-

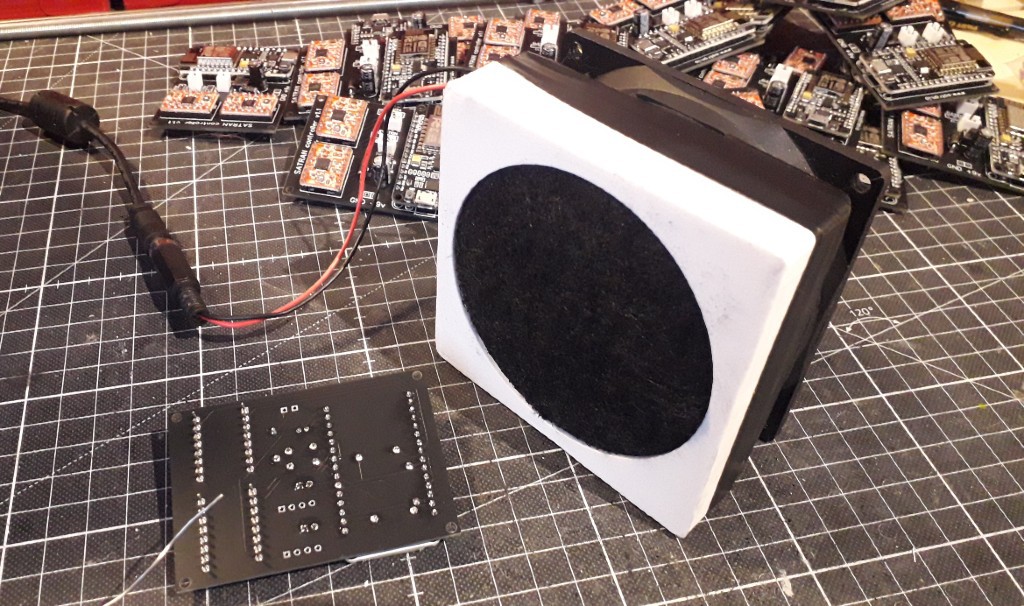

Suck up all the fumes

03/20/2021 at 15:21 • 0 commentsWhen you have 50 circuit boards to solder in a row, the fumes can get quite annoying and unhealthy. Thats why I built this very simple but efficient solder fume extractor.

![]()

An old computer fan, a 3D-printed housing and two layers of an active carbon filter stolen from a kitchen fan. Removes pretty much all the smoke and smell and cost me more or less nothing. A very good investment in my health and sanity.

-

Getting organized

03/19/2021 at 08:12 • 0 commentsBuilding a prototype is a whole different arena than mass production. Thanks to the large interest from all over the world, I am scaling up this production run, so keeping all the parts in a big box just wont do it anymore.

![]()

Since every single part is needed before I can start to ship every kit, inventory management is something I am slowly developing, using classic lean management techniques. There are lots of bottlenecks to solve still, but being able to produce five times as much in the same time frame is a big accomplishment for me. Hopefully you have the patience to wait a little bit longer before I can meet the demand.

Getting the product in the hands of amazing satellite enthusiasts and ham radio operators is my main priority. And I am loving every second of it...

-

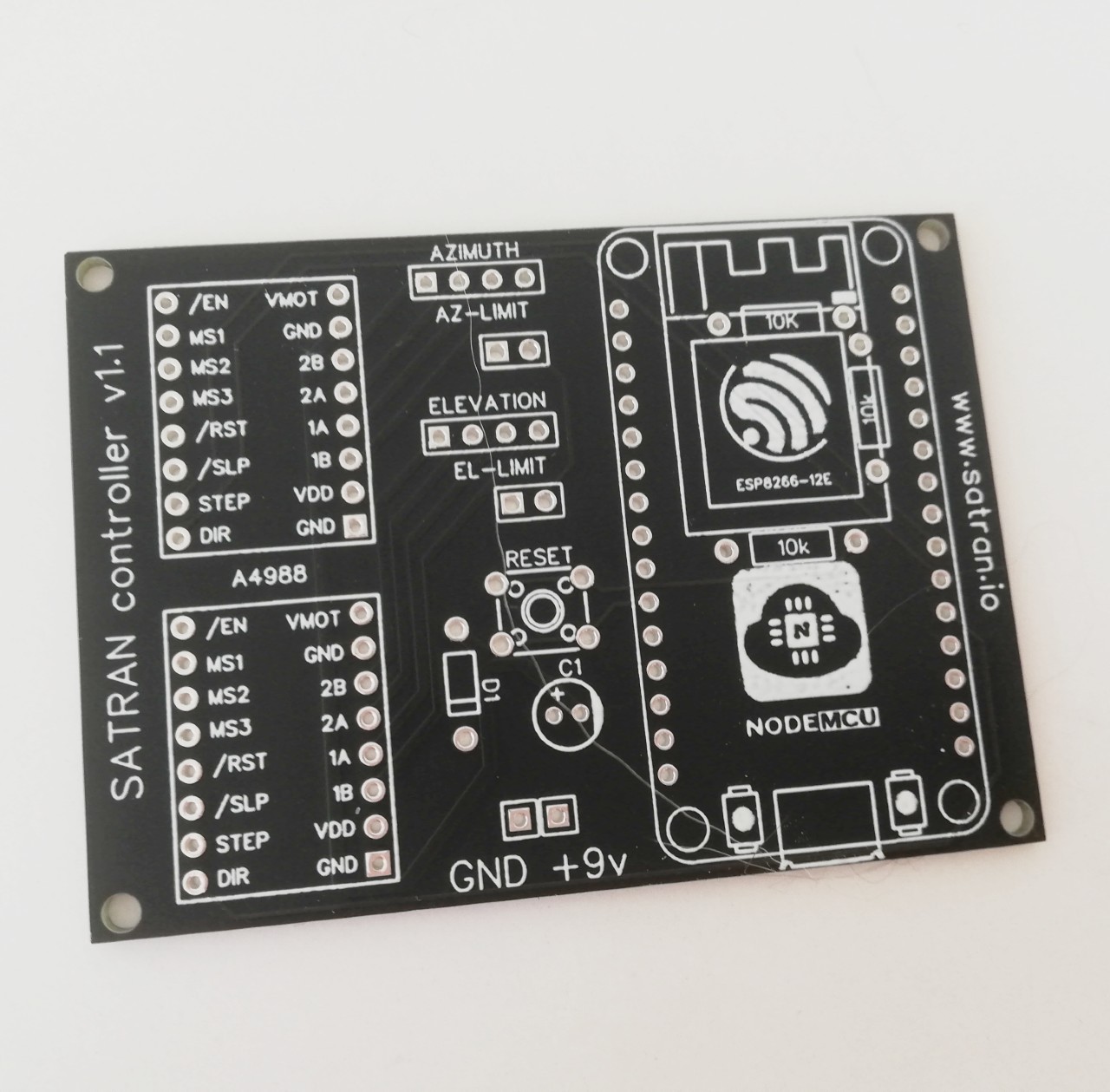

Small adjustments, big impact

03/10/2021 at 06:16 • 0 commentsThe new batch of PCBs arrived a week ago and I've started soldering all the components. This time the goal is to put up 50 kits for sale on the site, which means a lot of work but also lots of fun.

![]()

I updated the board to v.1.1 but there arent any big changes. The major change is nothing more than a bigger capacitor of 200uF instead of 100. It seemed that the smaller cap could give an unstable current or voltage spikes from the stepper drivers, that resonated in the stepper motors sometimes giving of an audible noise.

Also the text is a bit different, with the new website address and also the copper tracks for the power is wider to make sure it can handle all the power, but maybe this also had something to do with the strange whining sound. All in all, they work perfectly now.

-

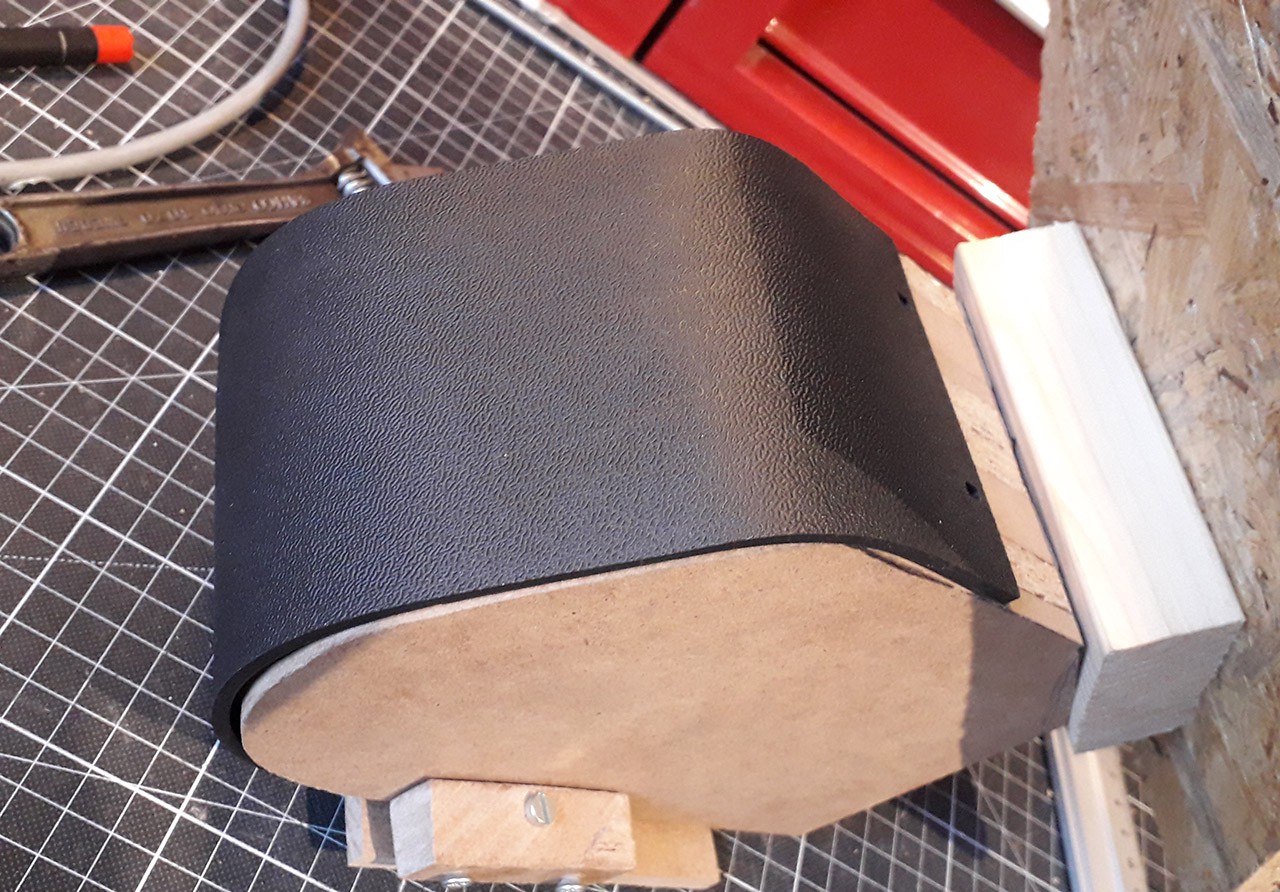

Thermobending the cover

02/26/2021 at 13:54 • 0 commentsThe top cover is made from 3mm ABS, that needs to be bent in a U-shape. Sounds easy, but it takes quite a lot of effort to give it a perfect shape. Warming it up with a heat gun and bending it over the table is not the way to go.

![]()

This might look like a droid, but its actually my simple but effective drape mold. I put a CNC-cut sheet of plastic on the mold, fasten it and put the entire thing into the oven for a few minutes. When it comes out, I gently bend it around the mold and wait until it sets.

It works really good, but I think I need to make a negative mold also to get a completely smooth surface and spare my poor hands from the intense heat.

![]()

-

The new website

02/20/2021 at 09:50 • 0 commentsSince all the info and data for the Satran has grown, so has the number of followers. Therefore I couldnt host it all on my own website, so this week I put together a new website that is now available at www.satran.io

![]()

Check it out!

-

The first kits have been shipped

02/16/2021 at 14:48 • 0 commentsI can hardly believe its true, but what was just a hobby project a few months ago is now the beginning of a new business. Today I modestly opened the webshop and the first kits sold out in minutes and are now on their way to early adopters across europe. Since I couldnt afford to buy components for more kits the stock was very limited, but things will ramp up quickly.

![]()

The next production run has already started, which will consist of around 50 complete kits. My apartment will surely get cramped, but its worth it. Even if I won't get rich on the kits, its an amazing feeling to make money from your passion. And to be honest, I think my passion for the tech is what people want to be part of. Also, since I was more or less unemployed last year this has been a true salvation.

No matter if you're planning on buying or just like to follow and share the project, I can't even describe how thankful I am to you all. You are the best!!!

-

A great project deserves a good logo

02/14/2021 at 21:25 • 0 commentsSince I'm planning for a dedicated website, a nice logo is a must. This is the first draft, but it turned out quite nice. But perhaps make it even more minimalistic to look good even in smaller sizes or with less color.

![]()

-

Drape mold for plastic cover

02/12/2021 at 06:48 • 0 commentsThe last parts are almost finished. The sides and top cover will be made of CNC-cut ABS plastic sheets that should arrive from the manufacturer on monday. Since my own CNC mill broke down I had to find a local producer instead, but that will pay off anyways when I scale up from a handful to perhaps a hundred kits in each run.

The top cover then needs to be thermoformed in a U-sized shape. That is why I'm making a mold right now, on which I can drape the heated plastic. Just put the sheet in an oven for a few minutes, take it out and bend it around the mold. I'll try to hold it in place with two straps as you can se in the pic. Will it work? Time will tell.

![]()

-

It's getting closer

02/08/2021 at 13:30 • 0 commentsAfter the previous challenge of finding suitable plastic sheets, I finally stumbled upon a local manufacturer who could assist me not only with the material, but also CNC-mill the parts at a reasonable price which saves me a lot of time.

That means the very last parts are soon in stock. What intense months it has been.. I can hardly believe that its finally done. There's even some time to tweak the firmware and check a few extra times to make sure that there arent any bugs before I open up shop. Because when it's shipped it's out of my hands and any critical errors means I have to send the customer a new board.

Exciting times.

-

It's always the simple stuff

02/04/2021 at 08:13 • 0 commentsWell, production was going quite smoothly. My goal was to offer the first kits this or the next week, but of course one of the last parts are giving me a huge headache. To make it even more entertaining, it's the most simple and inexpensive of all; 3mm plastic sheets...

![]()

You would think that finding simple sheets of black plastic should be easy. But apparently not in Sweden. It's litterally impossible to find a supplier that can sell you anything less than 500kg!! And importing takes way too much time. But I might have found a retailer in germany that should be able to help, even if it adds a week or two of production.

Also on top of all, the hard drive crashed in my beloved CNC-machine. I have already ordered a new disc, but finding all the correct settings and calibrations again makes me wanna cry. Whyyyyy?!!?!

Oh well, you just have to roll up your sleeves... To swear a little also helps.

SATRAN - Satellite Tracking Antenna

Wifi-controlled, azimuth/elevation antenna rotator.

Daniel Nikolajsen

Daniel Nikolajsen