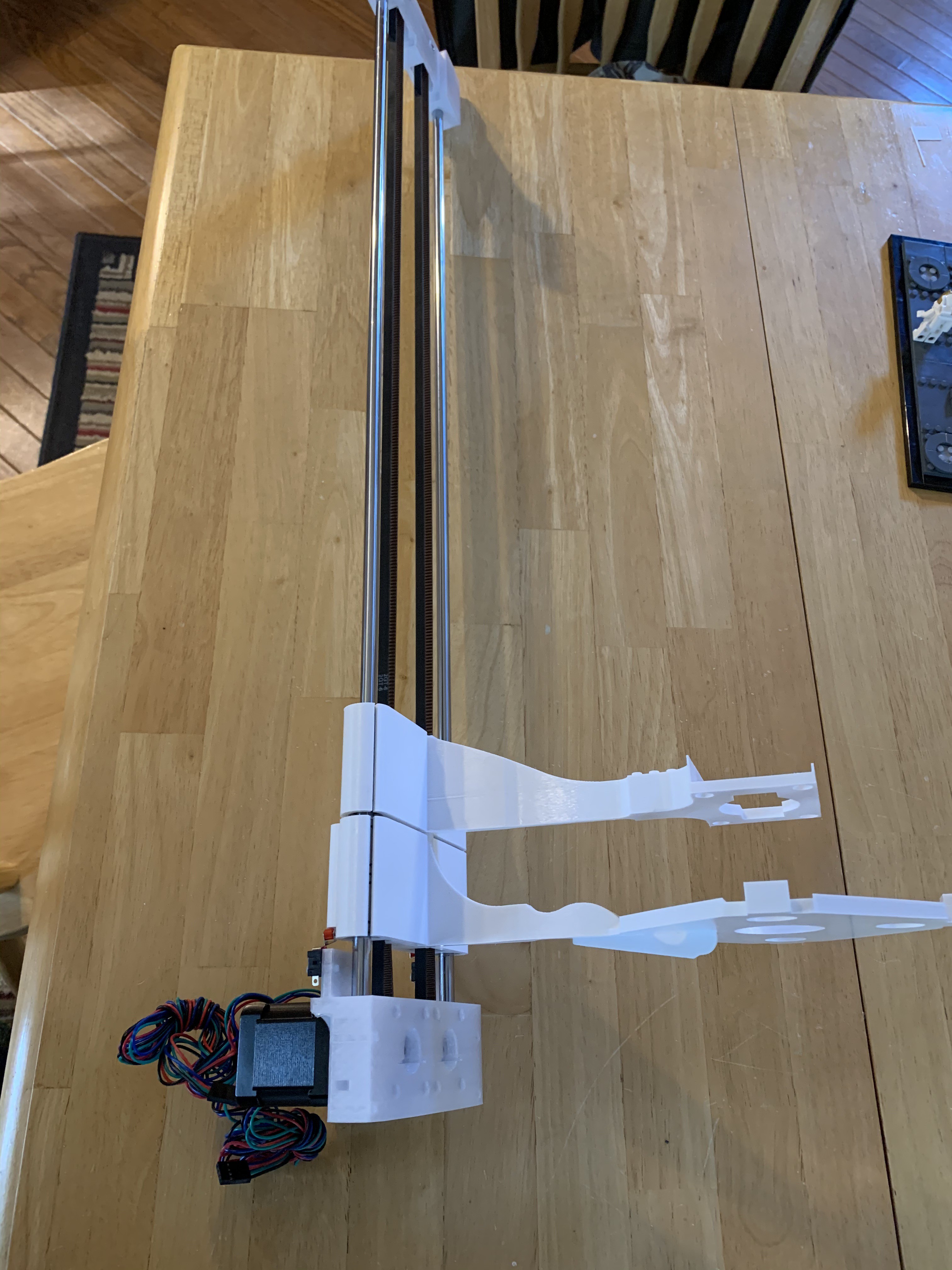

Parts finally arrived for assembly. After a few hours of 3D printing, things start to take physical shape. Everything is modeled after a 3D printer slider.

Everything fits!

A couple of 3mm bolts are used to push down on the motion rods to adjust the tension on the timing belts. Idler pulleys ride on 3mm bolts. Top and bottom rod holders are printed with PET. Ascent and descent stage parts are PLA.

Mark Howe

Mark Howe

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.