These ware the candidates for sensing liquid level in the Plant pod device:

1. Solid state capacitive sensor

2. Custom encoder strip based (Optical)

3. Custom magnetic encoder based

And the winner is! Custom magnetic encoder based one, and here is why.

- Solid state capacitive sensors are usually designed to sense water level, which isn't the case here. Liquid solution used in this case can have different conductivity levels depending on the chosen solution. They are also sensitive to human presence, non linear and have a level resolution of about 1mm, which in our case is translated to about 11ml of liquid. Here is an example of solid state sensor

- Custom encoder strip solution uses optical type of the encoder and the bar strip, similar as you can find in the desktop printers. Resolution can be in the range of 0.125mm which translates to a resolution of about 1.375ml. Reading is linear and precise, but considering environment of the operation (Liquid and moisture) we decided that this is not a good choice.

- Custom magnetic encoder solution. If take an example of 12bit axial magnetic encoder, we get an approximate resolution of 0.08789° per bit, and if we substitute the values in the arc length formula

l = 2πr (θ/360)

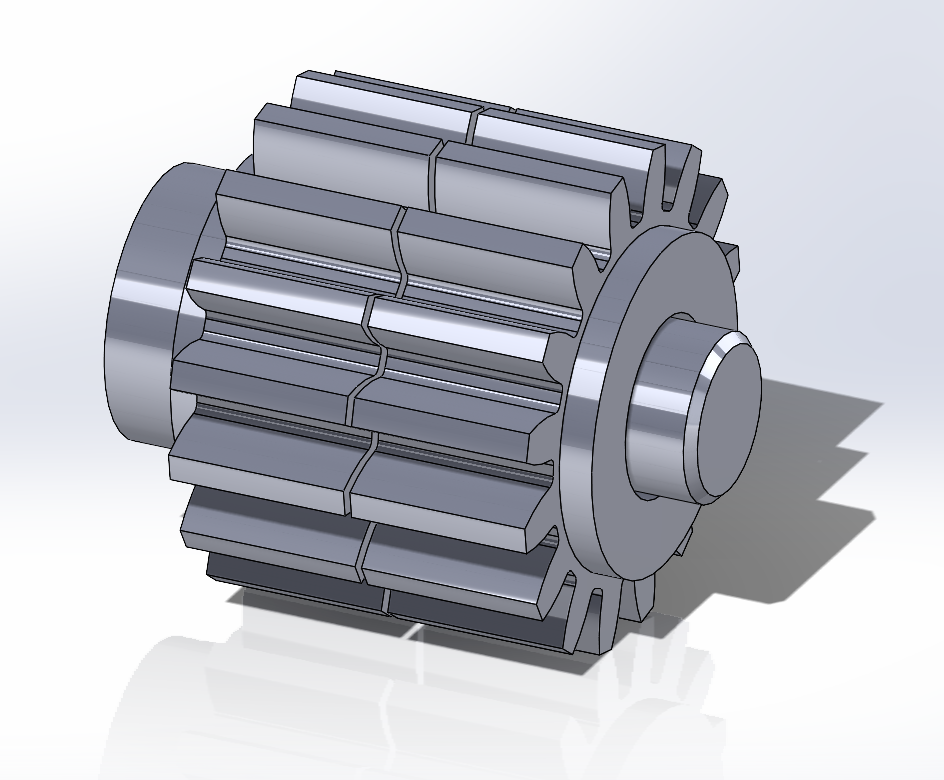

for the given gear diameter, we get a result of 0.005mm of horizontal travel resolution which translates to a 0.055ml resolution, not bad, that is pretty precise. And what about accuracy? Well if you take a look on the next picture

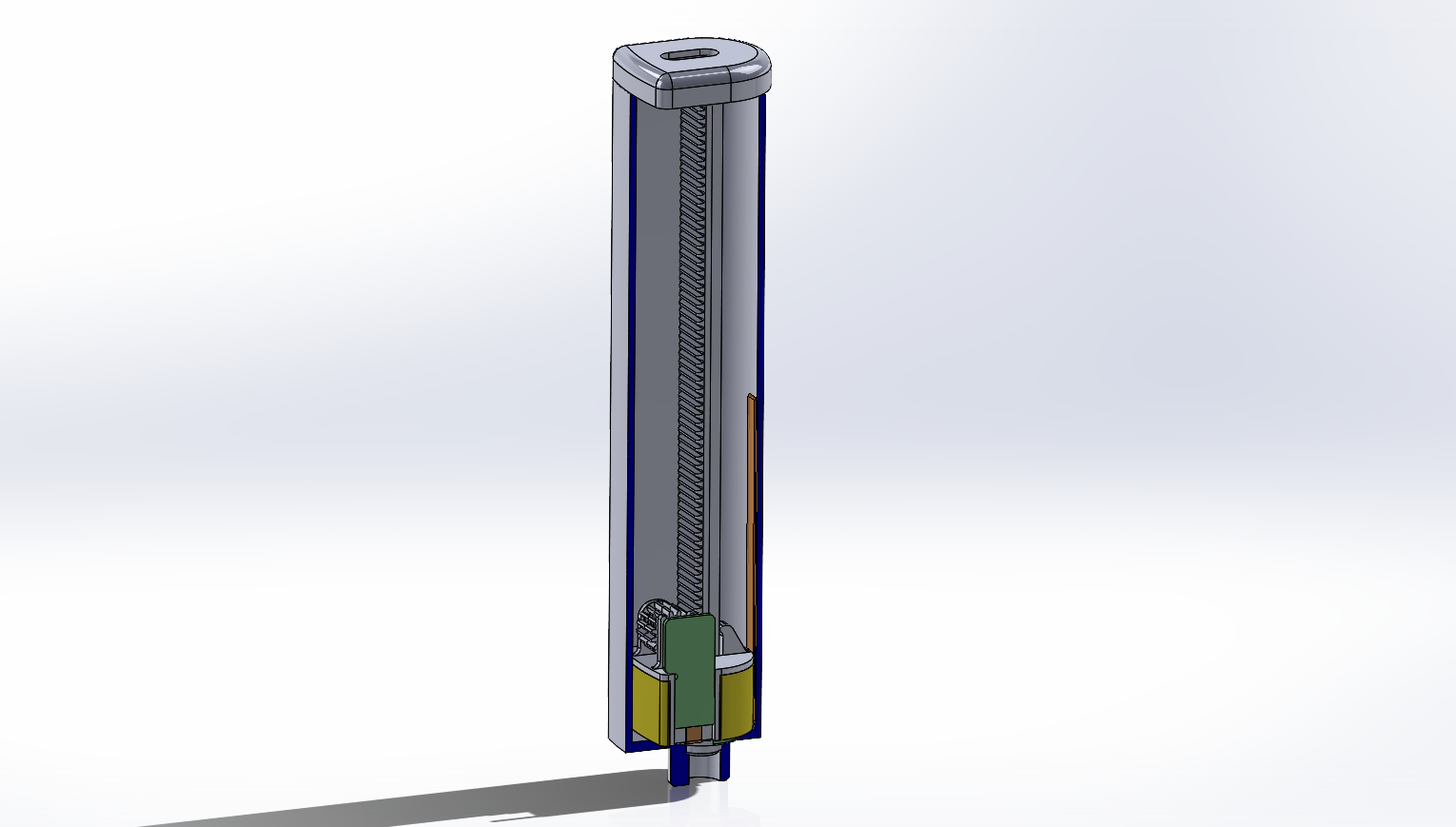

you can see there is a split in the gear. Gear is actually designed to minimize backlash (Spring load between two parts of the gear) and provide best possible accuracy and precision. There is one more thing to solve, and that is an liquid level offset, before EVA foam float starts to move, it needs some minimum liquid level, but this value is tied to the buoyancy, which can be considered constant, and sensor has down position detection, so this value can be automatically compensated by the software.

Except from measuring exact liquid level in the Plant pod device, this sensor will be used to auto calibrate pump/valve system, that will then also be capable to estimate operation time/number of cycles for the injection of the required amount of the liquid.

Nikola Secerovski

Nikola Secerovski

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.