It's surprising how little 3D printer owners document how their overpriced addons work. The 3D printing industry is like the mafia where everyone wants to sell an addon, but no-one wants to reveal what's inside & it's priced like it's made of gold. It might be like that because 3D printer owners can print their own copy of whatever is being sold, so sellers have to be extra cautious about revealing anything.

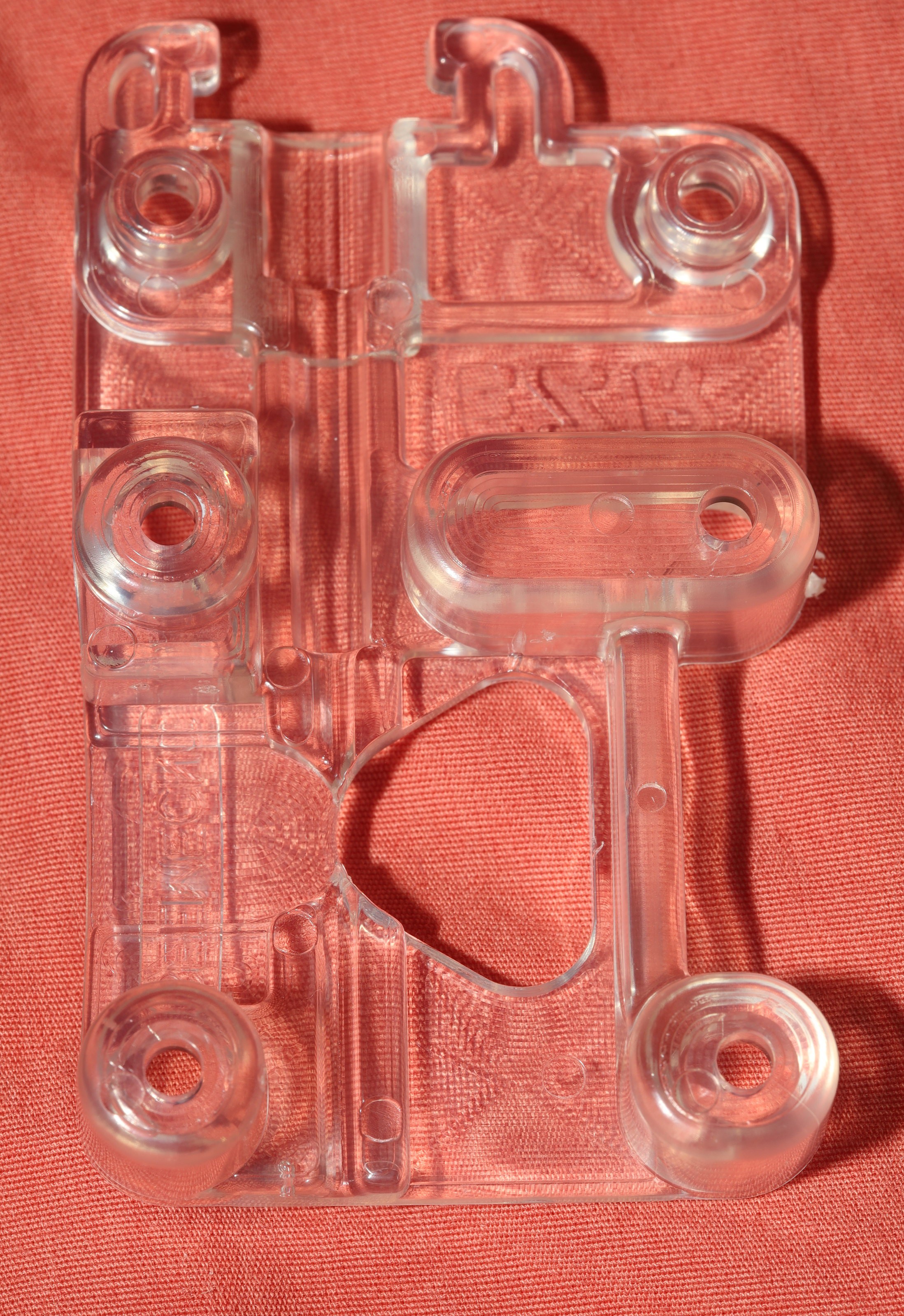

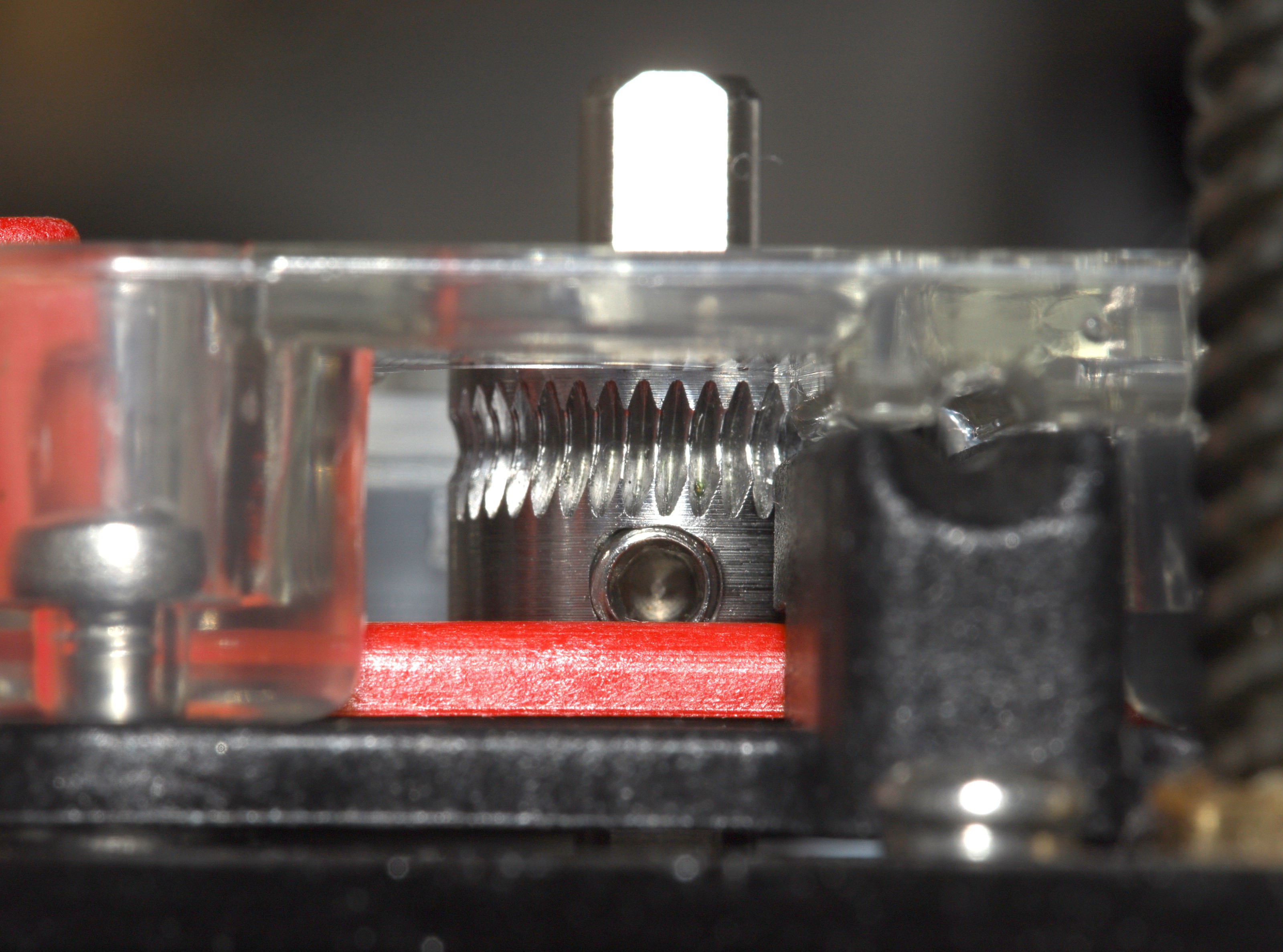

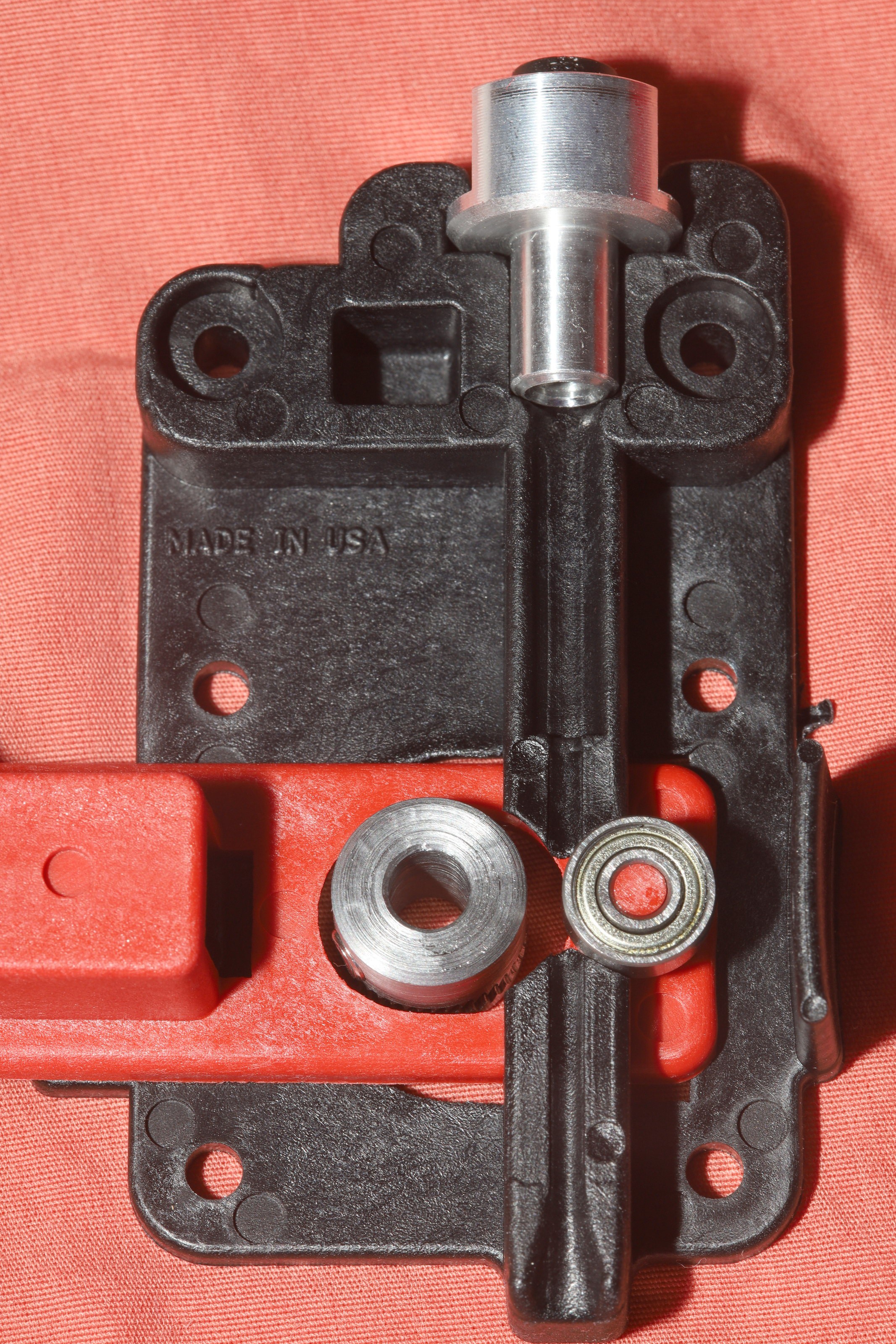

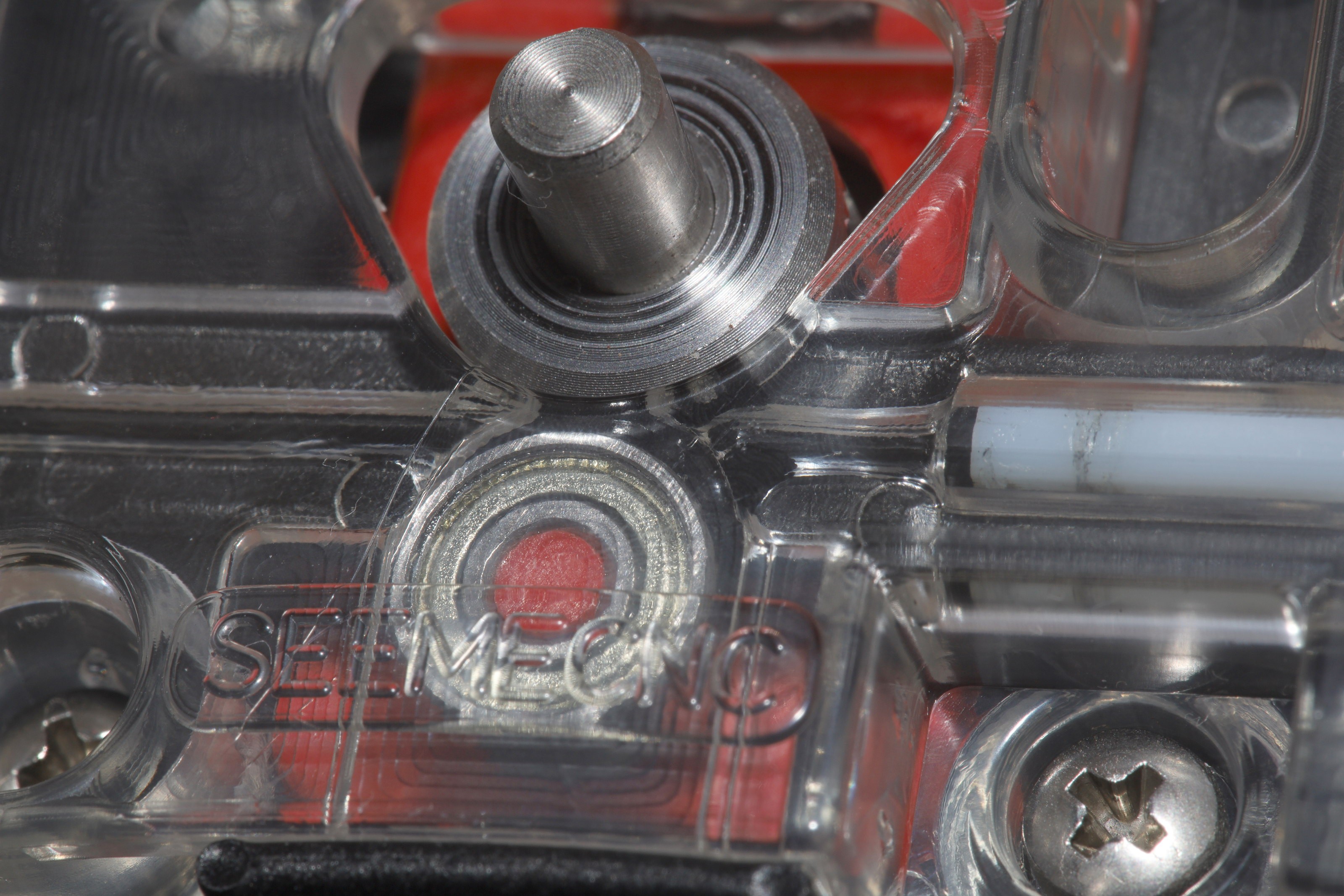

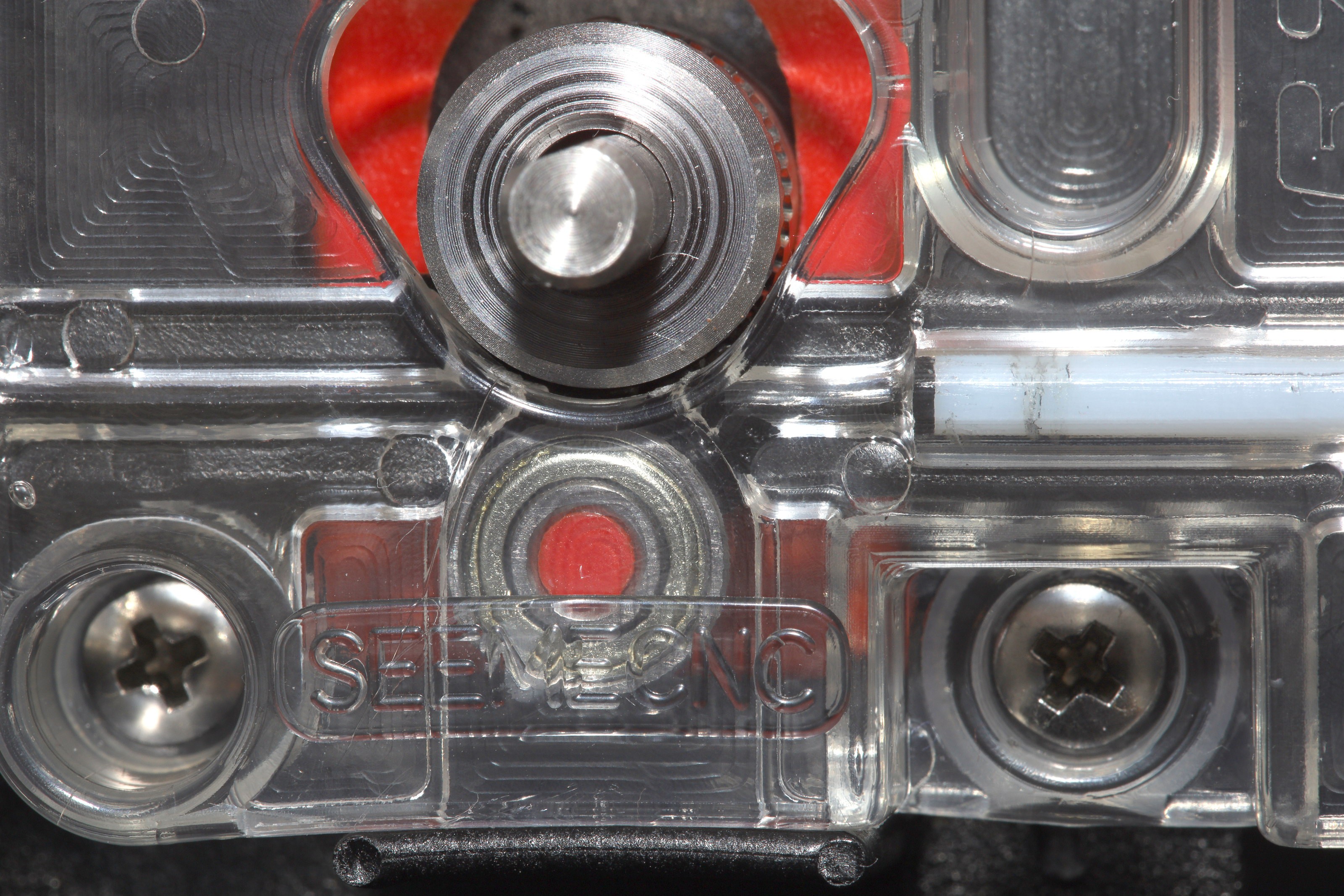

The lion kingdom's EZR struder gave no material improvement in printing TPU. Its only advantage was a knob for manually turning the extruder, which always falls off. It didn't work with the softest TPU which was 1.7mm. It only worked with a harder TPU which was 1.8mm:

https://www.amazon.com/gp/product/B08KT5RZMP/

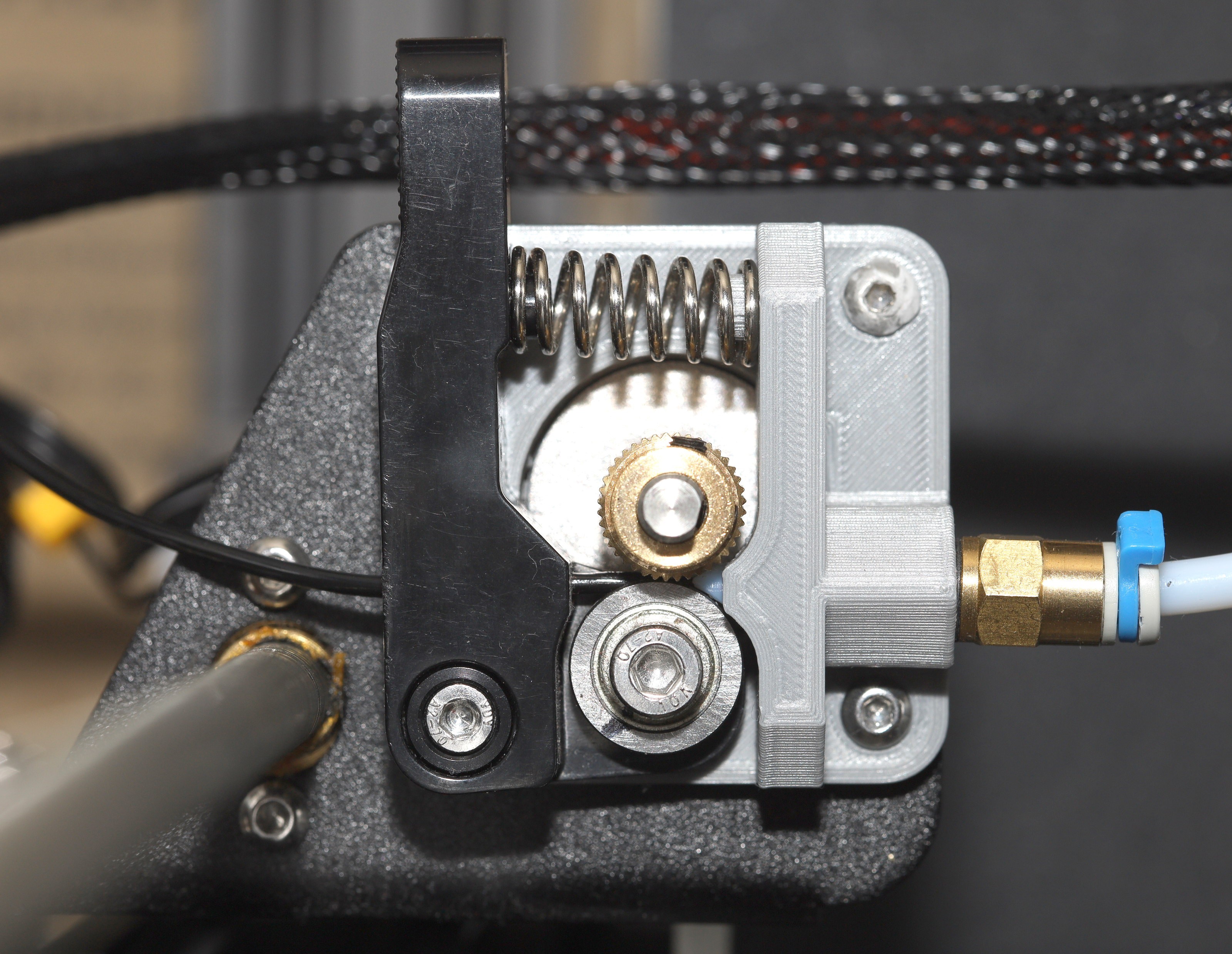

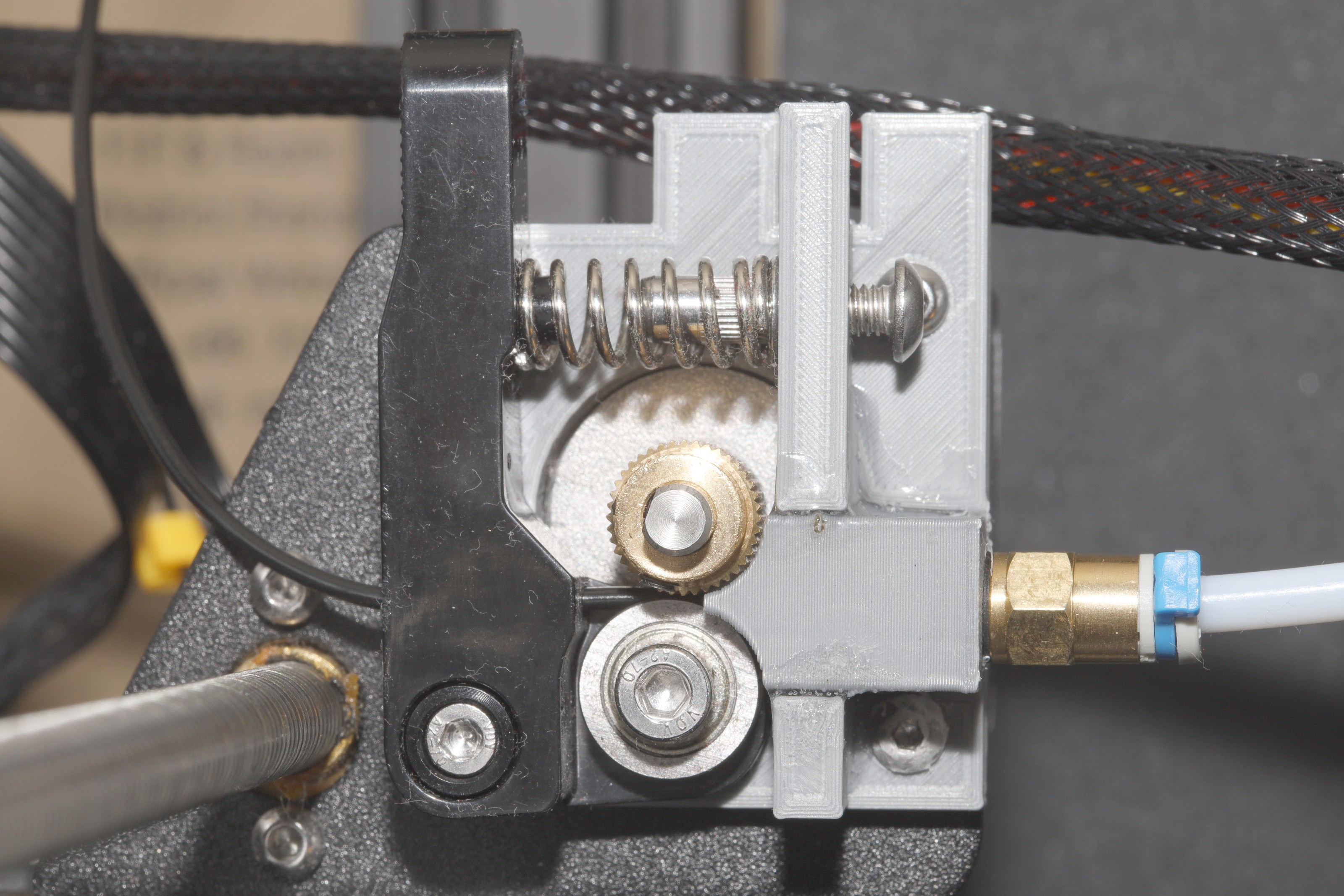

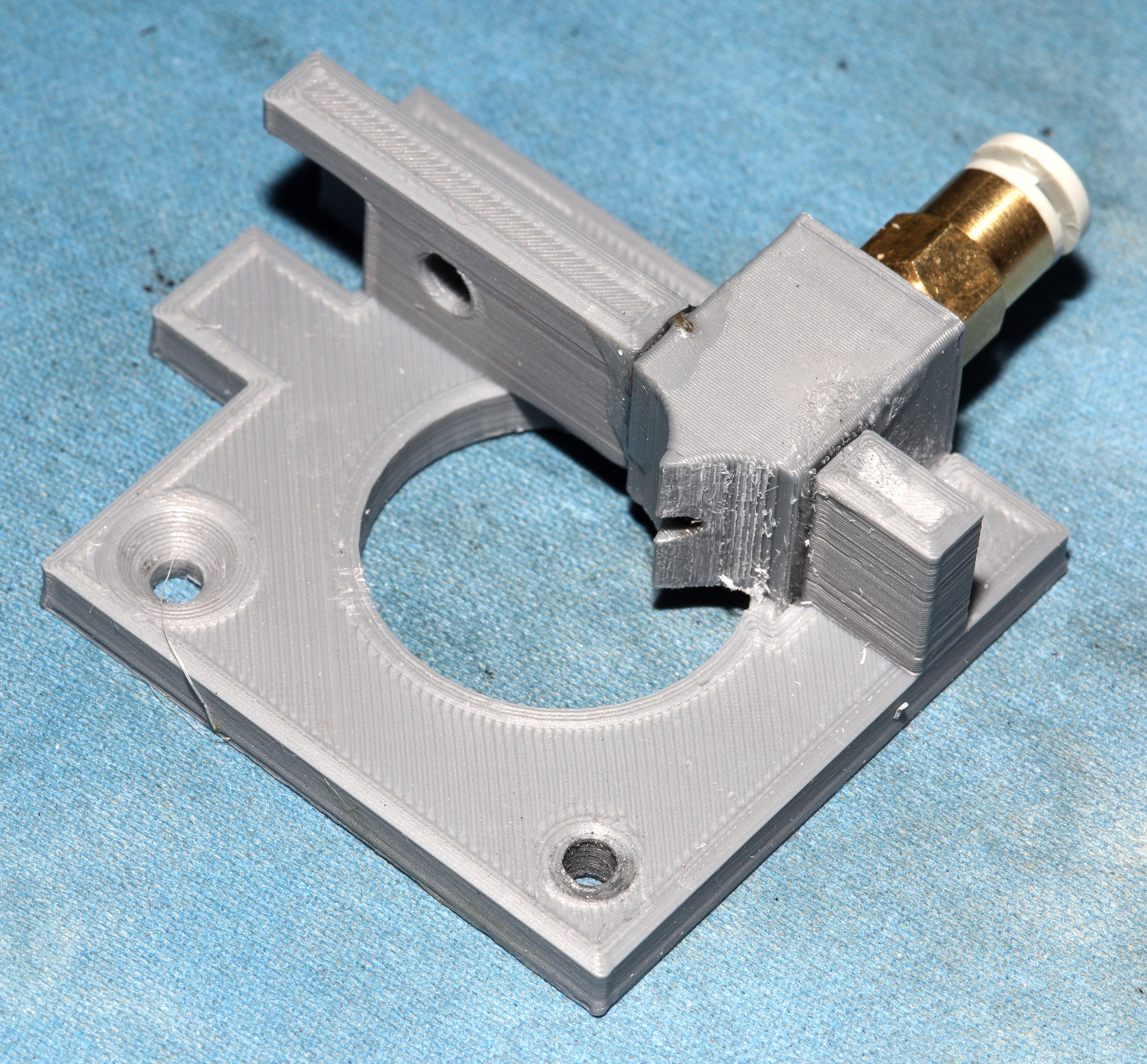

The more constrained path isn't all that constrained & similar results can be obtained by printing an extruder. The best results may come from a bondtech extruder.

Before the EZR, the lion kingdom printed some constrained extruder paths.

There was using a piece of PTFE to extend the constrained path.

There was also printing a complete constrained path & grinding it down to fit between the idler pulley.

The lion kingdom has found a similar lack of teardowns when embarking on automatic bed leveling. The BLtouch/3Dtouch is similarly overpriced.

lion mclionhead

lion mclionhead

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.