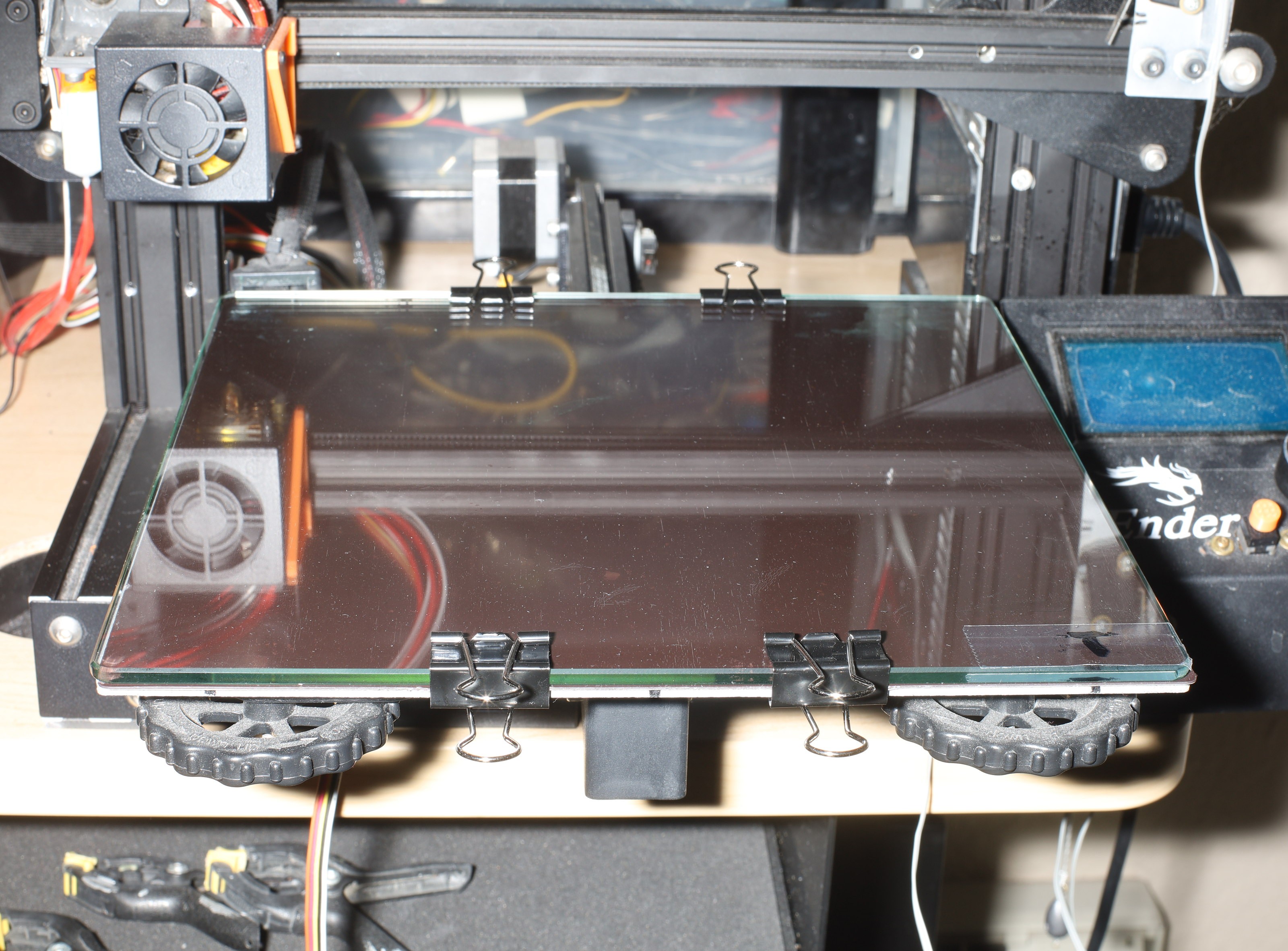

The rest of the world moved on to steel, but the lion kingdom recently had good results with old fashioned glass. The trick with glass is to wash 1 side with dishwashing soap & dry it with paper towels so no oil or wax is present.

This one has a marker to indicate which side has been cleaned.

Clip it in the middle & it stays more level than the machine bed. It has been level enough to not need auto leveling. Heat it to 55C for PLA. TPU doesn't benefit from heating but does require a glue stick. The finish isn't as shiny with the glue stick. TPU can be printed without the glue stick but it warps.

It adheres PLA better than TPU. PLA parts can only be removed by dunking in cold water. It's not known if cold water can shatter the glass. The results are very shiny printouts.

To avoid the hassle of dishwashing soap & drying, buildtak still has a role where shine isn't required. The shine doesn't last, since PLA is very soft. It's most long lived on cosmetic surfaces.

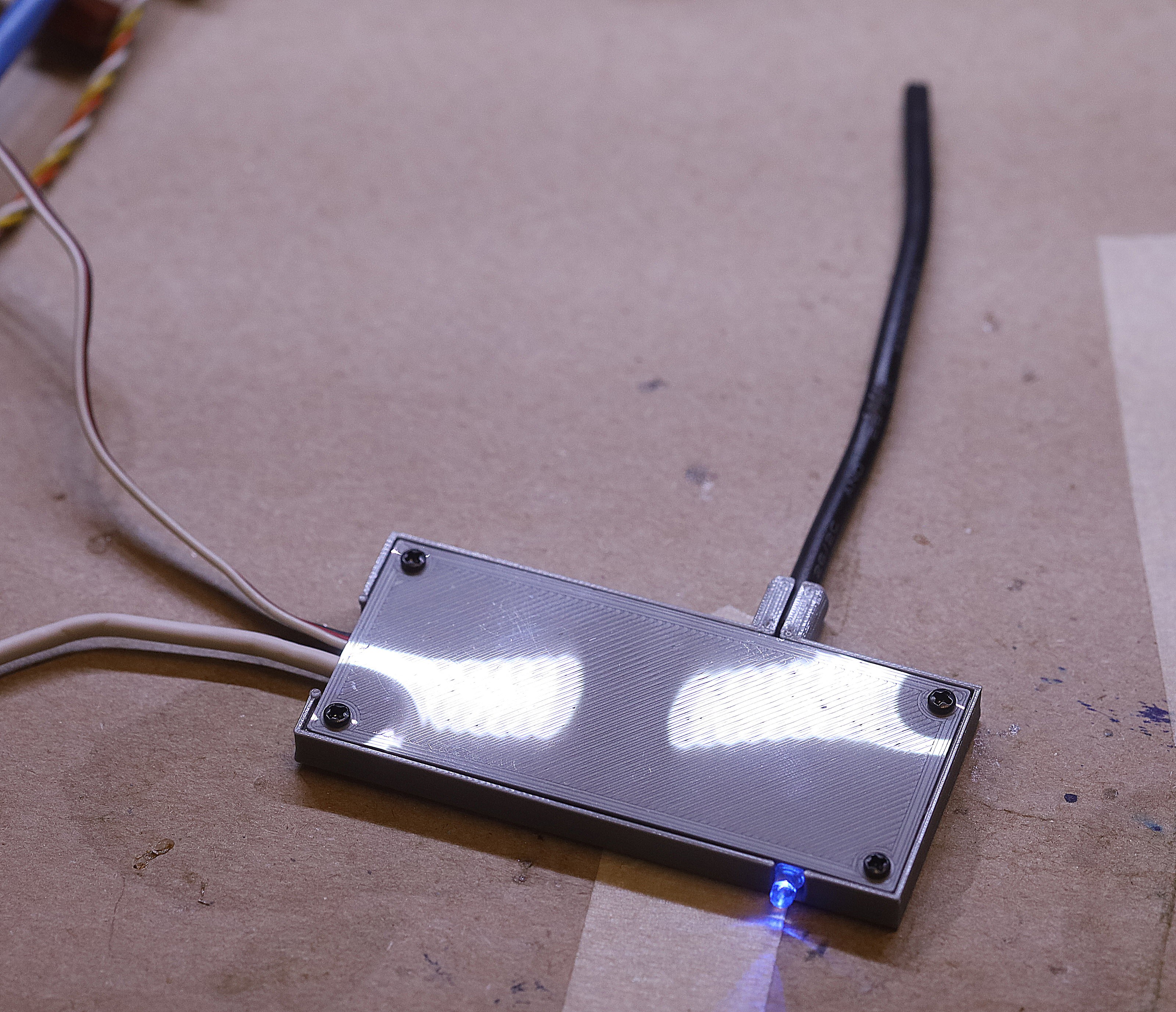

To apply hot glue, the opposite side must be on glass or it'll conform to whatever surface it's on.

lion mclionhead

lion mclionhead

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.