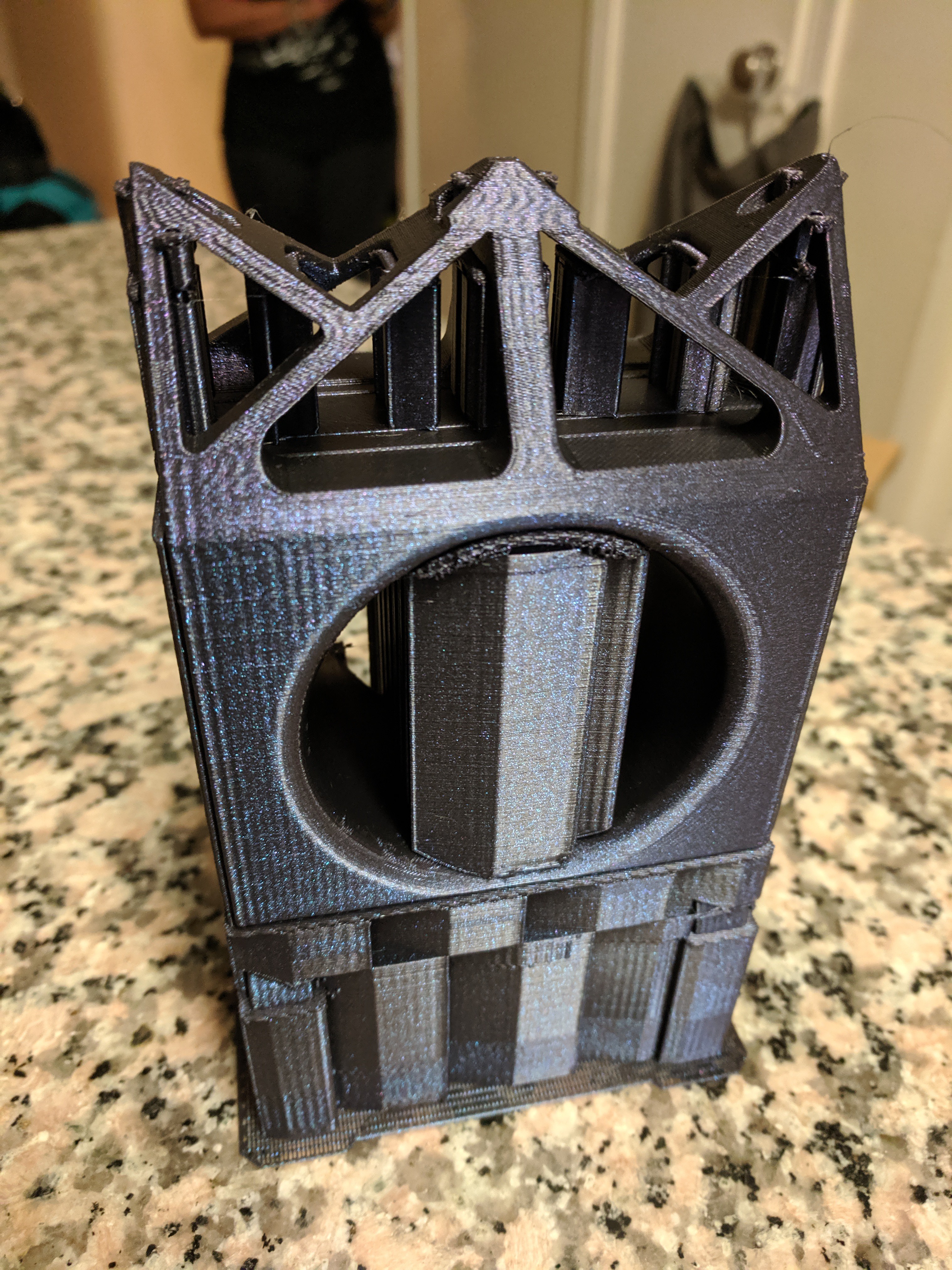

The first design was born out of urgency. After some lessons learned. I CAD'd up the foam design so that it could be 3d-printed and shared.

Limiting support material at first was a goal, but then.. well.. I totally abandoned it. I needed interfaces where I needed them, and strength where I needed it.. Oh how I wish I had the time and patience for elegance.. Well here you go.

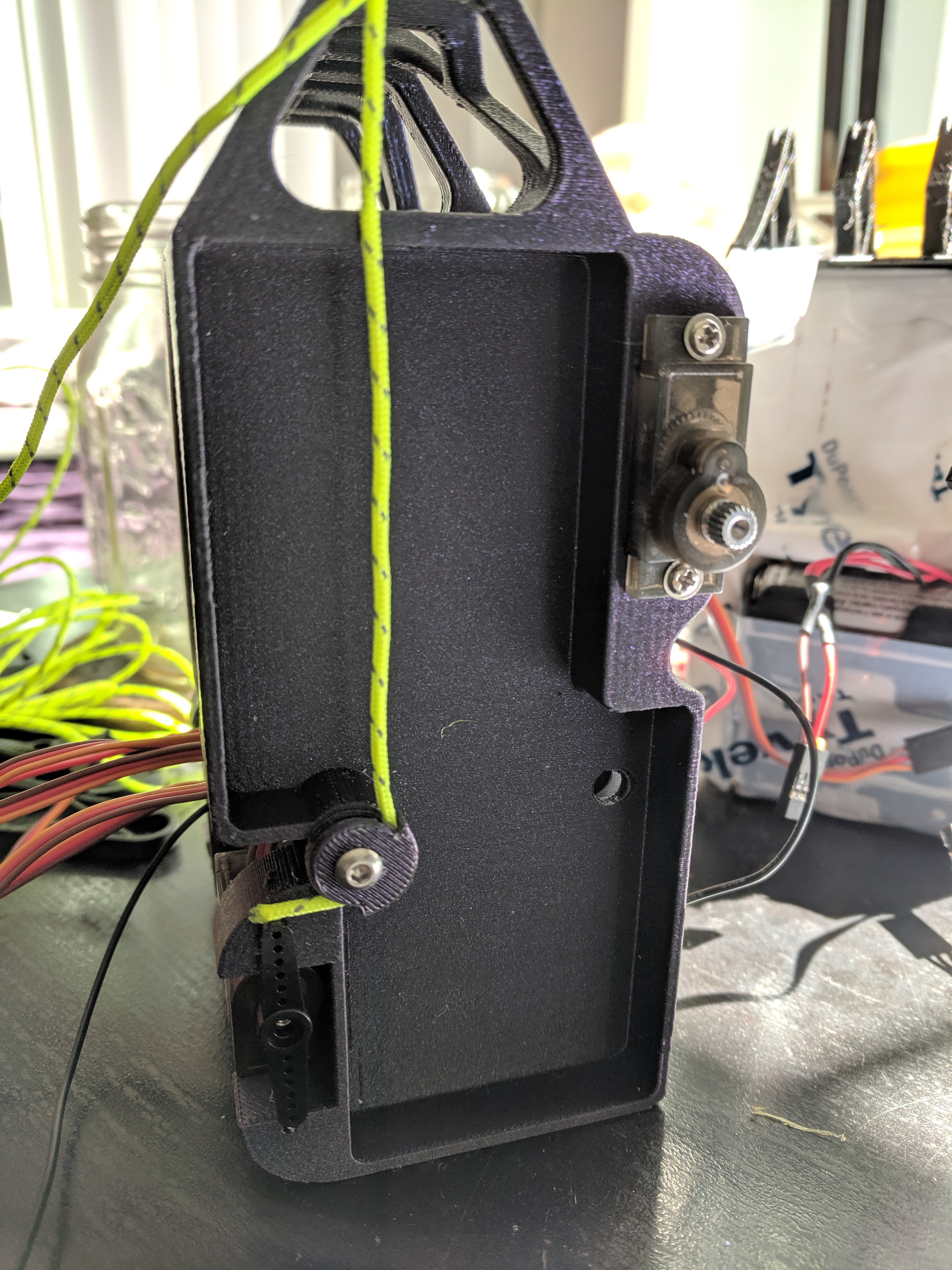

One thing I wanted to add was a speed system. This is an accelerator, that changes the angle of incidence of the wing relative to the robot pilot. The effect is that the system flies faster. The glide is reduced, but the Freedom of Movement is increased in situations with headwind. I made small pullies with even smaller bearings, why? because i tried to find tiny bearings! it was awesome.

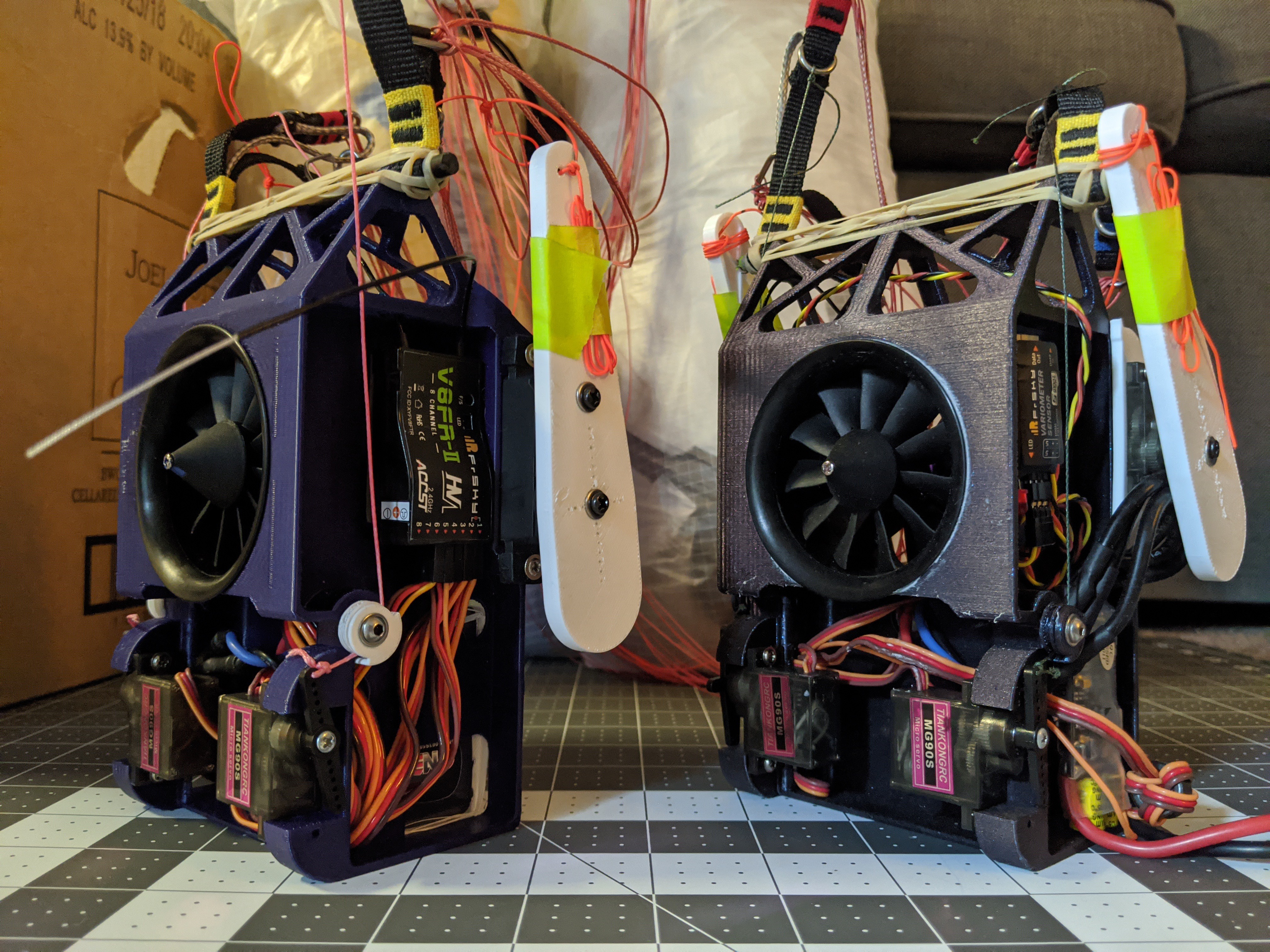

One thing that was discovered primarily due to scaling up the wings, was that when loading was increased the original 9g servos just didnt have enough torque to steer. This also was noted when flying at Pacifica, California in 20mph of wind.

More POWER! I added larger servos, but in doing so a number of issues popped up.

1. The noise was so loud because of the constraining of the airflow on the EDF

2. The control arms needed a redesign.

3. More power use.

4. there was an unexpected unplanned benefit from undersizing the servos.. In high speed high load situations.. the wing.. well wouldnt spin or stall due to input.. When flying lightly loaded this was a characteristic that was noted often. The limited torque would mean almost no displacement for the servo.. In 30mph of wind.. thats perfectly fine..

5. My issue with 4 is that its not controlled.

------

These units are to understand the wings. Not for the free flight side of things, but its not everyday that you can deploy from a balloon, or you must have a UAV or other method, building, bridge etc. I did not have these.

Speed system on the single surface, helped but also led to many frontal collapses.. In the end.. Im not sure it is the right fit. Also it was critical to not induce any torque from the speed system, or the pilot would rotate and the thrust vector would change. This could be used as an advantage, but I choose to reduce it to near zero.

The idea was to build these out to be super reliable. share with the world. Get students and universities developing the software further. Work on modes and automation, as well as fleet management, deployment and collection.

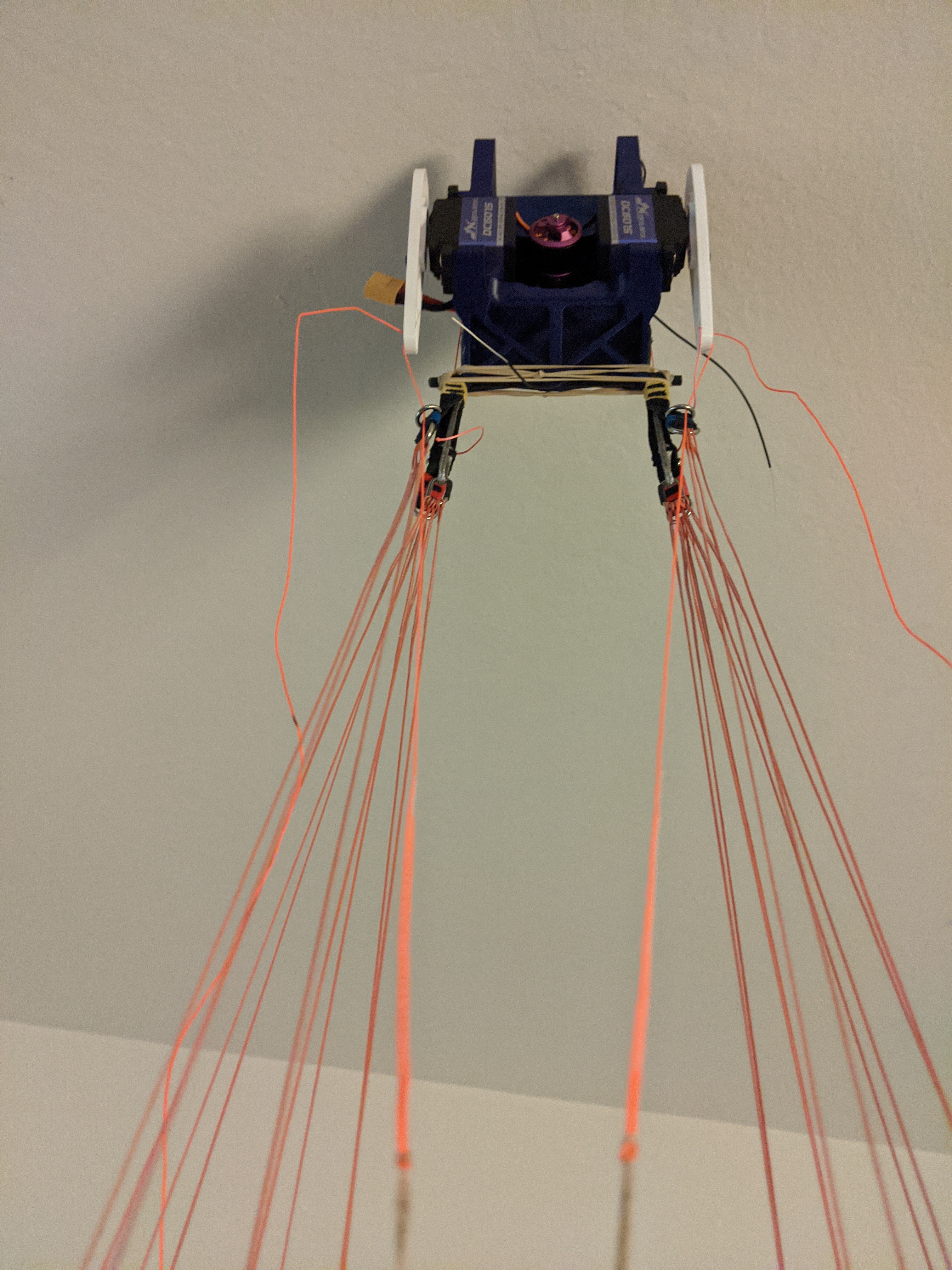

How do you create a process everyone has access to. Well. To tune the brakes. I figured I need load in some direction at minimum. So I hung the whole thing from my ceiling. This gave me a great starting point that I later adjusted.

freeflightlab

freeflightlab

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.