-

The first production run

02/01/2021 at 11:22 • 0 commentsProduction has been ongoing for some time now, and there's only a few more components to arrive by post before I can offer customers the first kits. However, the first batch won't be as big as I would like, but its a good start. If you count all individual components, there are approx 150pcs for a single kit. Some needs to be soldered, some needs to be 3D-printed, while others just needs to be counted and put into bags. On the schedule today... shortening of the stepper motor cables.

![]()

-

Checkout the video!

01/30/2021 at 20:29 • 0 commentsThe prototype is working like a charm, even if some bug fixes and tweking remains. But just to tease you a little, I put together this nice video for my youtube channel...

-

Where's the sat at?!

01/22/2021 at 15:44 • 0 commentsWhat do you think? Its starting to look quite nice, with my 70cm yagi added. The weight is somewhat balanced now with my improvised weight in the rear of the antenna. Next week it's time to shoot a video, but now a well earned beer is top of my priorities since this week has been 16 hour work days. cheers!

![]()

-

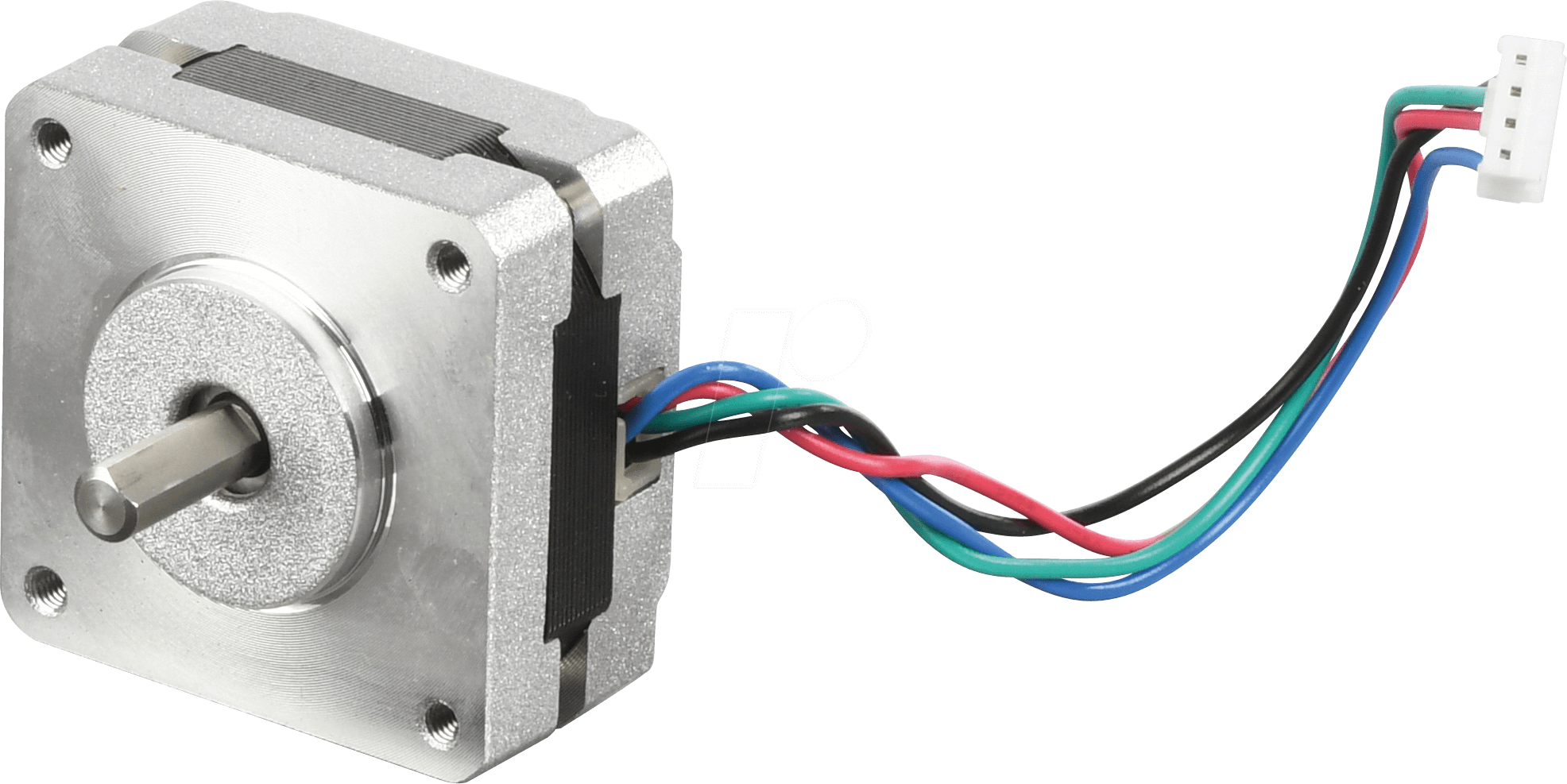

Lesson learnt on stepper motors

01/22/2021 at 06:12 • 0 commentsI am now in the final tweaking stage of the project. Getting sensors to work mostly without any glitch, and tuning the stepper drivers to make the torque as good as possible without overheating or breaking anything.

For almost a full day I struggled with getting any decent torque from my stepper motors. The A4988 driver has a built in circuit to limit the current with a trimpot to adjust it, but no matter what I did the motors gave off some crazy whining sound and never took more than about 200mA, and were so weak that I easily could halt the motors with my fingers.

![]()

But then, after a fresh cup of coffee, I read the datasheet for the motor and realised... Resistance! The motors I had were 10 ohms. So I switched to 2.8ohm motors instead, and bam! A full 1 amp current. Now the rotor should be able to turn the antenna without any issue, but the exact specs are still to be tested...

We're getting somewhere!

Also the response I have gotten from all over the world has been amazing, I cant thank you all enough. From more or less being unemployed due to covid last year, I am now working day and night to finish the design. Lots of people are requesting to buy the kits, and if you havent already - subscribe to the newsletter on my site to get reminded when stuff gets released, because the first kits and circuit boards will probably sell out in minutes. Also, thanks to you and others who have donated to the project I will try my best to keep as much as possible under open source, including the android app I am developing.

-

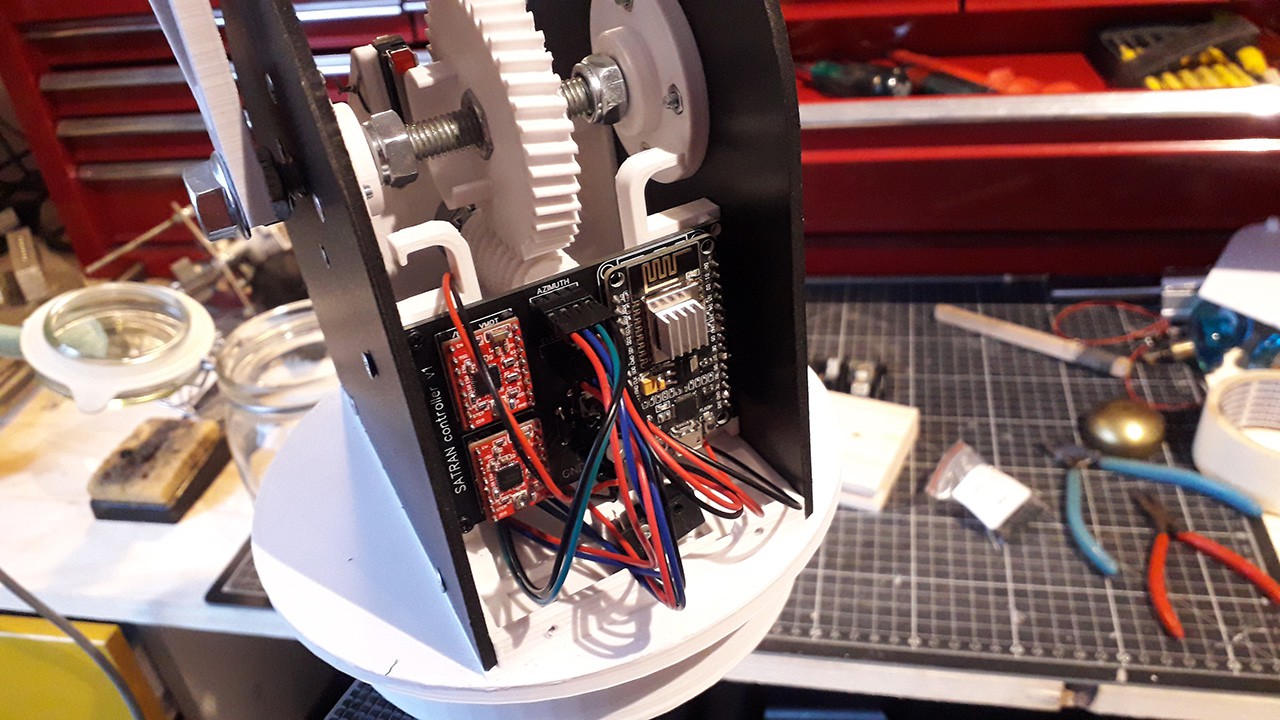

Last pieces come together

01/16/2021 at 14:46 • 0 commentsThe final prototype circuit board is now finished, with a NodeMCU and two stepper drivers soldered directly onto the board.

![]()

Also the first firmware is finished and I can start testing it out. The first attempts worked fine, but I need to tune up the stepper drivers to give some more torque. They can handle at least 1A but are only pulling around 0.2A right now.

Next it's time to get the android app together...

-

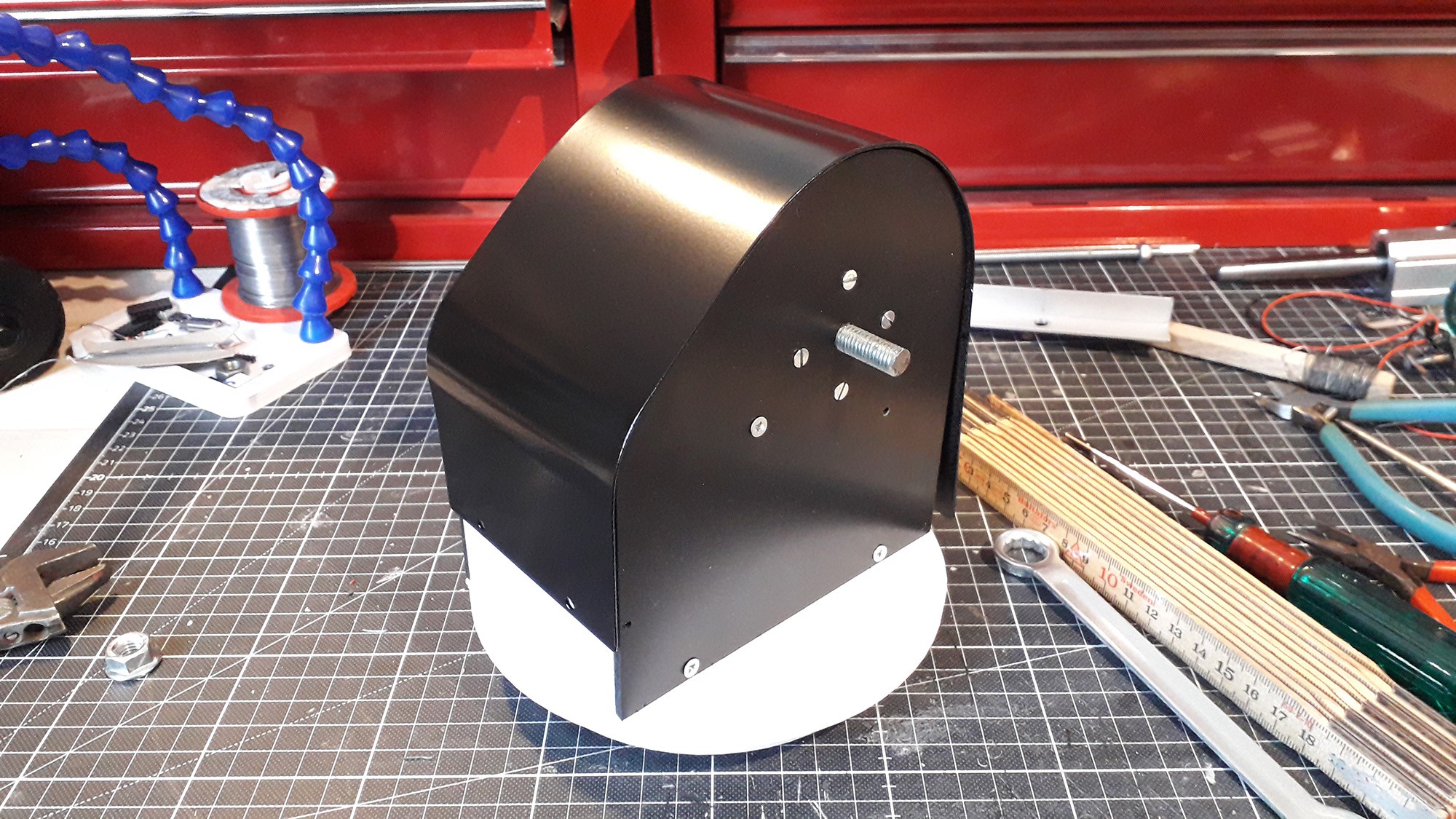

Hack in Black

01/15/2021 at 11:07 • 0 commentsNothing beats a semi-gloss black finish. All the 3D-printed parts are also supposed to be black when I start production but I had a lot of white filament that had to suffice for the prototype.

Also I am awaiting a shipment of nice black screws for the finished kits, the plated ones on the prototype are just stuff I had laying around.

![]()

As you can see I have also fitted the first CNC-cut sides in black plastic, and also painted the top aluminium cover.

The firmware is also coming along steady so hopefully I can present you with a demonstration video within a week.

-

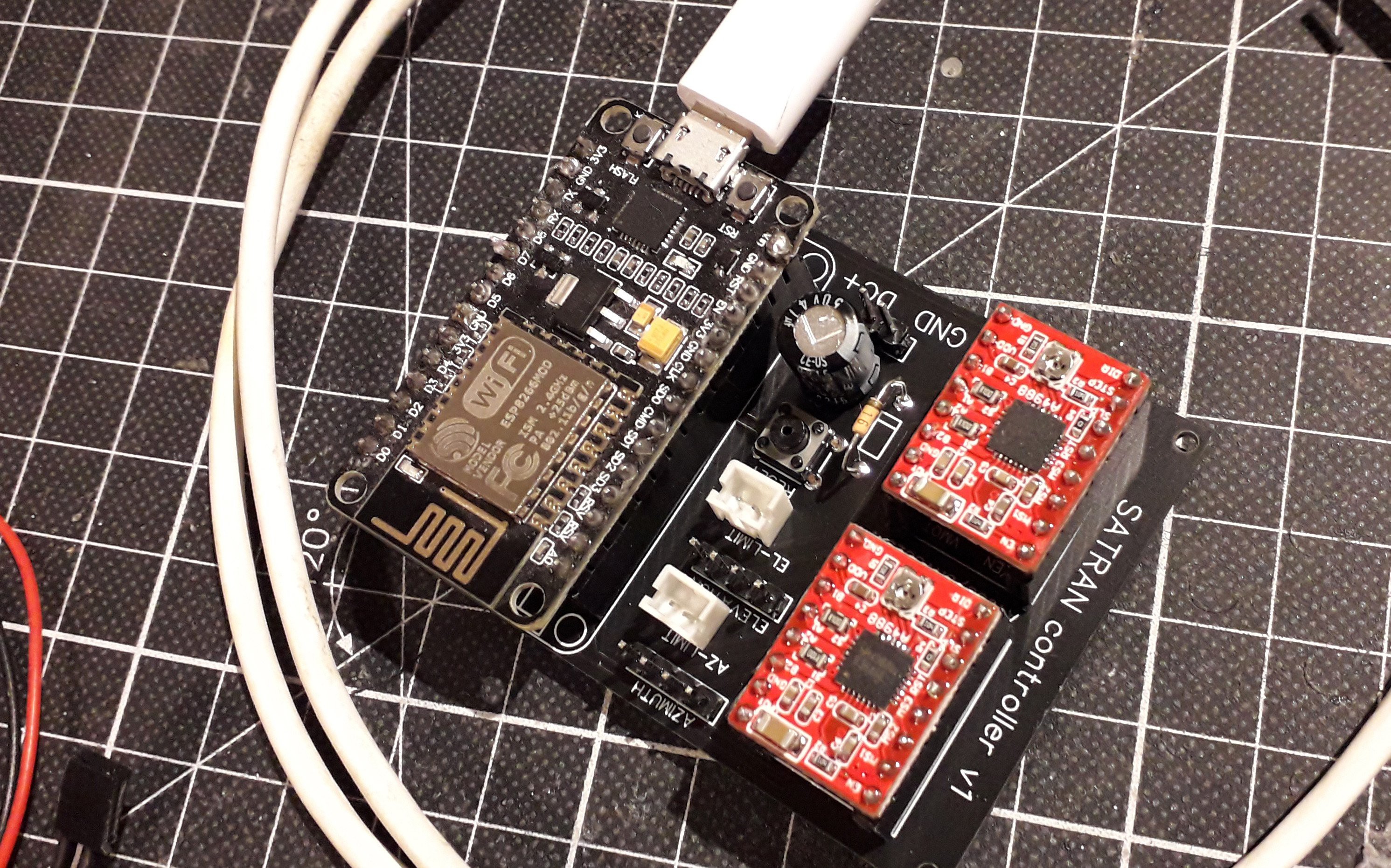

Time to test the firmware

01/13/2021 at 19:53 • 0 commentsThe very first prototype circuit board has been soldered together, and the first trials have worked perfectly!

However, there are a lot of features left to code for the "firmware". But as of now it can create a wifi access point with a setup page, and then store your wifi credentials and run a web server on your local wifi. Also it can turn two stepper motors without any hickups, but I couldnt try the limit switches today since i was missing some resistors.

![]()

All in all, everything is going according to schedule...

-

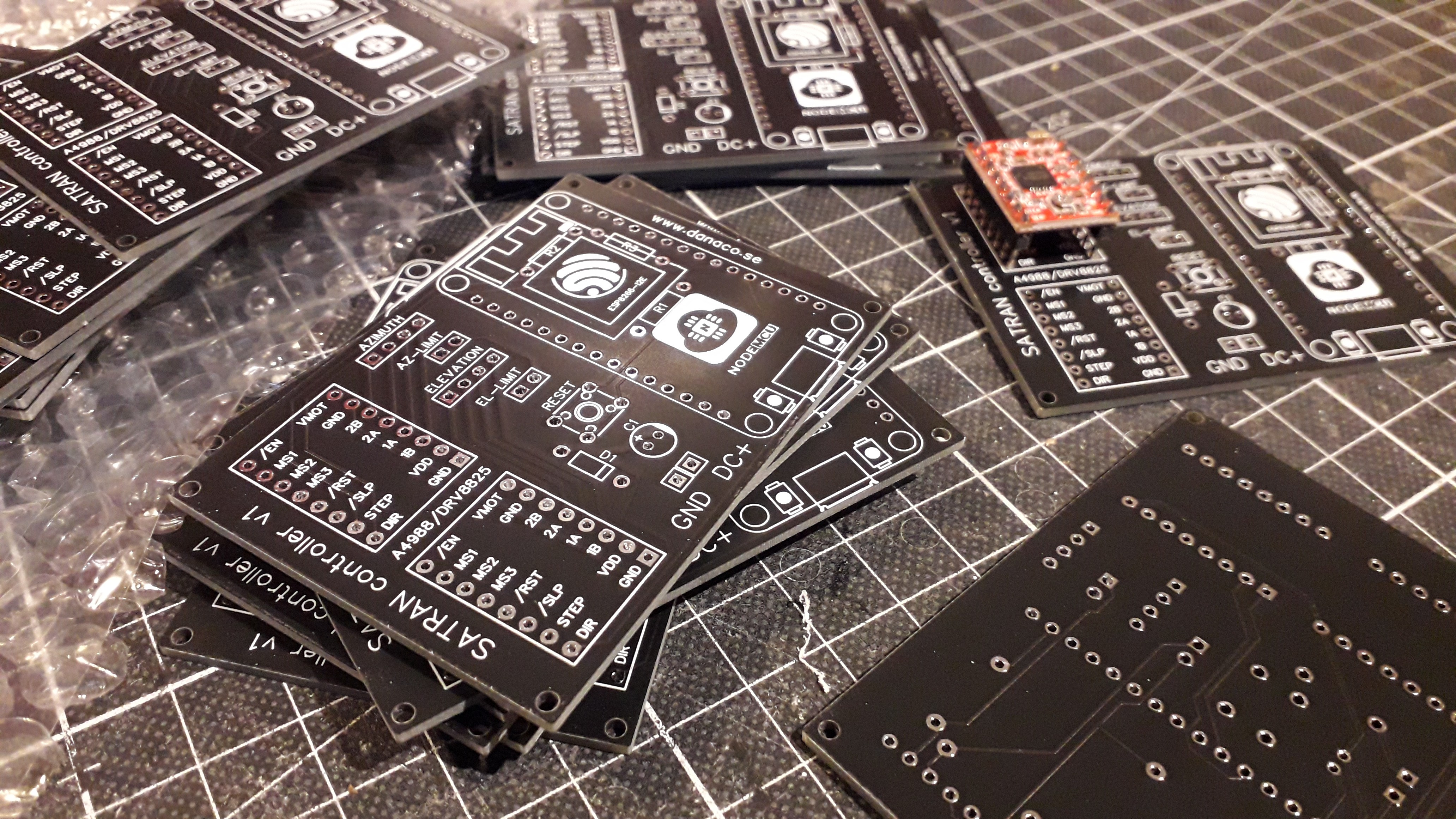

The circuit boards are amazing!

01/11/2021 at 15:03 • 0 commentsToday the PCBs arrived from china. Absolutely amazing! It almost angers me how skilled and cheap the asians are, but for my project it's crucial to be able to buy a batch of prototype circuit boards without breaking the bank.

![]()

Everything was beyond expectation. Perfect fit, precision and hair-fine screen print on top. Time to get the soldering iron out and put together the very first prototype...

-

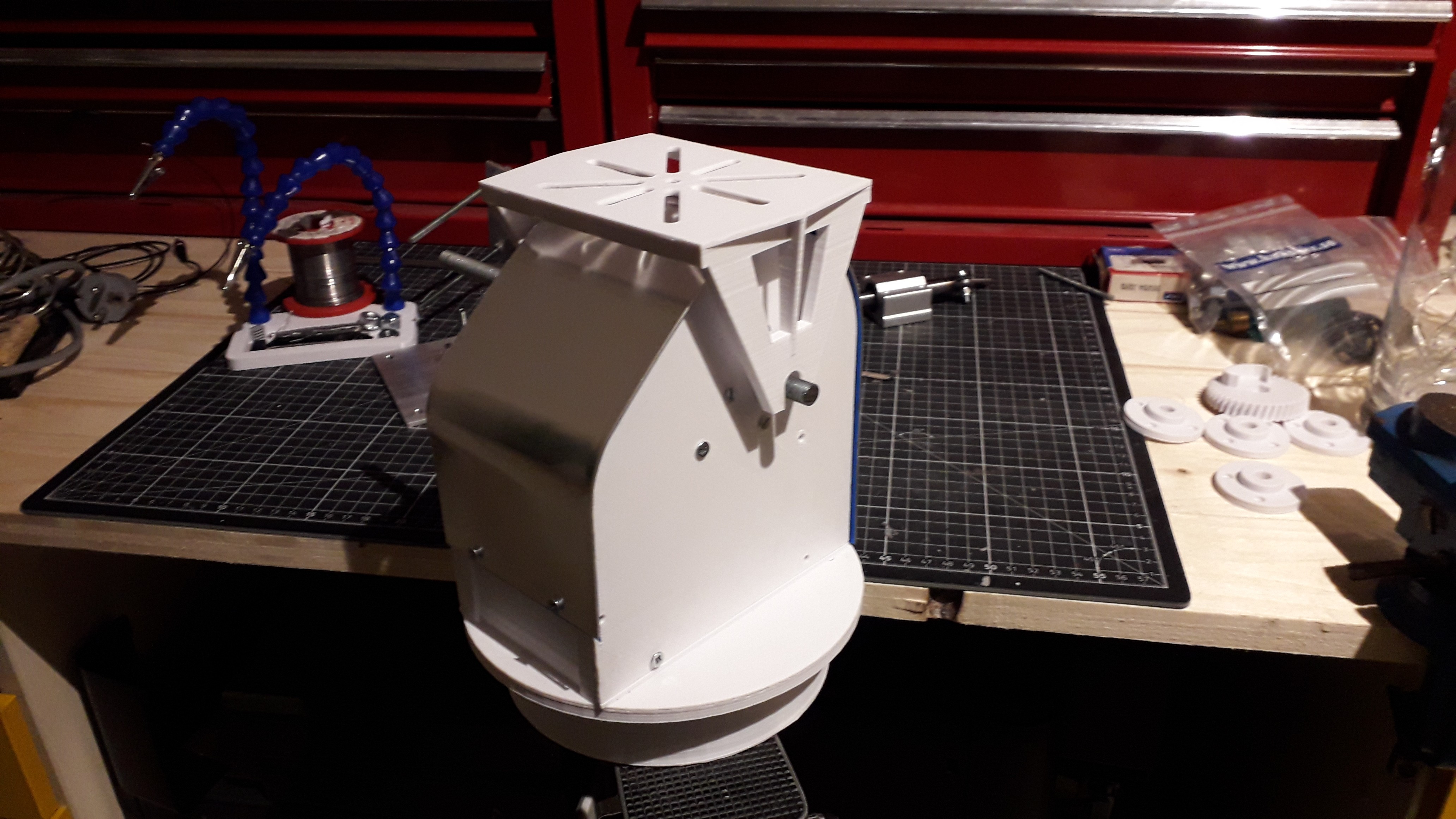

Prototype get its casing

01/09/2021 at 16:35 • 0 commentsNow all the mechanicals for the first prototype is finished, perhaps just a slab of black paint on the top aluminium cover.

Also DHL sent me a notice that the PCBs probably will arrive after the weekend, so I can start testing out the software. That is IF the circuit boards work as intended of course... *fingers crossed*

![]()

-

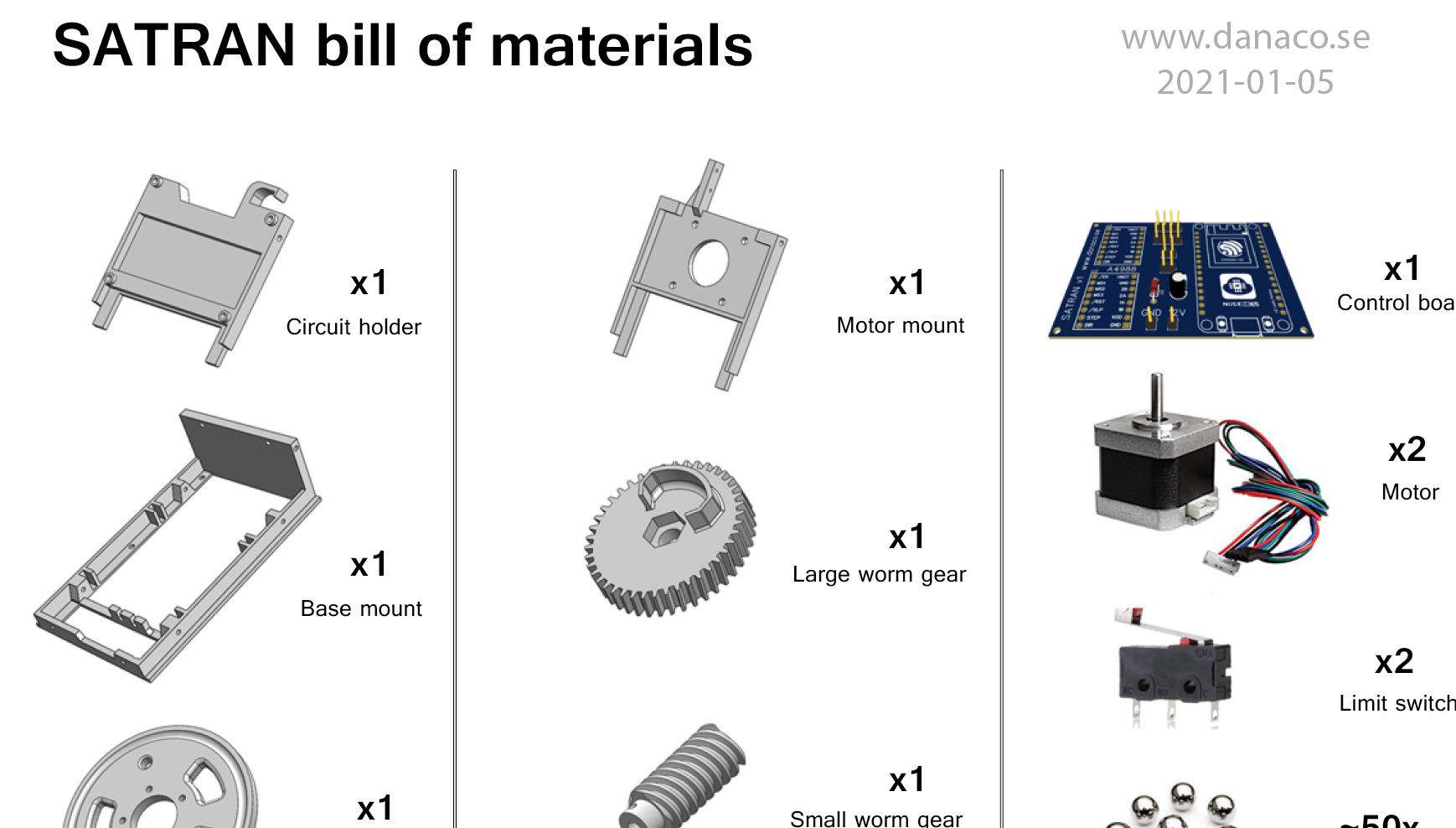

Parts list, IKEA-style

01/07/2021 at 14:01 • 0 commentsEvery kit needs a great bill of materials so you can check that you've got all the parts you need. The first draft of my BOM is now finished, but it's possible the final MK1 release will have some edits before launch.

![]()

You can find the full BOM as a pdf in the project files or on www.danaco.se

SATRAN - Satellite Tracking Antenna

Wifi-controlled, azimuth/elevation antenna rotator.

Daniel Nikolajsen

Daniel Nikolajsen