I have designed a new version, I'll print it out and test it tomorrow when some bearings arrive. I am also using a new motor and it does seem like it has enough torque.

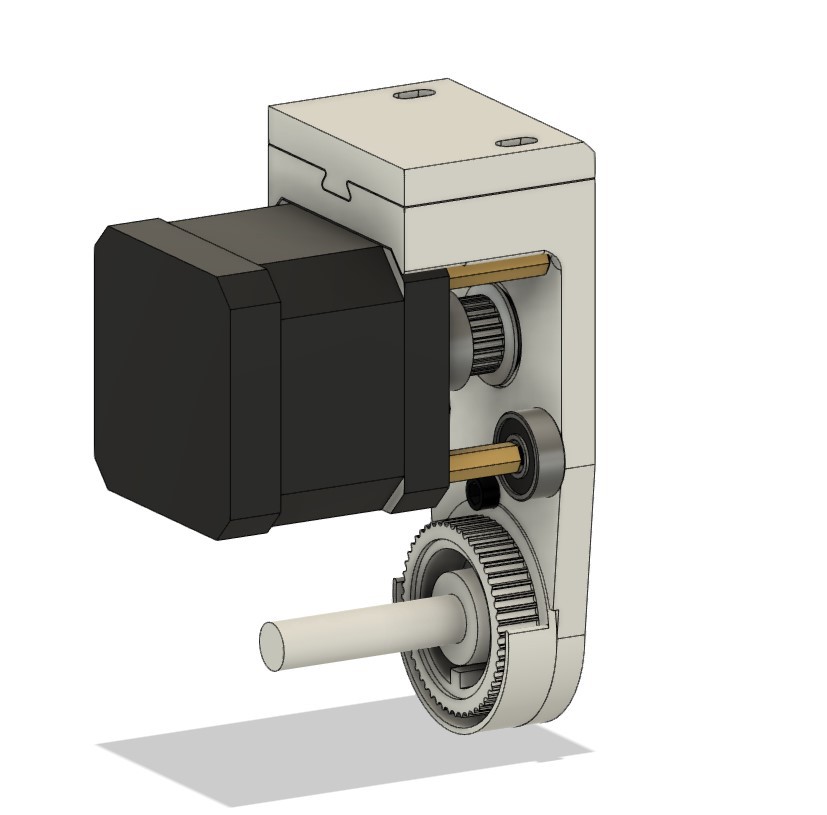

I have taken a different approach this time. A simpler part with increased stiffness around the motor mount and support for the shaft that will be facing constant downward force due to the tension of the belt.

Tensioning the belt on the previous version was done by moving the motor itself but now I have introduced a bearing although as I have not tested it, I may need to print an idler as the bearing could be too big.

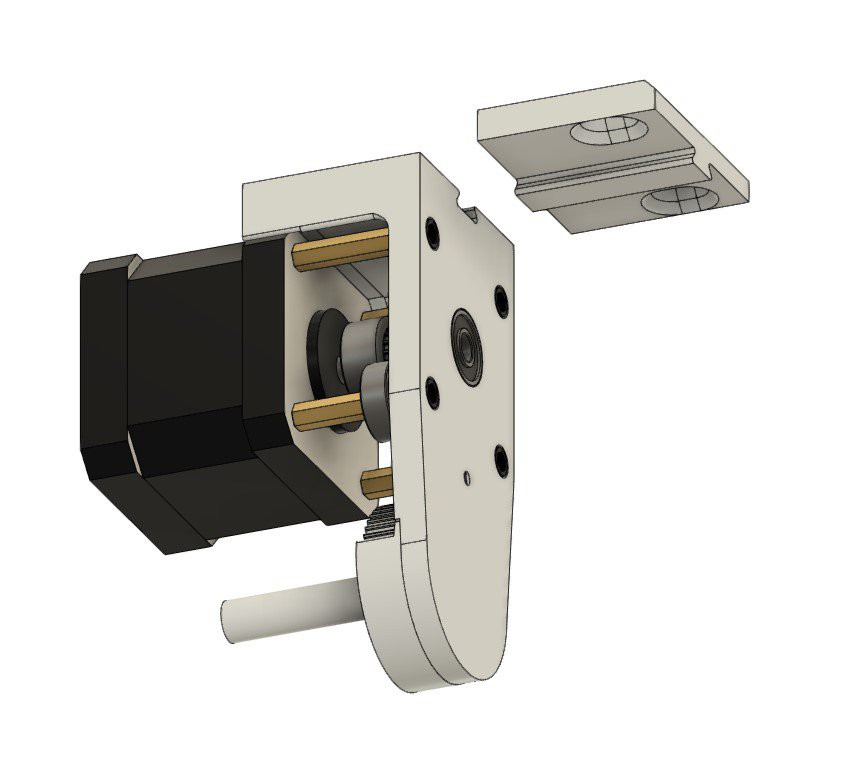

Another change is the way that the assembly will be mounted to the wall. It still uses the same mounting holes but since the motor pulley and the standoff pillars are in the way I would not be able to screw the assembly into the window frame. With V2 the top part (the male part of the dovetail) can be installed first and then the rest of the assembly can be slid on and hung from the dovetail. After this version is tested and I am happy with the performance I will carry on developing the software and then finally design a PCB to handle the POE stuff.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.