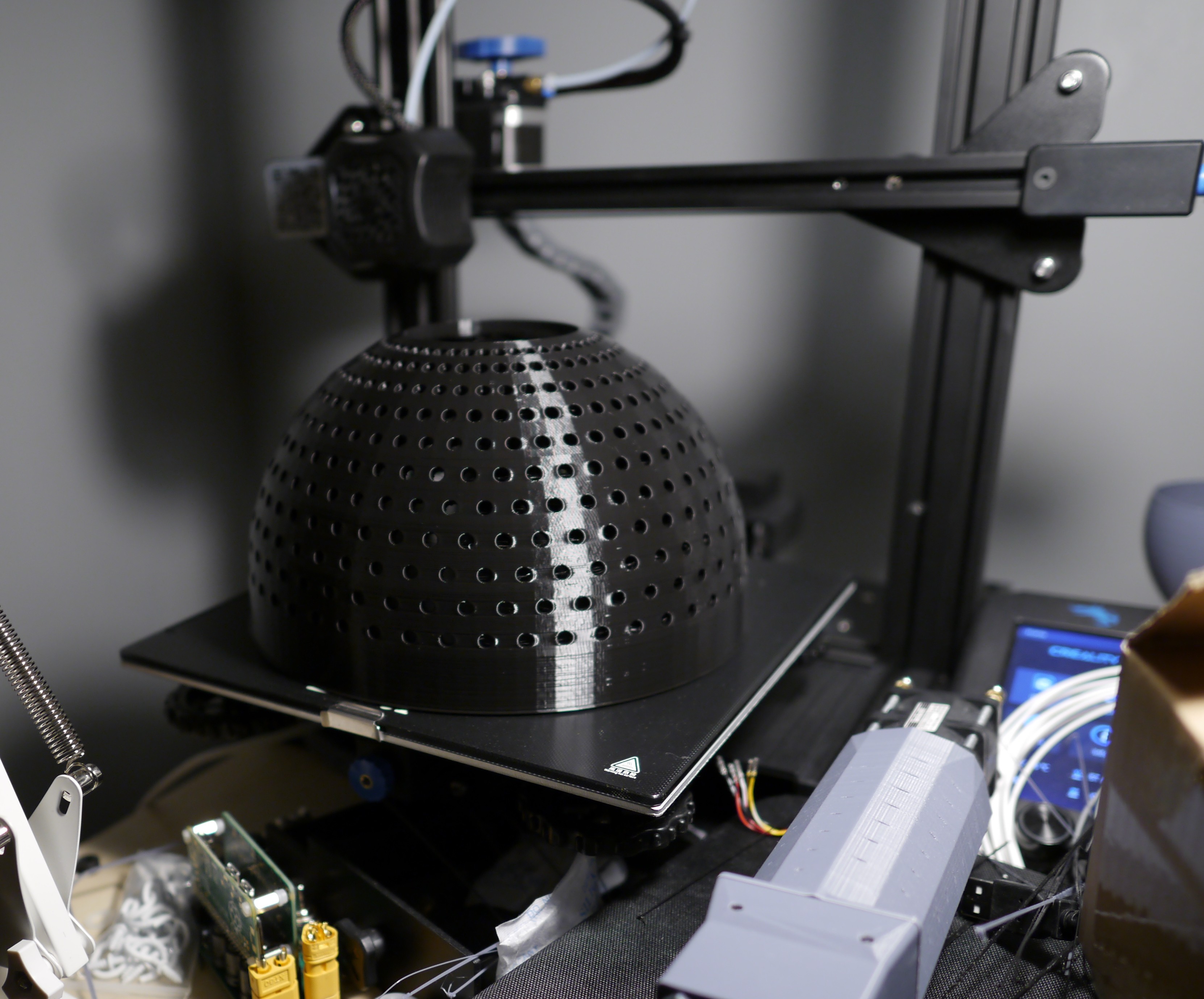

The print just completed and I wanted to make a few notes about tolerance.

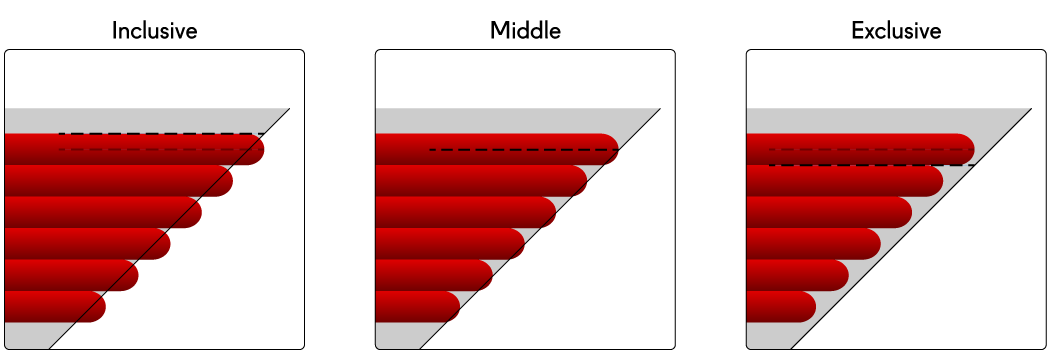

Tolerance of others lifestyles is critical for being a good person, but tolerances on 3D printed parts are not essential for being a good person. No matter what you do, mis-fitting parts are destined to print on fresh, untested settings. I designed with this in mind and tossed in a 0.2mm hole oversize. Cura also has a setting called "slicing wall tolerance" which allows for exclusive, inclusive, and middle slicing tolerances.

As you can tell, for fitting 5mm LED's through 5mm holes, I should have used exclusive tolerances. The problem is, I did and it still didn't fit. On such a large print, you can't afford layer adhesion issues, so the surefire solution to preventing that is to boost your extrusion and over-extrude by setting infill "flow" to 125% and wall flow to 110%. Unfortunately that resulted in holes that are *just* too snug.

Time to whip out the drill.

Sina Roughani

Sina Roughani

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.