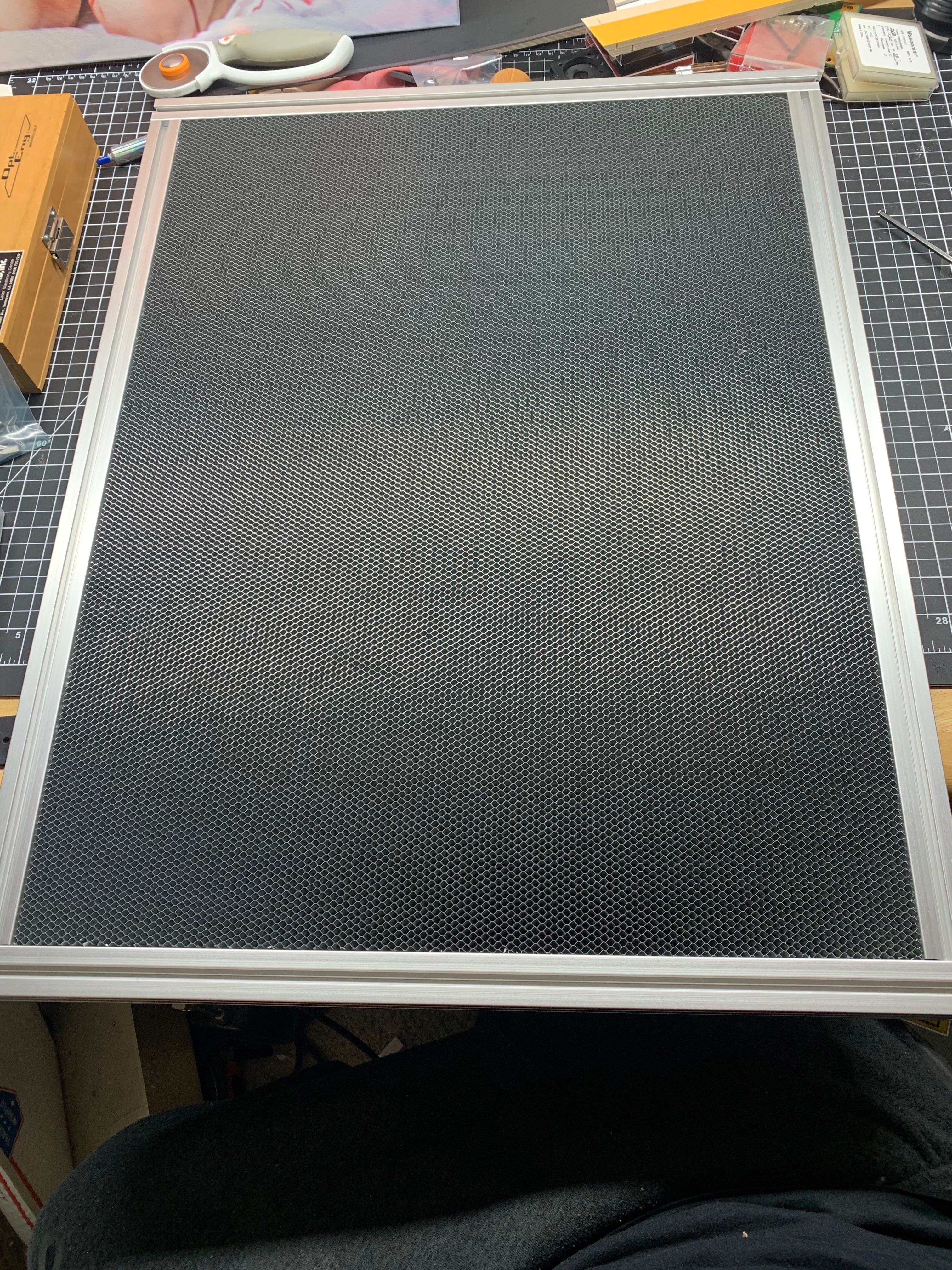

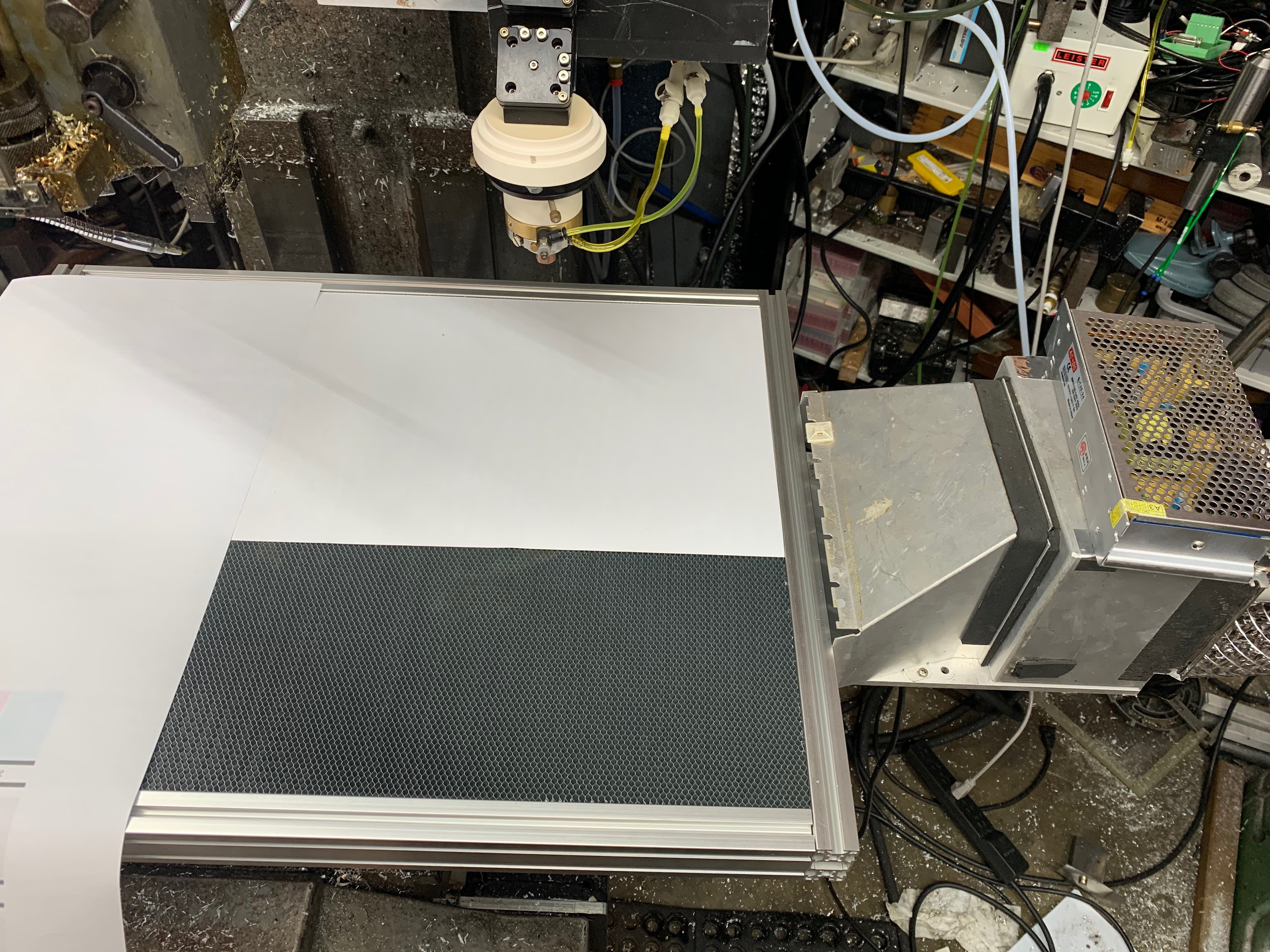

Finished up the cutting table, have not attached the fan to it yet, just need to make a couple holes to do that.

Now that's out of the way it's time to do some cut tests. For this I made up a little program that cuts and inch over and a quarter inch down and then steps up and goes an inch back and another quarter down at another speed increment. Keeps doing this for a few iterations so I cans where it cuts the cleanest. For this test I used some scrap .35mm latex sheeting, one of the main things I will be cutting with this.

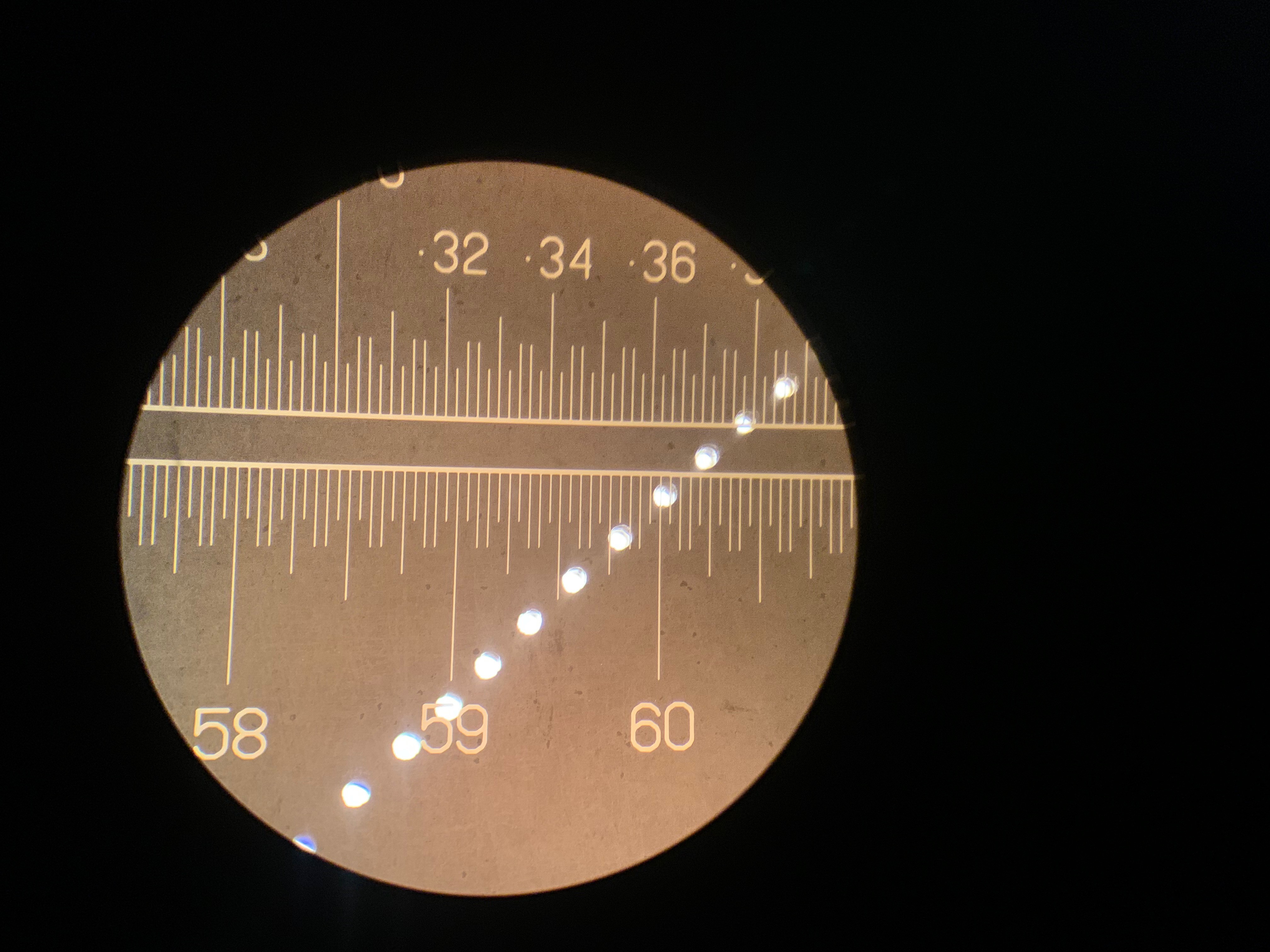

I found that 100ipm at 12.5% duty cycle, 20khz, in Enhanced Pulse Mode made a nice clean cut.

Works nice!

I figured that if a dropped the PWM frequency down a bit I could use it to mark the latex without going though it. All I succeeded in doing was drilling a whole bunch of 100um holes in the latex. Whoops.

What I might try next is to lower the rep rate and feed rate down and use the higher power pulses to cut instead of a QCW beam, it might cut cleaner that way.

The thing is getting pretty close to what I consider done, still need to make an enclosure over the laser itself to keep crap out. I probably will just have something cut and bent though OSHCut.

Jerry Biehler

Jerry Biehler

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.