconferences of our whole team, discussing weakly progress of every subteam, discussing completed, present and future tasks, expressing opinions about potential solutions, enhancements.

Facebook conversation - plentiful discussions, assigning tasks, conducting surveys, sharing ideas.

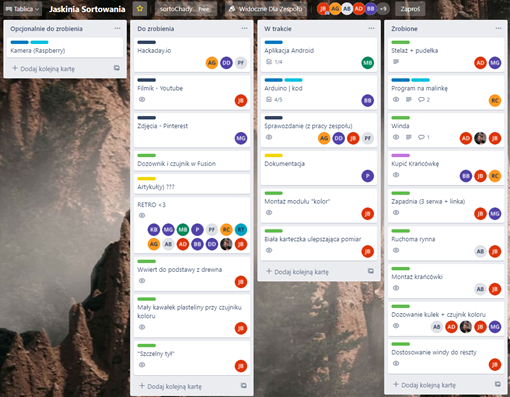

Trello – virtual kanban board, transparent view of every task assigned to person responsible for it, clear picture of what have already been done, what is in progress, what need enhancements, what will be done in the future and what is optional.

Daniel Sikar

Daniel Sikar

ProtoVoltaics

ProtoVoltaics

Anderson Antunes

Anderson Antunes