When looking at e-bay for Tyco US-1 parts, it's quickly apparent that there are a number of plastic parts that commonly break over time. One of the first I ran into was for the box unloader. You can find the main track piece for this very frequently, but there's a special sign that only swings one way that is almost always broken or missing.

One of my big hobbies is 3D printing (and designing 3D parts). As for Tyco US-1, my interest is less in having everything be perfect & stock, and instead in having something that I can feel comfortable having my kids pull out and play with. I expect that some things will get broken, and that needs to be okay. I also love that, with 3D design, I can design something once, and then not only can I re-print it as many times as I want, but others can as well. All it takes is one person to design a bunch of simple replacement parts, and then all of these broken, unusable parts are suddenly more valuable and easily restored.

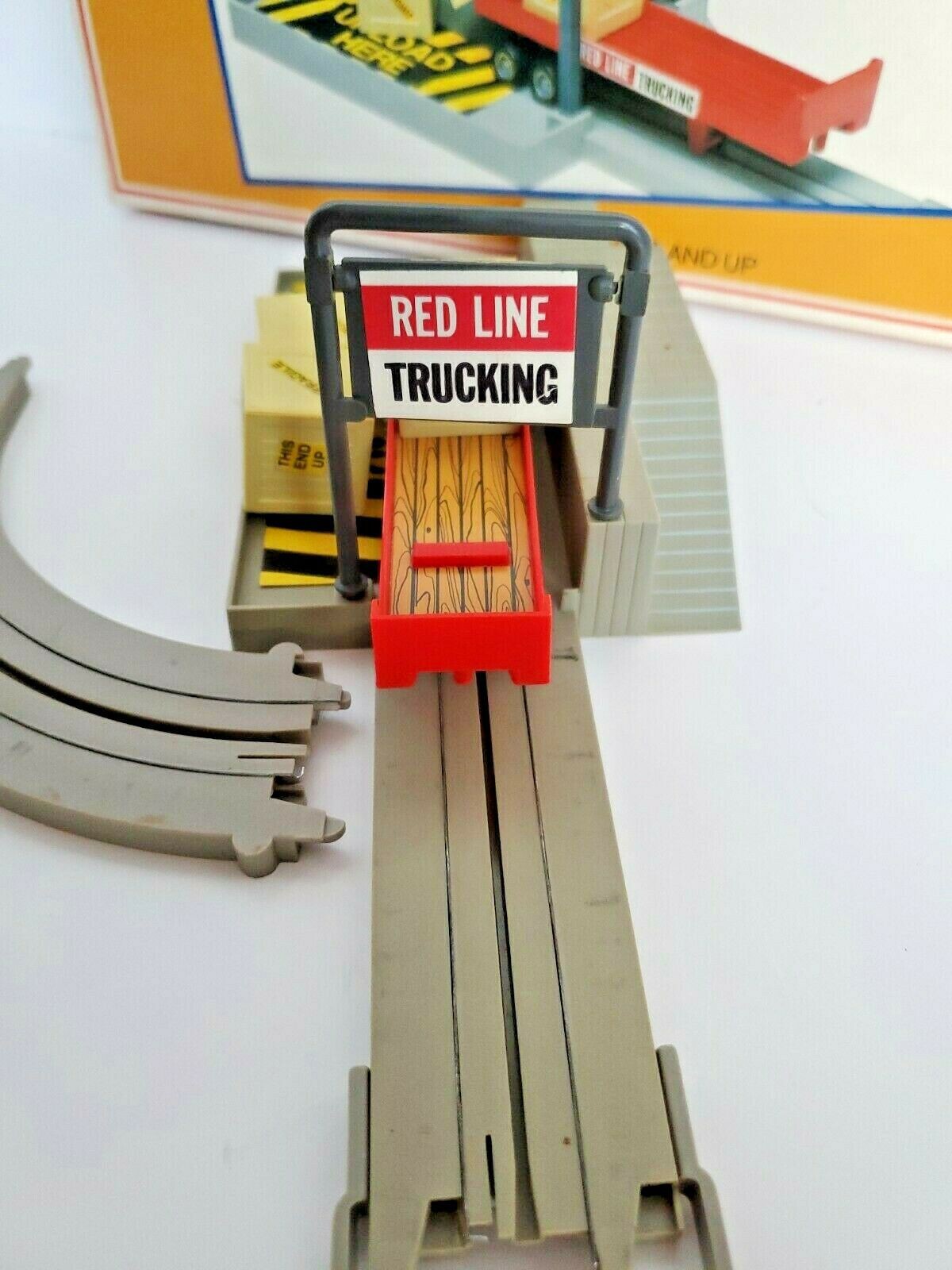

So yeah, you probably guessed that I designed a replacement sign & sign post:

Functionally, it works great. And while the picture gives you a close-up view where you can see all of the printing imperfections, in practice, they're not so visible, and it works great.

https://www.prusaprinters.org/prints/55299

From this point, I've jumped off and started designing a number of other parts that seem to break often:

The dump yards are super common, but the original walls are frequently warped, have their pegs broken off, or are just flat missing.

https://www.prusaprinters.org/prints/55300

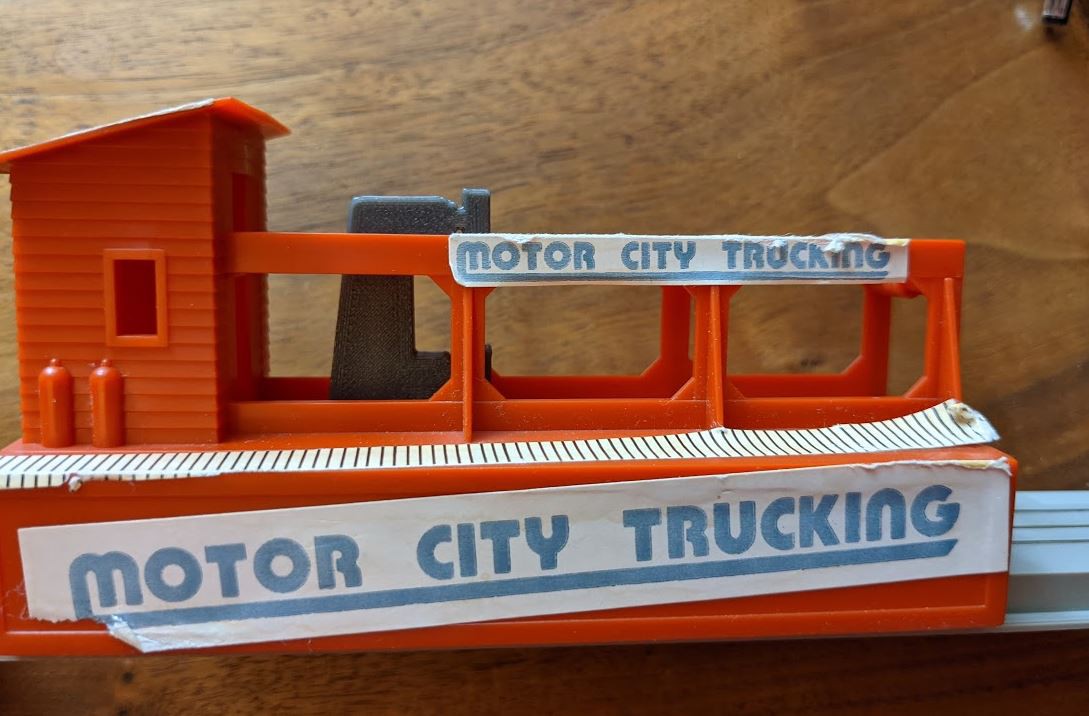

I picked up a "Motor City Trucking" car carrier loader (I never had one of these as a kid, but it looks cool!) The "backstop bracket" was broken, but easily replaced with a 3D printed part (grey bracket in the middle).

https://www.prusaprinters.org/prints/57106

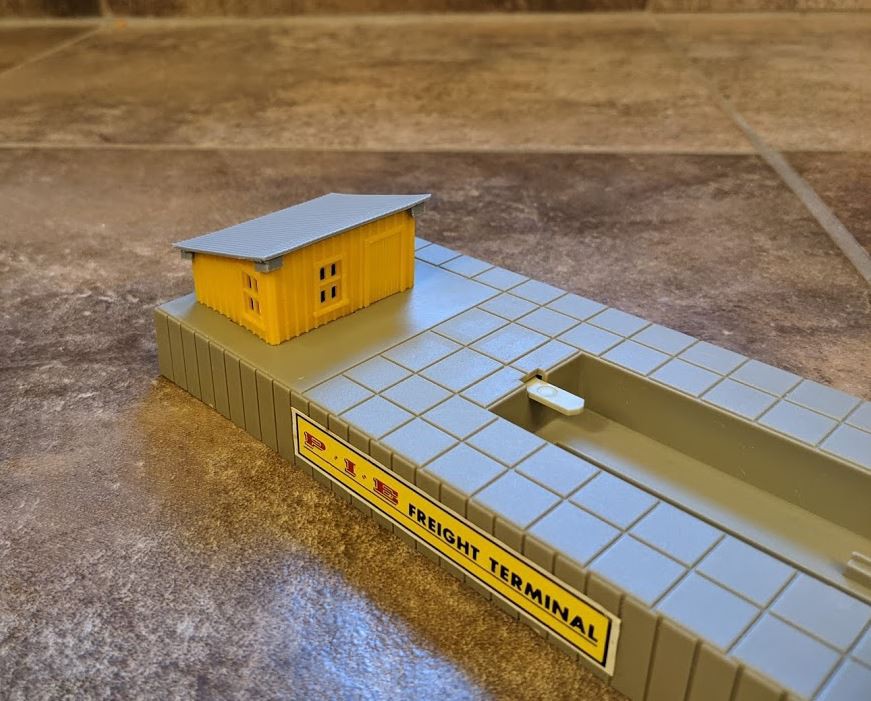

The shed was missing on this Freight Terminal. This was kind of a fun build, as I designed the building to be printed flat, and folded, just like the original building was assembled. It's a surprisingly simple design that allows all of the walls to be printed as a top surface of the 3D print (so they look nice), without the need for gluing anything together. It's interesting how using a similar design that worked so simply with injection molding applies so well to 3D printing.

Mike Turvey

Mike Turvey

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.