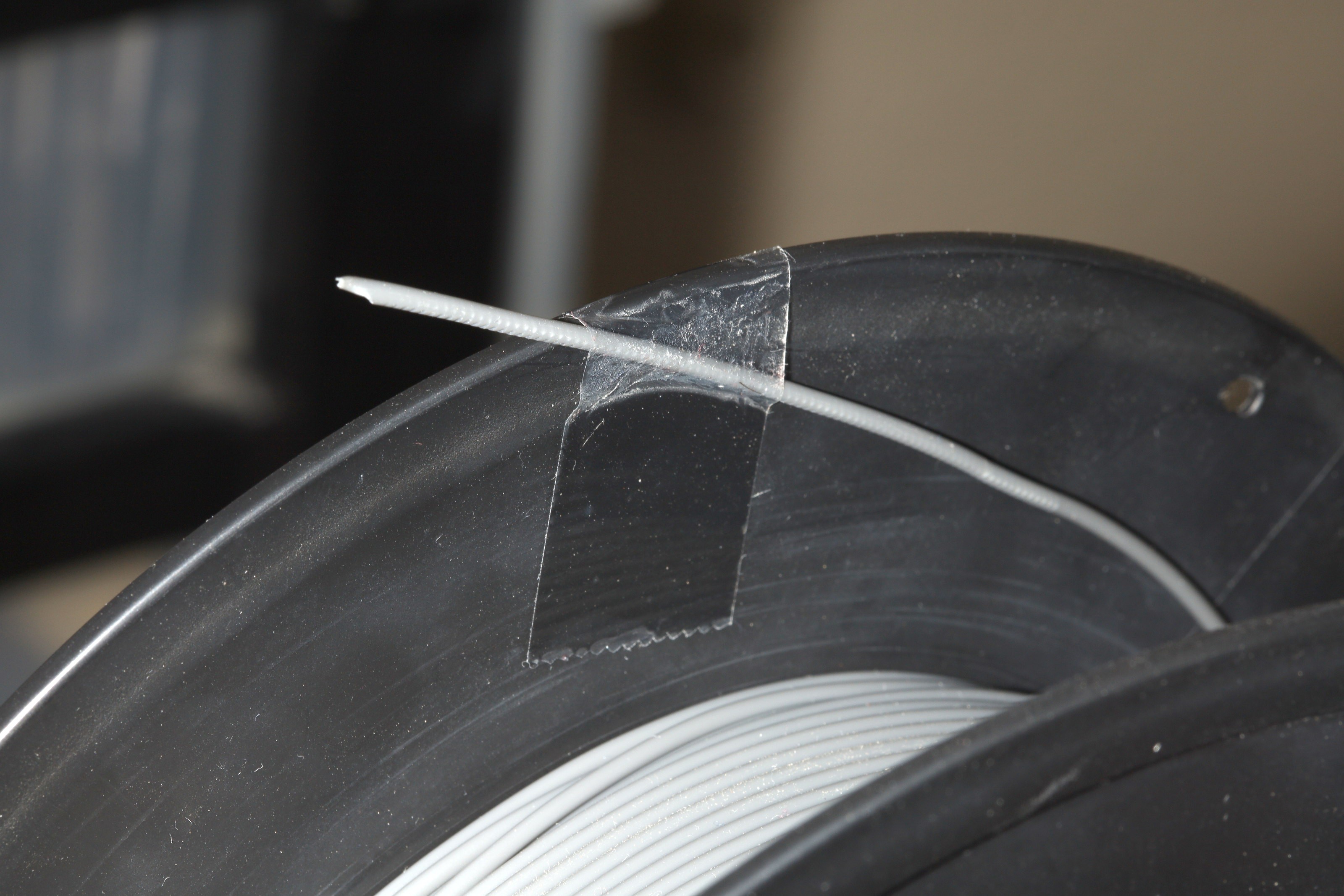

The bowden extruder stopped extruding partway through a print. The reason was

scotch tape being used to keep the filament untangled. It deposited adhesive on the filament which got in the bowden tube. It pressed through the nozzle easily. It pressed through the extruder easily. It didn't press through the bowden tube anymore. Retiring the bowden tube was believed to be the best strategy. The lion kingdom has now spent as much in upgrades as a new printer.

Direct drive extruder: $40

EZR struder: $40

3D Touch bed leveling: $20

Copper heating block: $15

Metal hot end: $15

Glass bed: $15

Magnetic bed: $15

Nozzle assortment: $15

------------------------------------------------------------------------------------------------------

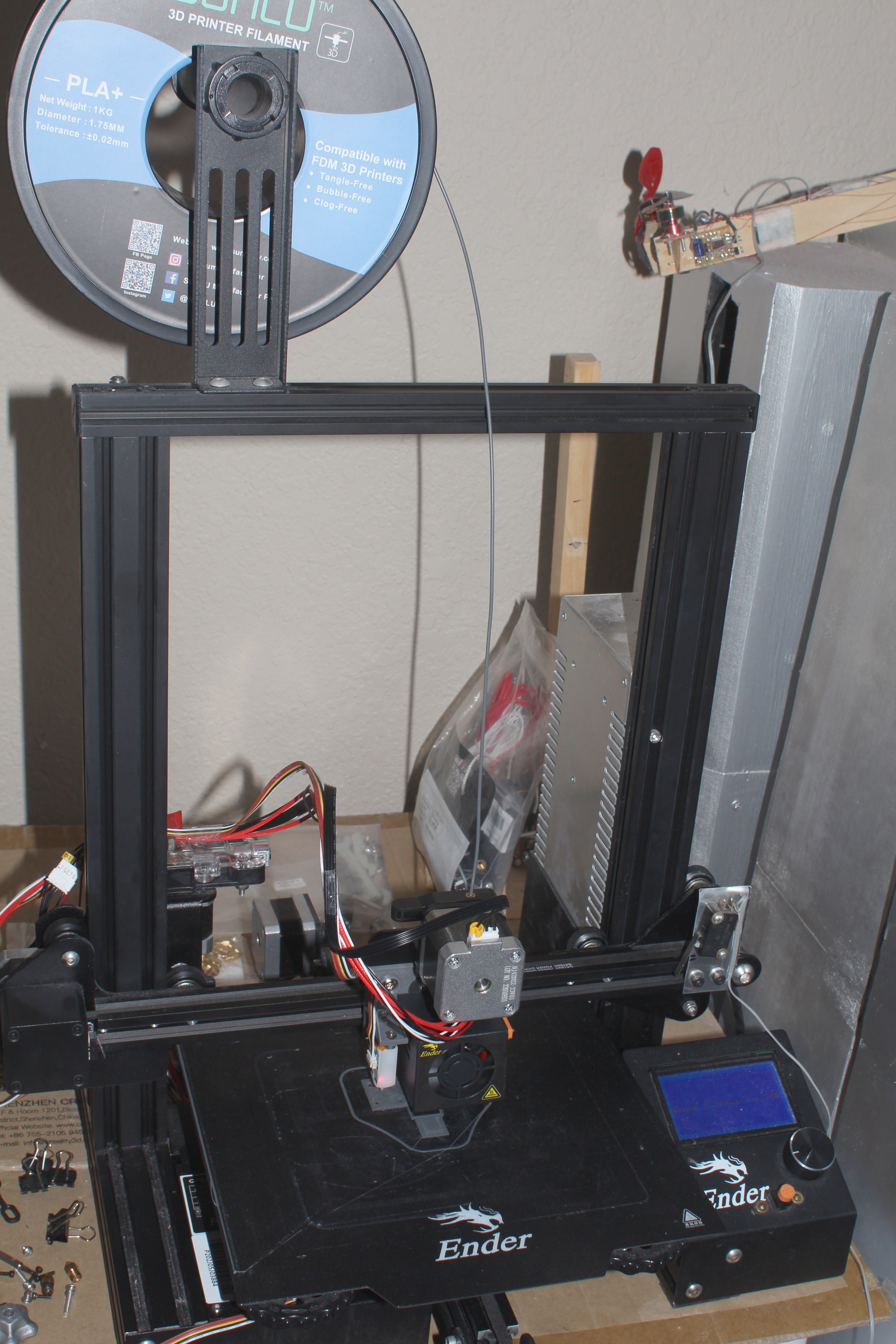

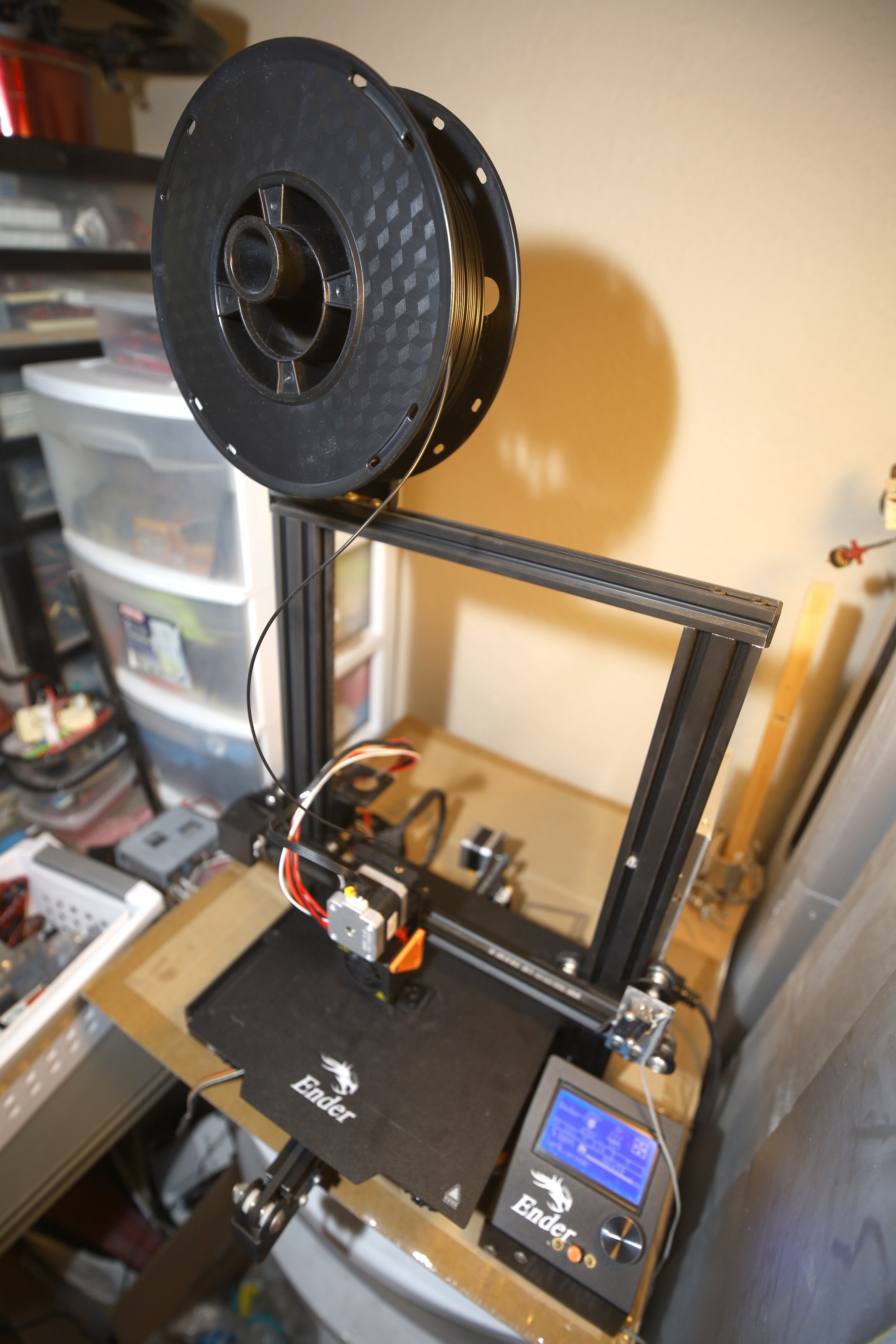

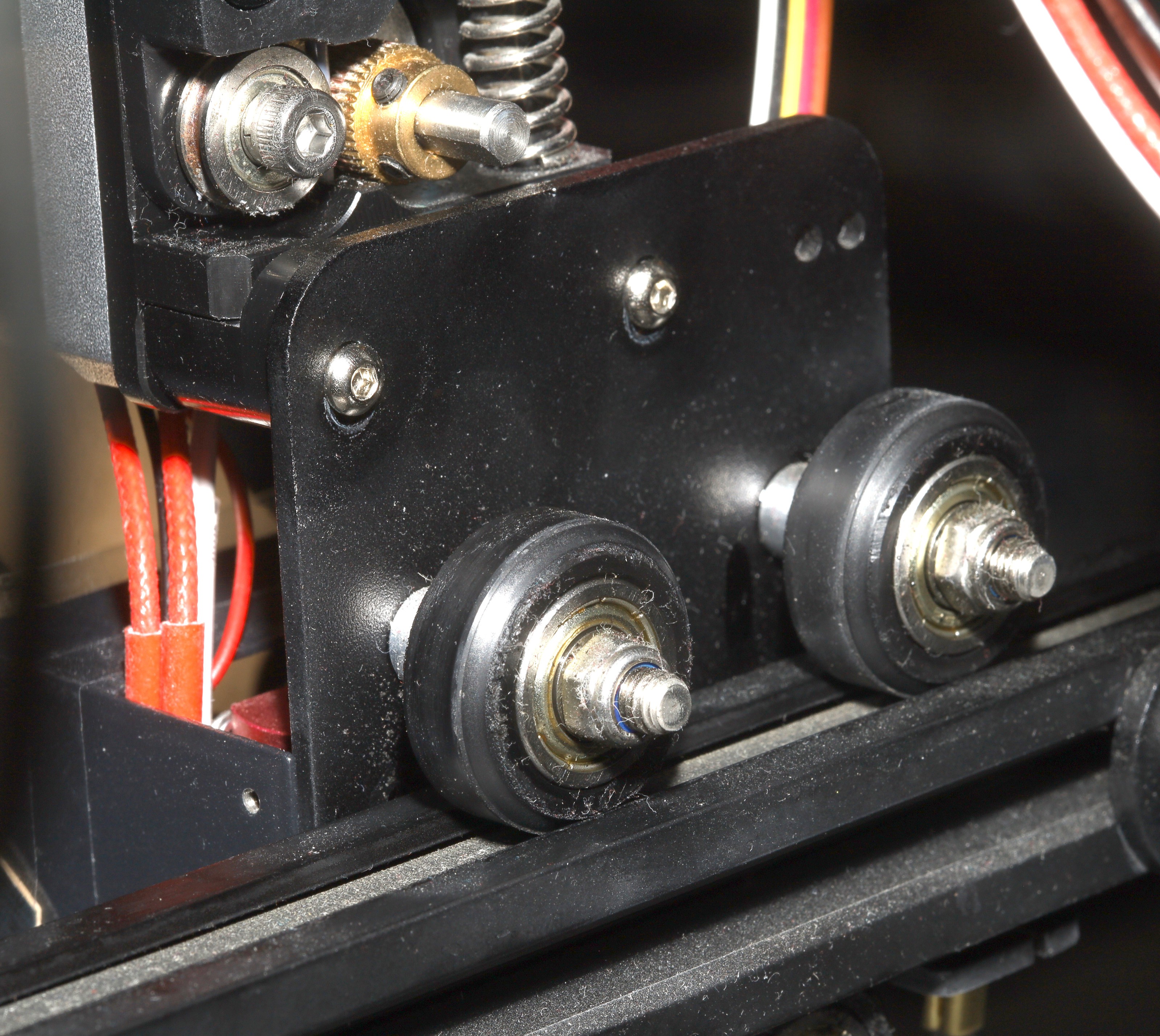

The latest replacement was the Creality direct drive

https://www.amazon.com/dp/B08J7N2LNL

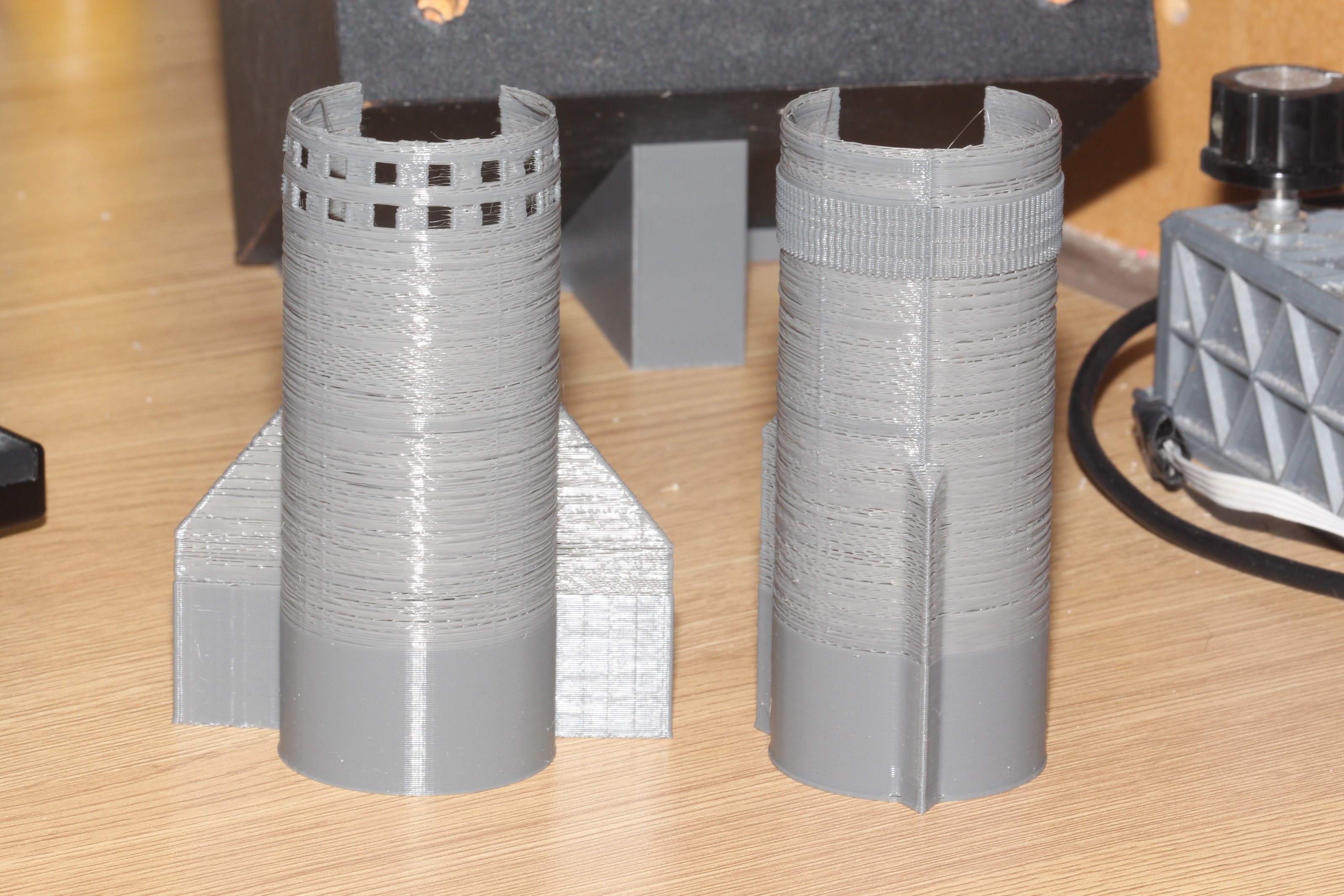

It contained a completely new hot end, fans, cables. It was a lot of work to install. They say it can be easily swapped with the bowden extruder, but lions say fuggedaboutit. The stock creality gear section was back. The X axis then sagged to the right. New parts had a slight tilt to the left but at least it printed again. If right angles are really required, the easiest solution is to hack the G code rather than try to keep the X axis level.

The filament has to go in front & unroll sideways. This is distinctly missing from the sales pitches for prusa MK III's & ball bearing filament rolls.

It successfully overcame the problem that killed the bowden tube, whether or not it really was friction in the tube. The lion kingdom has now lived through the dual gear craze, the EZR struder craze, & the direct drive craze. Will it print the unprintable Matterhackers PRO TPU from 2 years ago?

It did print the matterhackers Pro TPU even without a dual gear or a constrained path. It still ran only at 20mm/s. An important lesson is not throwing away filament that won't print. It might print in the future. This filament was much softer than the tried & true filament, but it was twice the price & would require redesigning the tires.

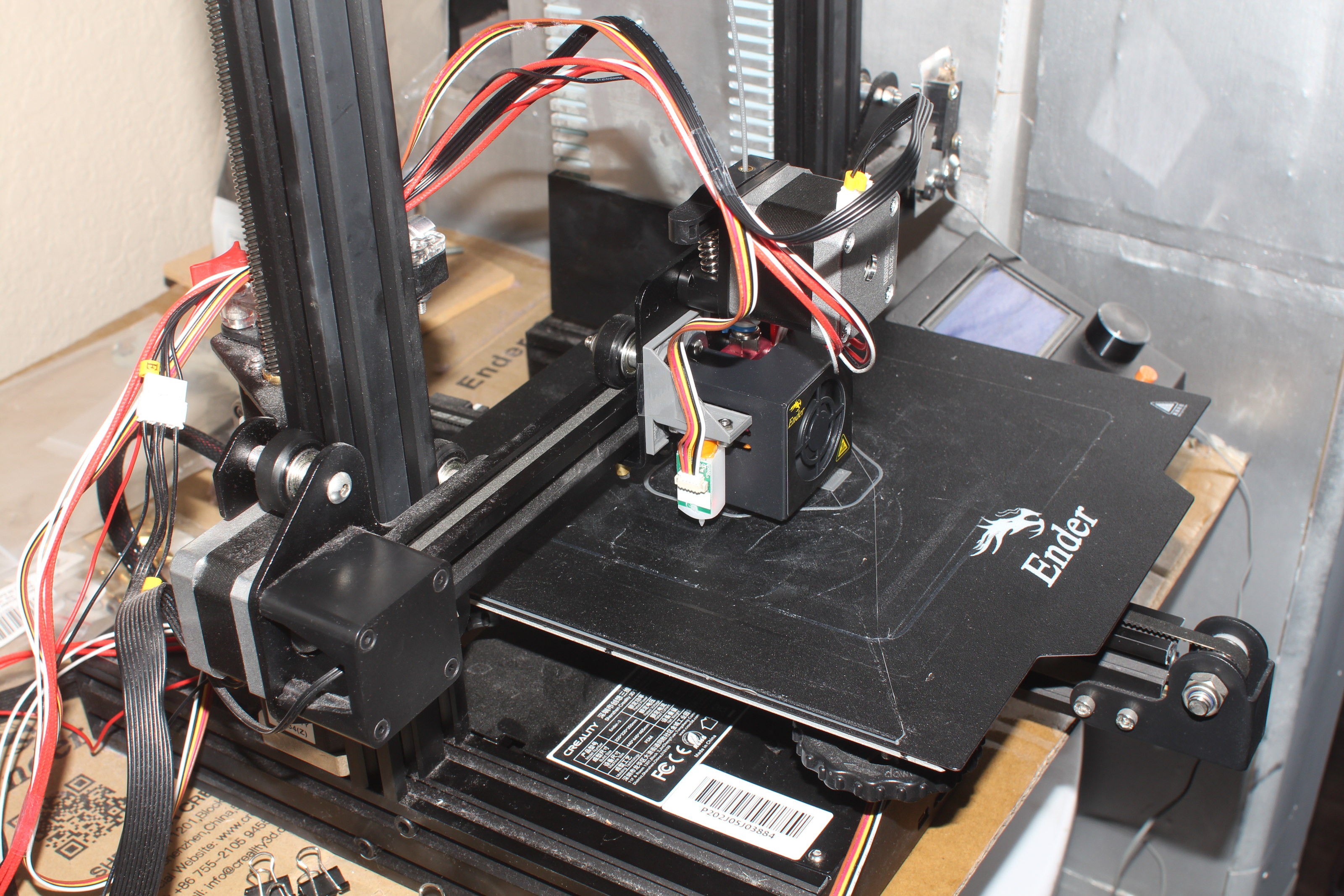

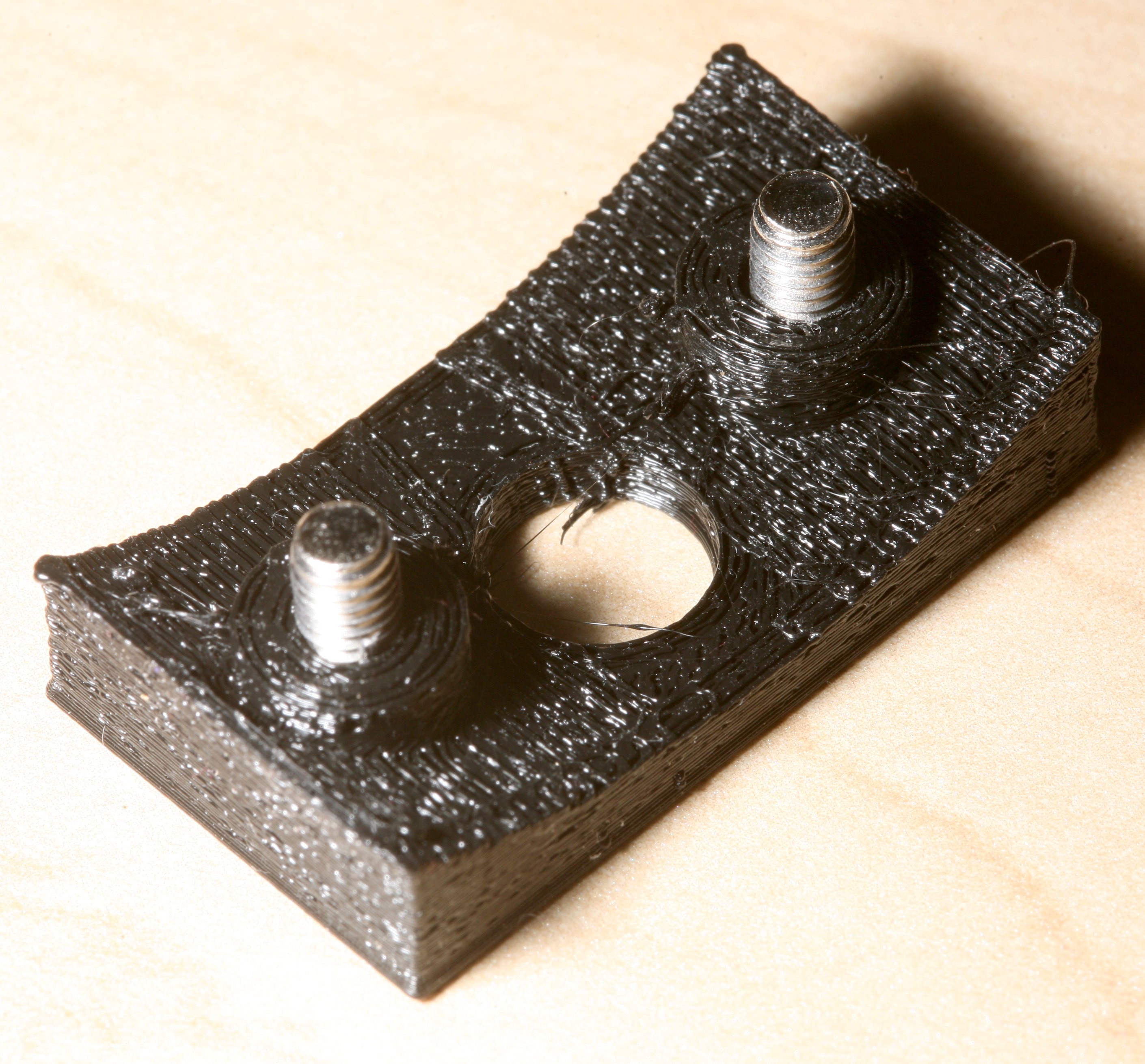

After many months of direct extruding, it was the lion kingdom's turn to deal with a broken PTFE tube clamper. These never release.

Fortunately, the direct extruder doesn't need it.

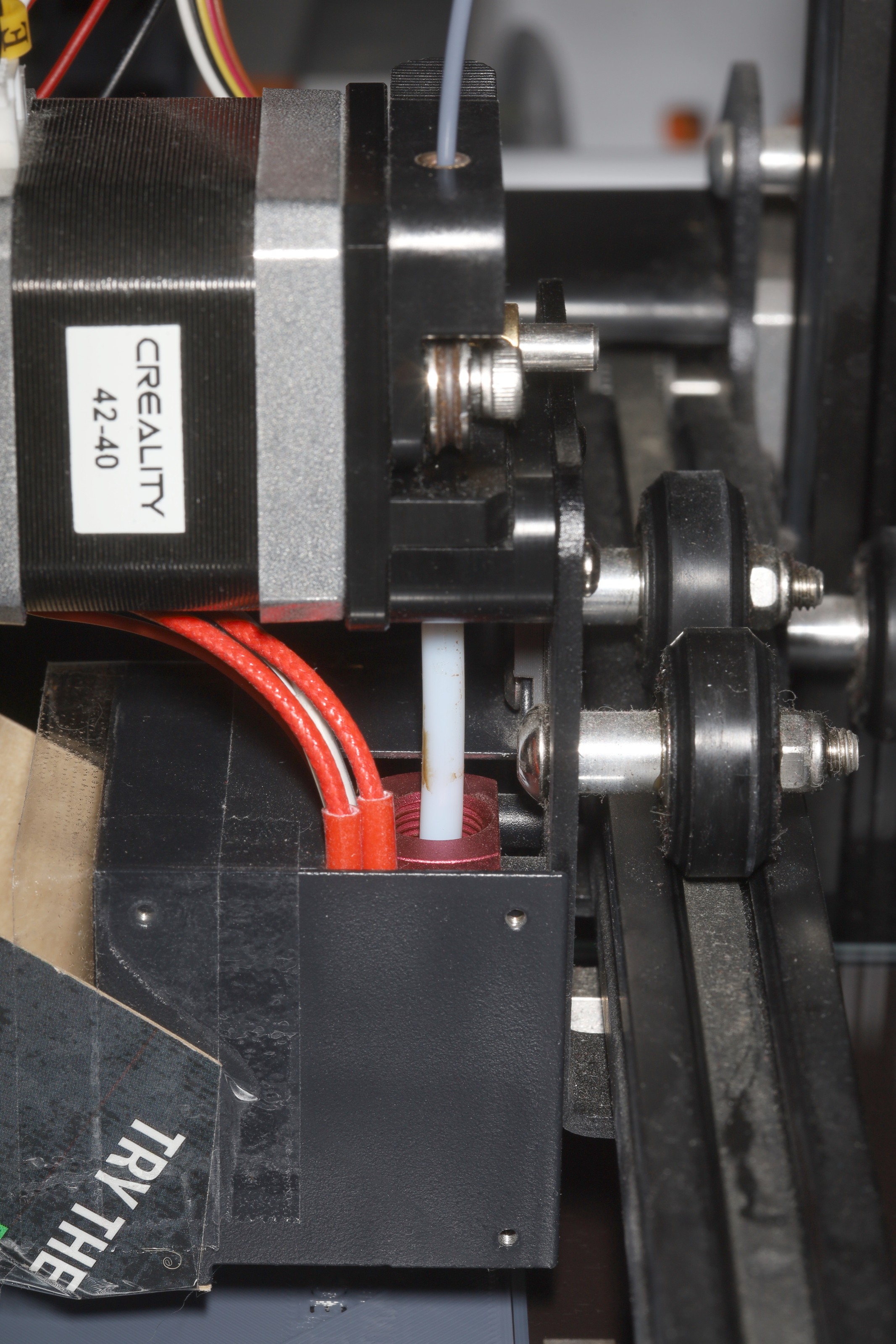

Just measure out enough PTFE tube to press between the nozzle & struder.

There's enough wiggle room for the tube length to be a few mm off.

The tube after many months of high temperature printing was carbonized but still intact. The internet recommends capricorn tube.

lion mclionhead

lion mclionhead

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.