I've been enjoying using my TI-58 and TI-59 calculators, and the vastly increased run time before recharging is required. The only drawback is that I have to be very careful when removing or inserting the pack to avoid breaking the fragile retention tab on the FDM 3D printed housing. The reason for this fragility is that the best orientation to print the housing is exactly the wrong orientation to print a robust flexible retention tab.

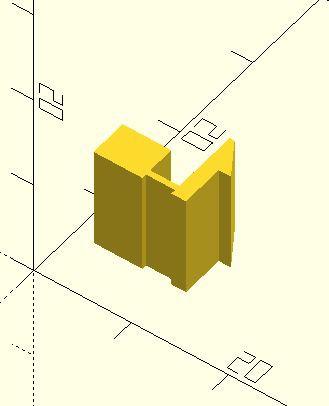

I finally "rolled up my sleeves" and did some more work on this. I started by isolating the latch tab from the housing model and rotating it to the correct printing orientation:

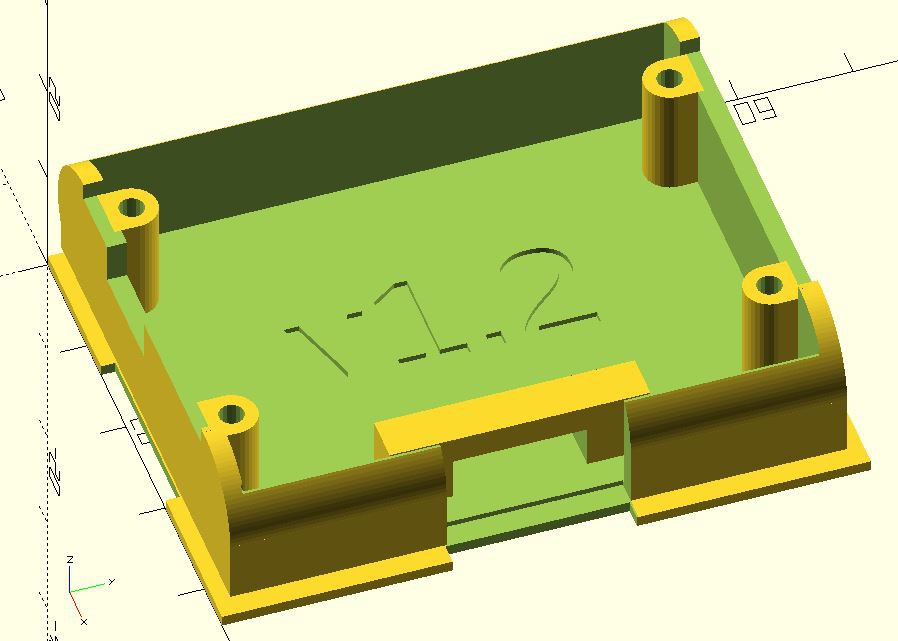

I then printed several of these, with varying beam thicknesses (0.5mm, 0.6mm, 0.7mm, 0.8mm) from PLA+ which results in a bit nicer overall finish. This orientation puts the axis of bending around the Z axis, which is exactly how a FDM item should be oriented to survive bending cycles. The amount of flex of the 0.6mm beam variant seemed pretty good, so the next step was merely to adapt the rest of the holder model to accept the large "stub" of the tab and try it out:

Of course, when slicing this model, supports are required to hold up the 'bridge' of the socket. It actually took a couple of tries to get the socket part to be strong enough and have sufficient clearance to mate with the retention tab piece. After printing, I carefully cleaned the support stuff from the inside of the socket and inserted the tab piece. The results seem to be much more robust and I feel much more confident about the longevity of this holder versus the less complicated all-in-one style.

tomcircuit

tomcircuit

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.