For a first project I wanted to cut out some wing profiles for a DLG. For this initial project, I only wanted 20" span, so a big easier to handle.

I cut out some wooden guides to pin to each end.

These are the wing profiles from the model plans I'm basing it from. See (tbd) project for more details.

I tried simply drilling some holes and pinning them to the ends with trial cuts. I found the lead in and lead out were awkward and didn't allow smooth motion, so wasn't a clean cut. I glued on a steel pole to act as a lead in, and it worked much better.

Here is that, pinned to an edge, post cutting. (I cut two out of the block, so the other is also visible.)

Note that I've left the cut pieces in provide support in future cuts.

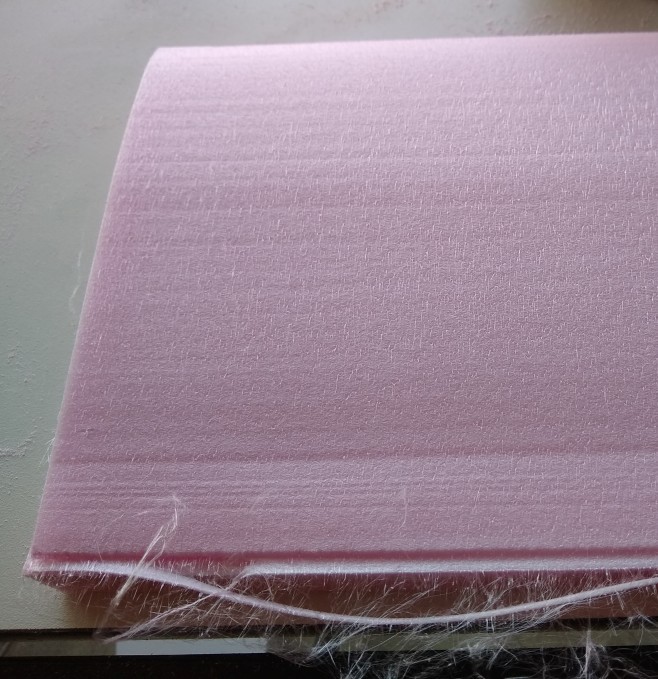

Cutting creates a lot of very thin hairs, though they are easily sanded off. You can see the all over the surface as well as out the end of the cut.

I did several practice cuts before working to make the final pieces.

Tricks I learned:

- The higher tension (20-30lb) was very helpful

- Marking off 1" sections on the top at both ends is very helpful for making sure you are cutting evenly

- It was best to set the cutting wire on the far side guides, then hold it only from the back middle(on the elastic) This allowed the weight of the bow itself to trace the pattern pieces

- I needed more pins than I'd expected to prevent the pattern from shifting. I used 5 through each piece, as well as 2 more under the thinner side at the end

- For this wire, it worked best around 4.3A. Higher and it was very dependent on cutting speed. Lower and it cut super slowly

Overall it works fantastic, though takes a little practice. The last set I did turned out fantastic, with very little sanding needed. This will probably be my go-to method of making wing profiles in the future.

Quinn

Quinn

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.