I've developed the designs for 2 different bases to attach the handrests and clusters to. One is based around a steel sheet, with the clusters attached magnetically, for maximum adjustability, and the other is a static design, with the clusters set at a specific location and orientation, for maximum stability.

Adjustable Design

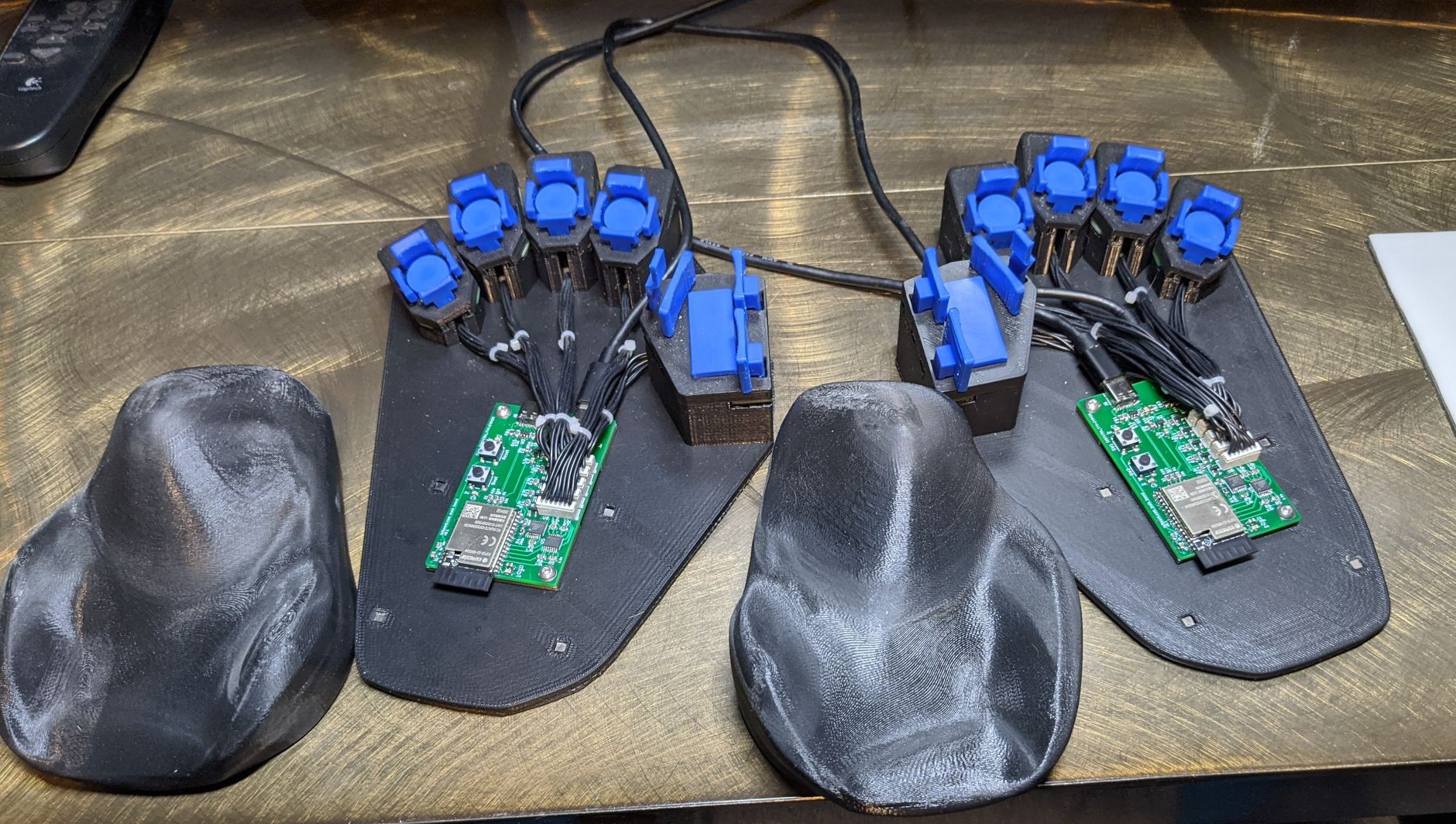

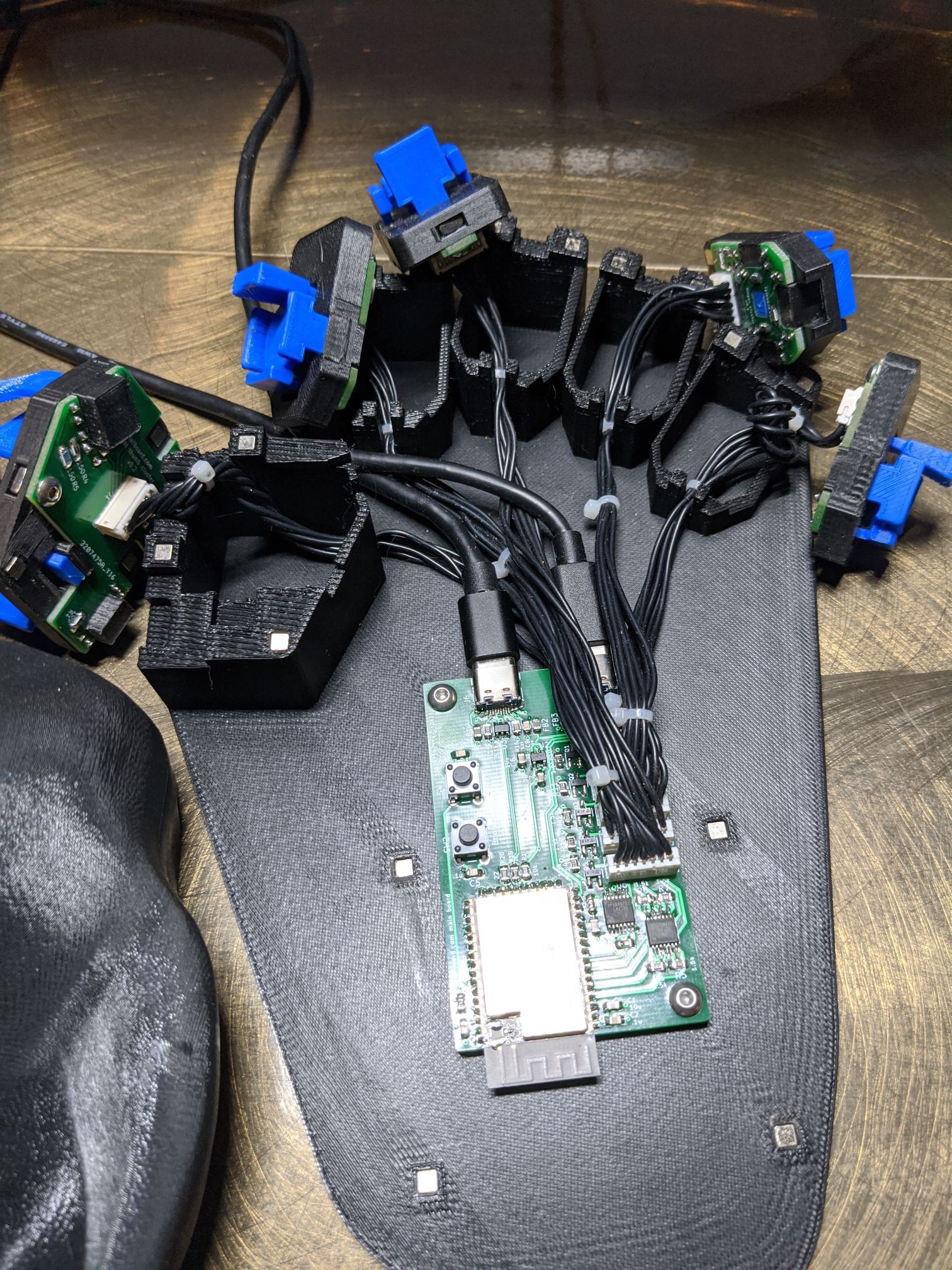

Static Design

The idea is that you start out with the one that uses a steel sheet, and live with it for a while, adjusting the positions of the clusters until you're satisfied with how it feels. And then you take some measurements (exact method TBD) and use the position and orientation of all the clusters to make a static base.

When I was originally setting up my v1 lalboard, it took a while before I got everything positioned just right, with lots of small gradual tweaks as I tried to figure out the best positioning. It's surprising how much difference even moving a cluster less than 1mm can make in how everything feels under your hand.

The steel sheet is great for adjustability, providing six degrees of freedom/adjustability for each cluster. But it's not a great permanent solution, due to how difficult is it to get everything set up *just right*. So if you accidentally bump it and move things around, it's rather annoying trying to get everything back exactly where it was.

The static base solves this by providing a stable, immobile mount for the clusters. It's also smaller (no margin around the edges past the clusters), and provides somewhat better cable management (although I still have some ideas to improve this).

Ben Gruver

Ben Gruver

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.