Part of the excitement getting the 1mm version of the card ready in time was the last minute issues. A few days before, it wasn't looking good.

I came up with a nifty way to snap the piezo co-planer into the flex circuit to achieve a 1mm thick beeper. The weekend before Crowd Supply Teardown, I started to assemble everything. It was all going fairly well at first. I had purchased OSH Stencil with the OSH Park flex and I have the Miniware MHP30 so the tiny leadless packages were not too intimidating. The fun part came when I tried to solder in the piezo.

It seemed to stick to the center pad, but for the life of me I could not get it to solder to the outer ring. I tried and tried and no matter how much I cooked it nothing would stick to the disk. I took the disk away from the flex, scuffed it, globbed on flux and cranked up the iron but nothing would stick. In a moment of desperation, I decided to look up the part number to check the datasheet. Then I discovered that I had ordered a piezo buzzer built on a stainless steel disk. They claim it is possible to solder with special solder and flux, but I wouldn't know as that is not what I had on hand.

I was trying to find a way to remedy this in time for the event. I was afraid that I may still struggle with a brass disc, and didn't know how fast I could get one. I thought that maybe I can find a solderless way to make contact. I looked for some conductive glue on Amazon and found a few including this silver conductive paste available Amazon prime: https://a.co/d/0i3swAch

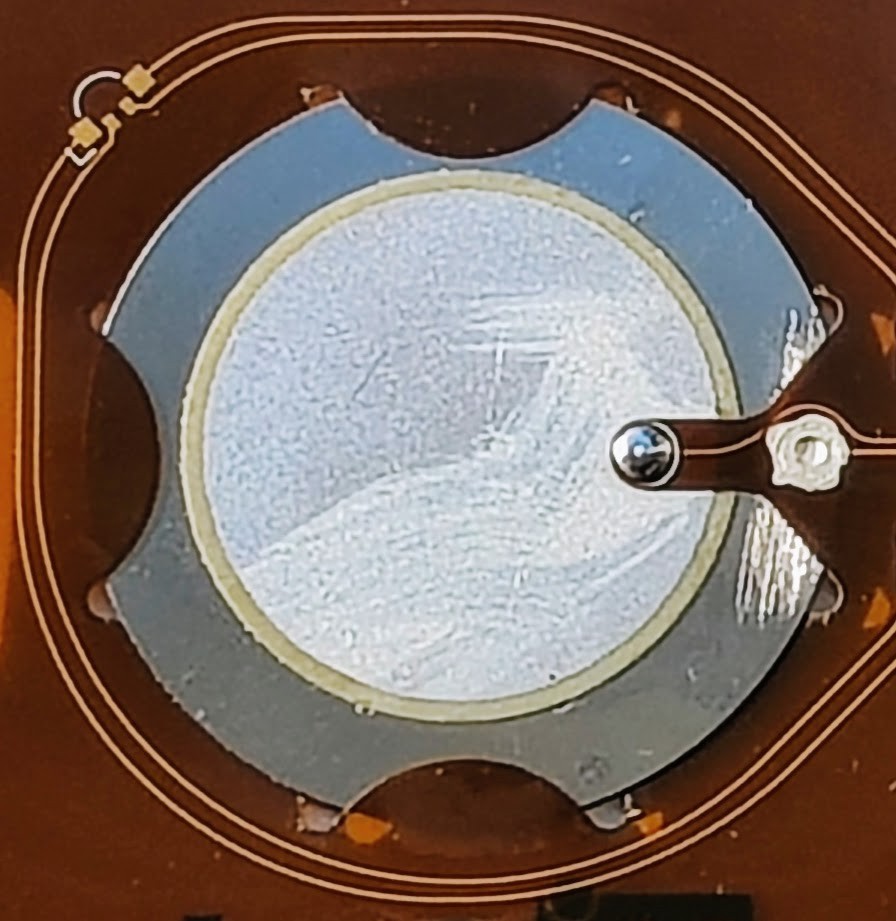

When it arrived I assembled the second bare flex circuit (the first was cooked beyond utility). Before sliding the piezo in, I sanded the disk to make sure there was something for the paste to grab, and then slid it into the flex. The center contact was not difficult to solder so I soldered it to hold the tab in place while gluing. I then applied some of the paste to the second contact and made sure it went through the hole to reach the disk. It said you could cure it faster with heat, so used my heat gun on it for just a little and walked away a couple hours to let it finish setting.

A couple hours later I came back and tapped the antenna with my phone, and heard some of the most delightful tones emerging from the 1mm thick beeping, blinking business-card badge. What a relief.

greg

greg

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.