Aha, so the elbow pancake stepper was the cause of my print quality issues. Apparently it doesn't hold microstep positions as well as the larger ones, causing major ringing artifacts as the arm is able to vibrate between the two full step positions. I tried increasing the current, but it didn't seem to have any effect.

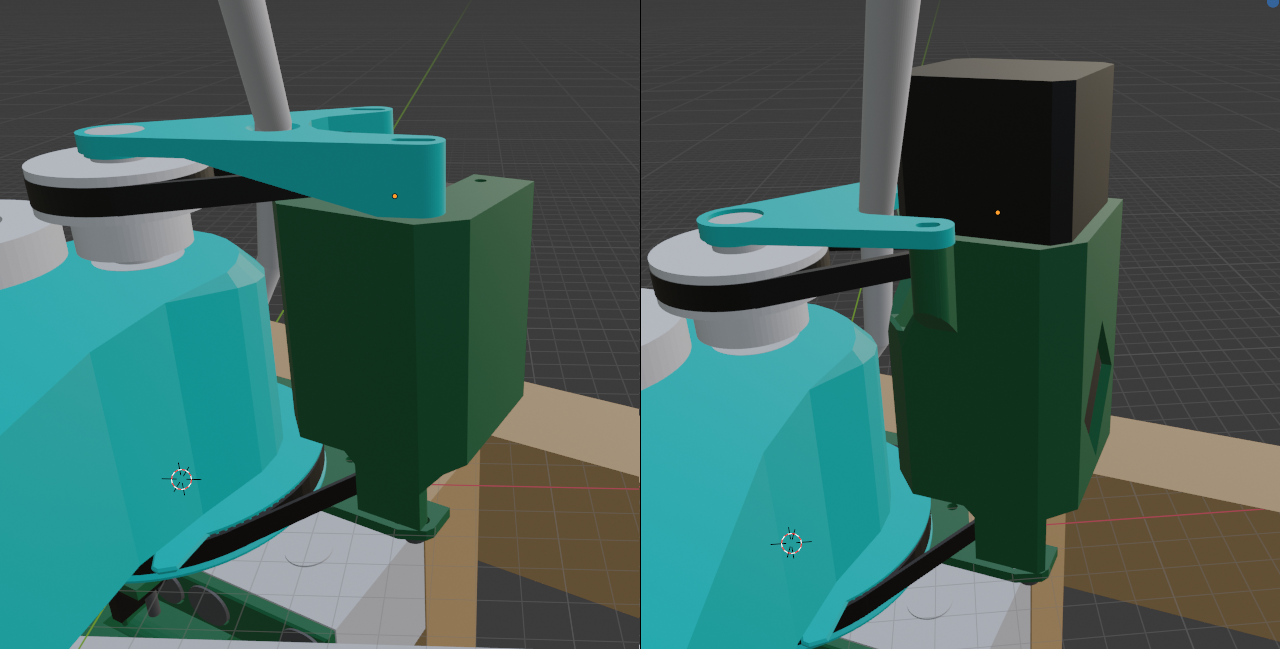

I redesigned the motor tower to hold a second 34mm up on top, which is not quite as elegant as the old design, but actually a bit nicer functionally because it provides a place to trap the bowden tube/wires without having to pass through a hole in the top bracket (which is a major pain if you ever need to pull them back out). I also added a window to improve cooling (diamond shaped to allow printing without supports).

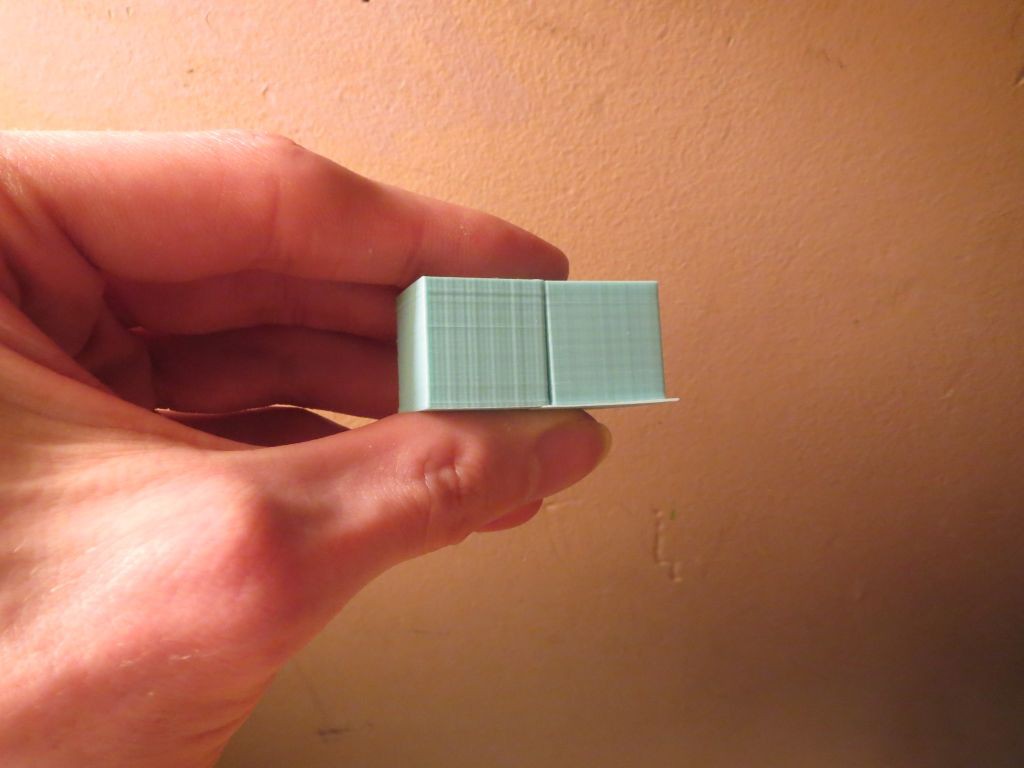

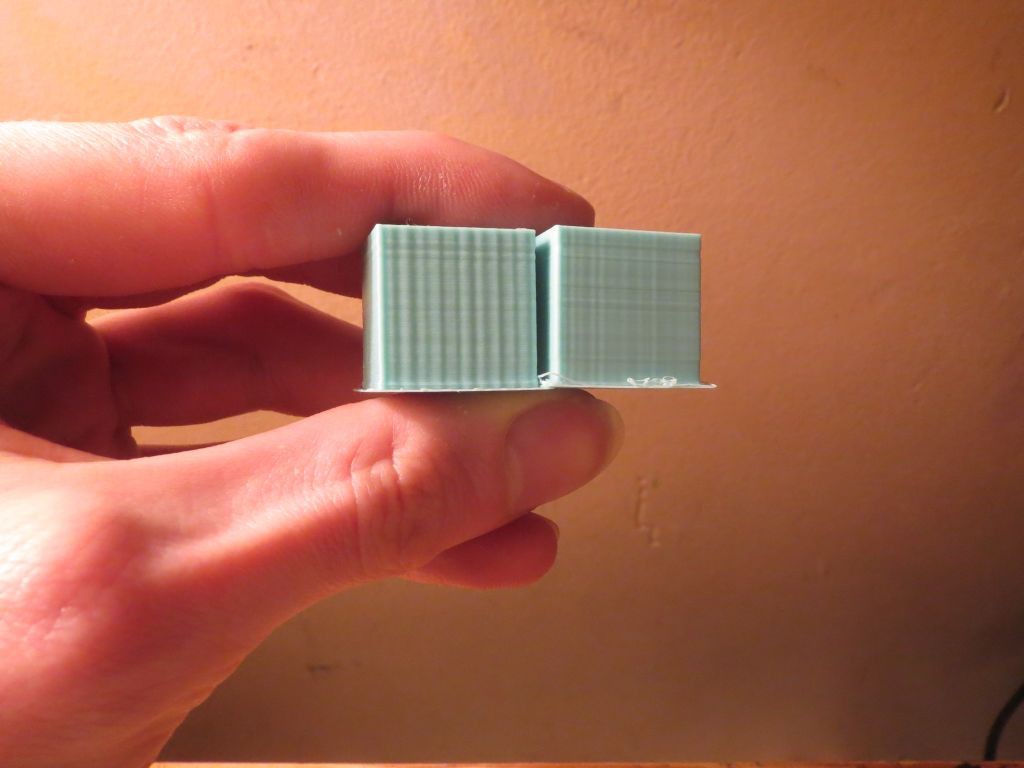

The photos show before and after of 20mm/s and 60mm/s print speeds. Ripples are much smaller now, especially at high speed.

dekutree64

dekutree64

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.