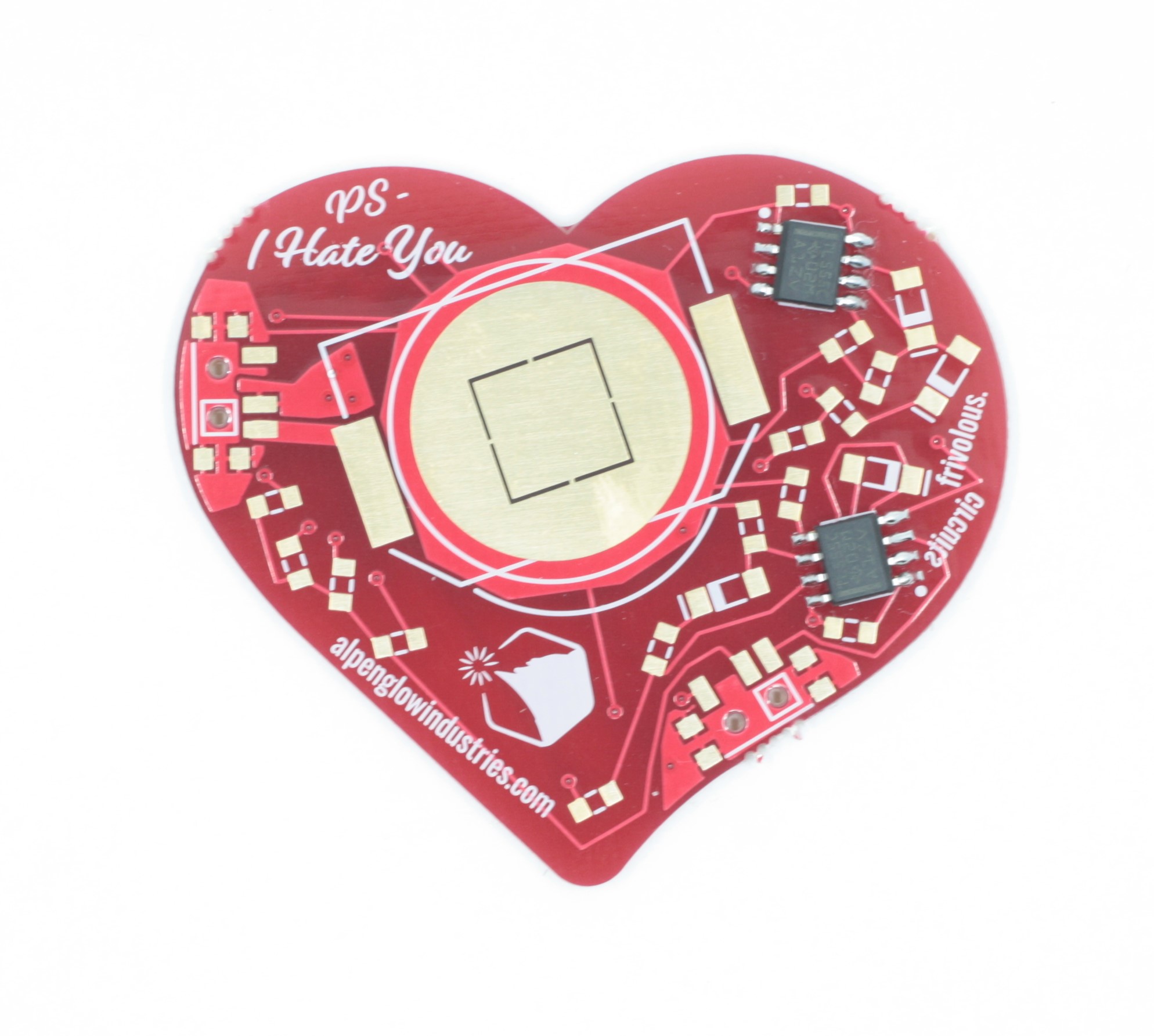

I came up with this project after reading this snarky tweet about how the RPi Pico was "literally unusable" because a trace was at an odd angle. Having been designing circuit boards for 20+ years, I thought the resulting thread was hilarious. There were also pictures of other really weird cringe-worthy layouts, and I thought "Heh, it would be fun to do a terrible layout on purpose, as if you just threw a handful of components on a board and they stuck wherever they landed." Then I thought "Hey, Valentine's Day is coming up, I could make it a snarky Valentine because that holiday is total BS anyway." And thus, PS - I Hate You was born!

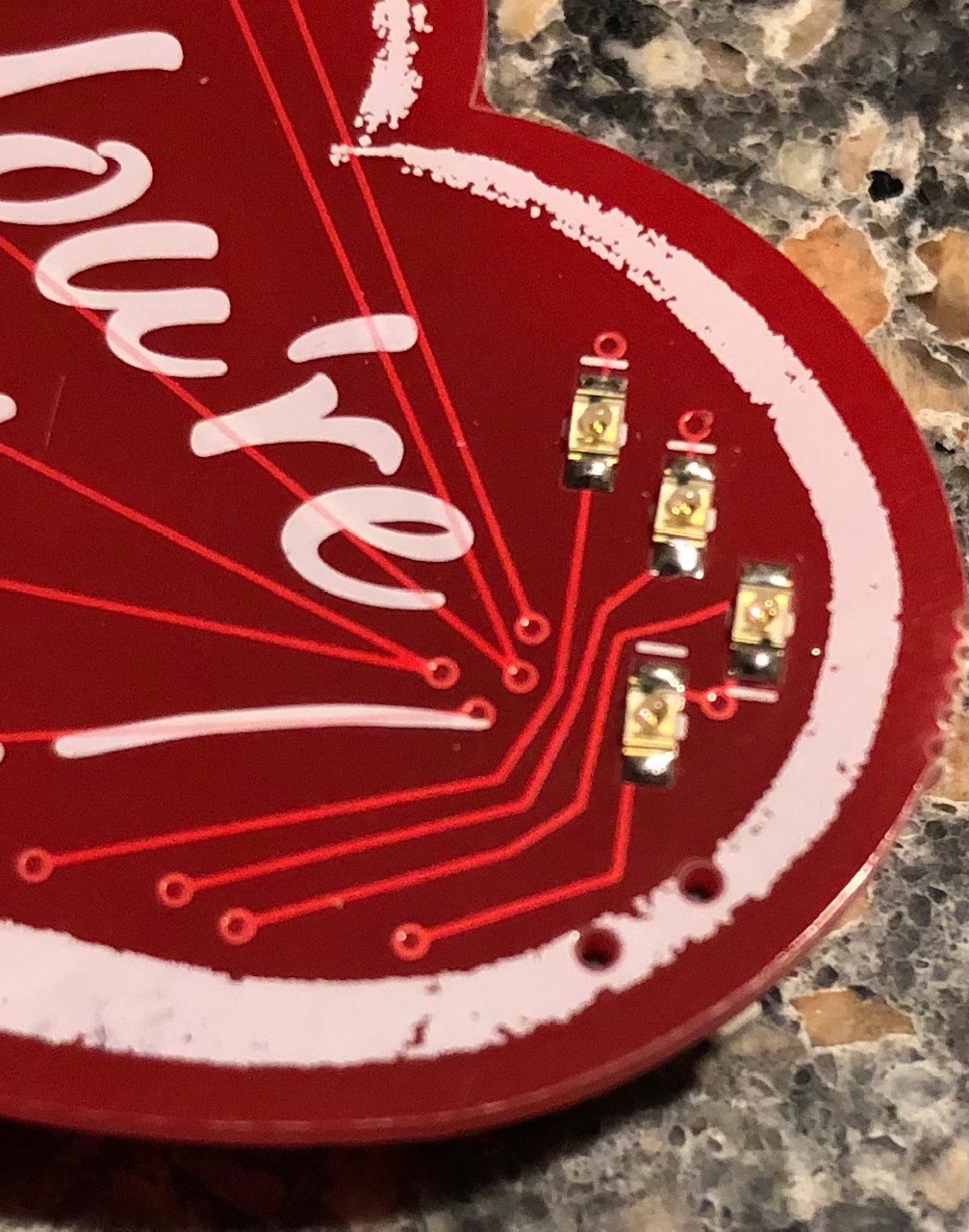

First, you'll note that there's not a perfect 45 or 90 degree angle anywhere on the thing. In fact, there are even some traces with ACUTE ANGLES. 😱😱😱

There's a single word backwards on the bottom silkscreen! 😘

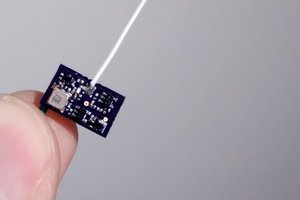

We used mini-MELF diode packages just because they're cylindrical and love to roll off the table and can be hard to grip with tweezers. 🥰

I mean, who does this with traces? 😍

We purposefully left reference designators off of the silkscreen. Guess you'll have to refer the assembly diagram files to match components to their places.

However, in spite of all that, we kind of think this board looks cool and we're stoked with how the graphics came out. And who doesn't love some 555 timer shenanigans? We're using one timer to make a low frequency, about 1 Hz, pulse train with a about a 25% duty cycle. We're using the other 555 timer to create a continuous roughly 10 Hz pulse train. The low frequency timer's output is hooked up to the high frequency timer's RESET pin, so the high frequency timer output is on only long enough to let 2 pulses out. The result is a twice-per-second heartbeat-style pulse that's used to blink the LEDs.

💓💓💓

Of course, we recognize that not everyone loves blinky things. So we have a "solid on" switch that bypasses the timers, and just runs the LEDs straight off the battery voltage. We also have an ON/OFF switch because we don't actually hate you _that_ much.

Happy Valentine's Day, all!

Alpenglow Industries

Alpenglow Industries

Hulk

Hulk

John Wetzel

John Wetzel

Steve Smith

Steve Smith

Nice, I don't know if it's irritating me more that you used the correct form "you're" instead of seizing the opportunity to put "your" or that you used two 555s instead of a 556, although if that was deliberate, I salute you.