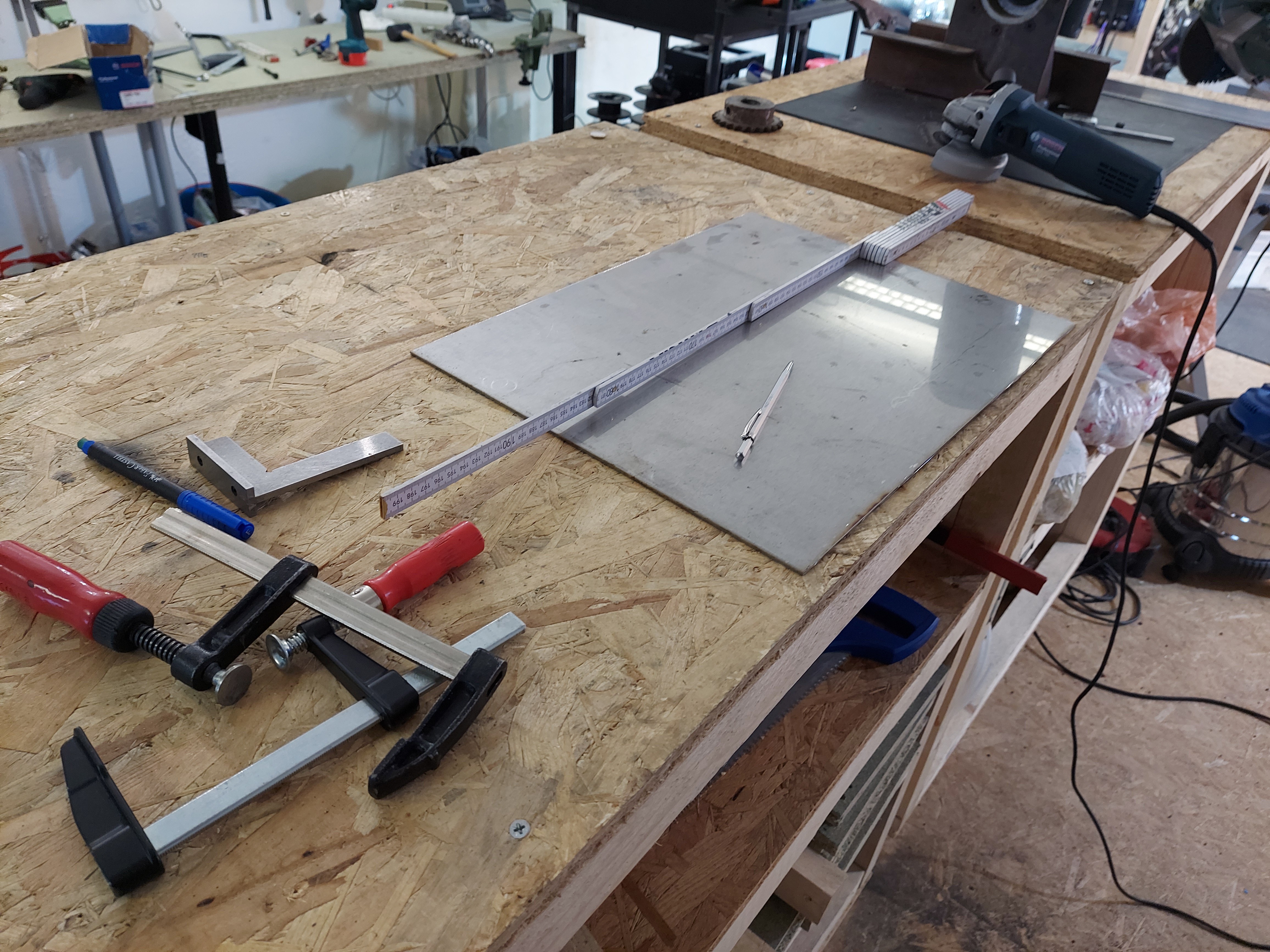

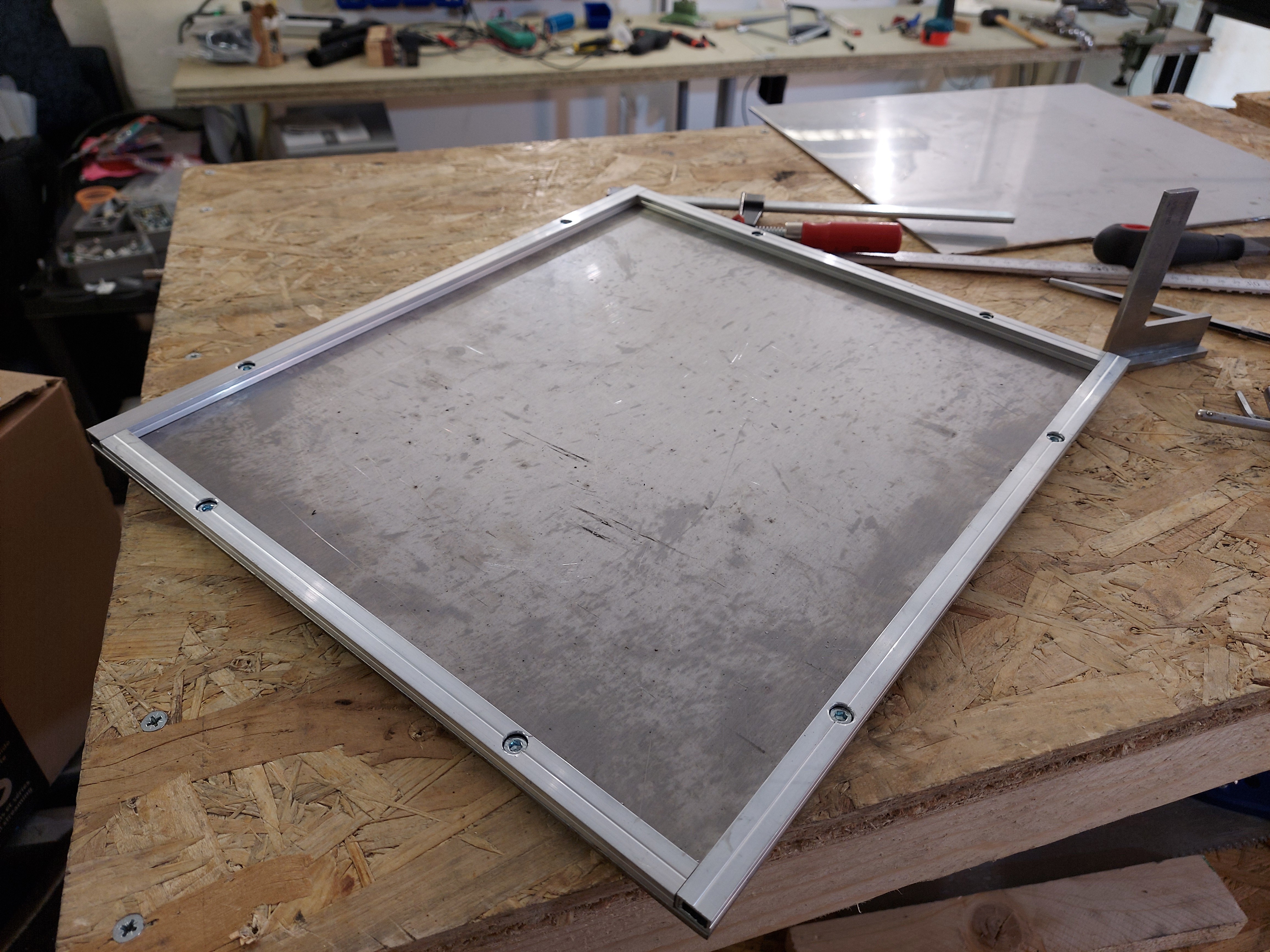

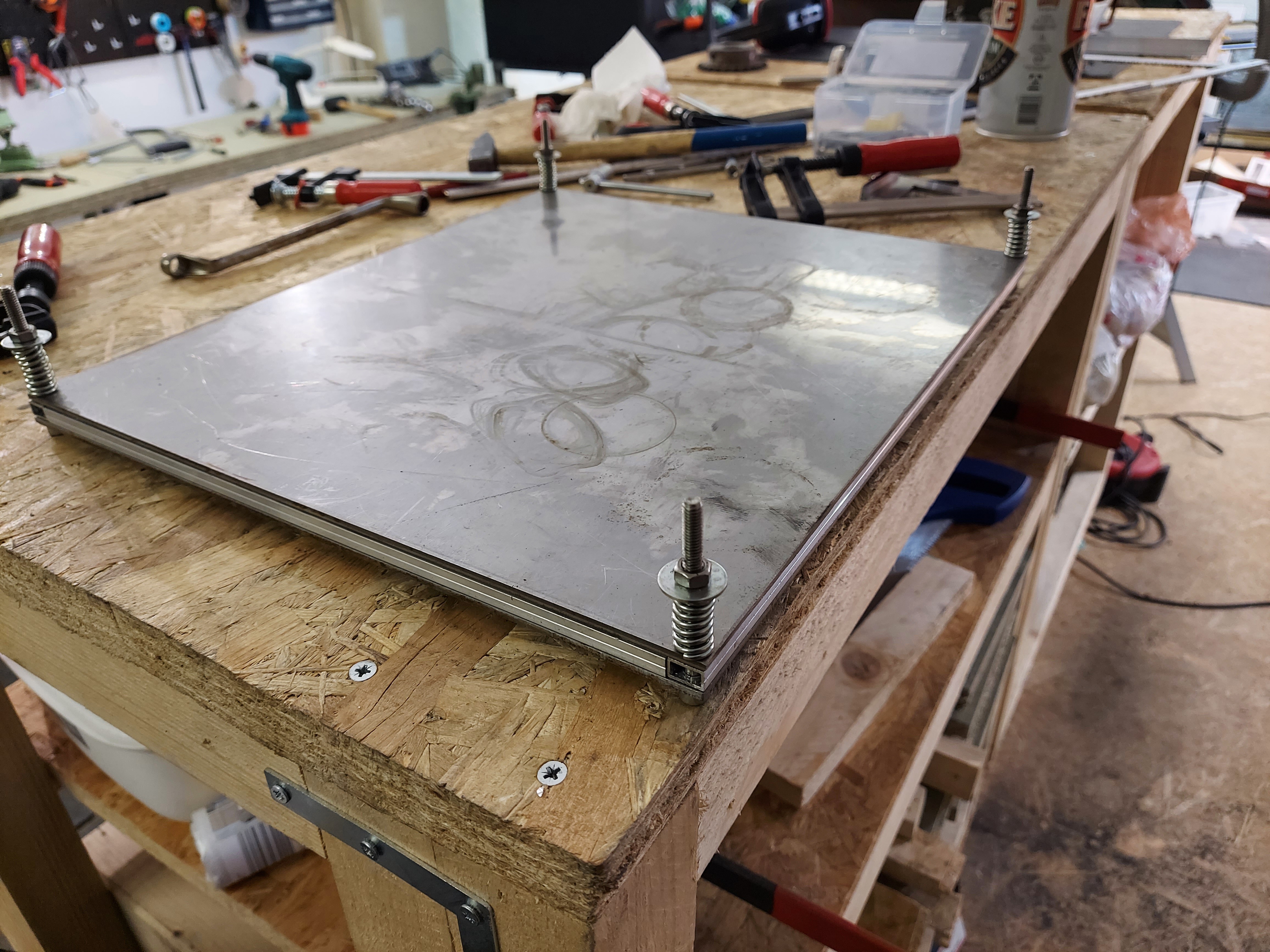

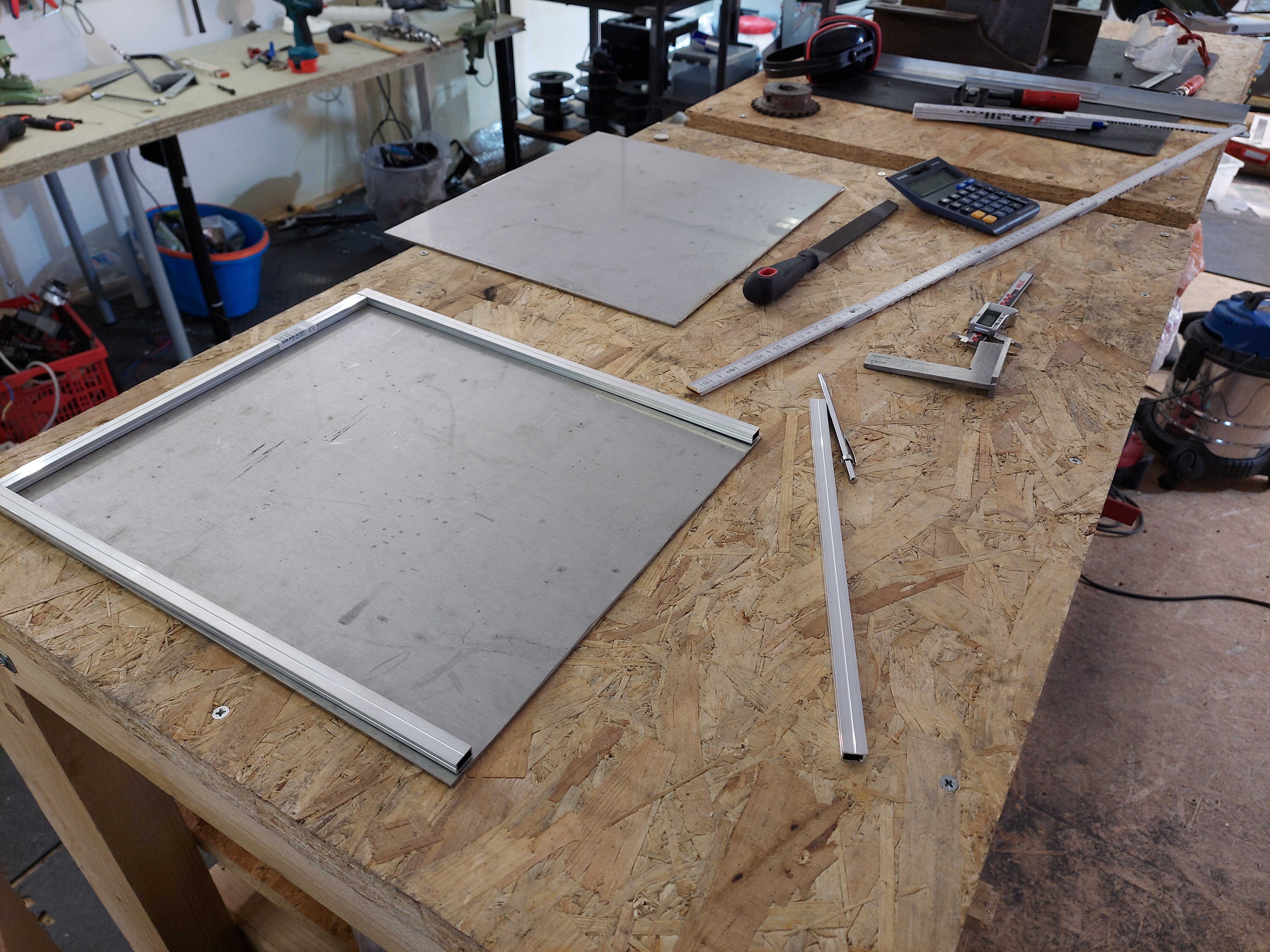

The first mold works, but it is costly to manufacture and relatively heavy due to the welded construction made of mild steel. In addition, fixing the frame and lid via 12 screws is not always that easy. The new approach does not require any welding at all. Instead of individual plates, a large stainless steel plate is now used for the base and lid, which we received last year from a household / workshop liquidation. The frame elements are sawn from simple aluminum profiles and screwed to the plate by drill holes. This form is again scalable, in which simply several frame elements can be arranged on top of each other. Pressing pressure is also generated in this form by pretensioned springs.

DevLab.nrw

DevLab.nrw

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.