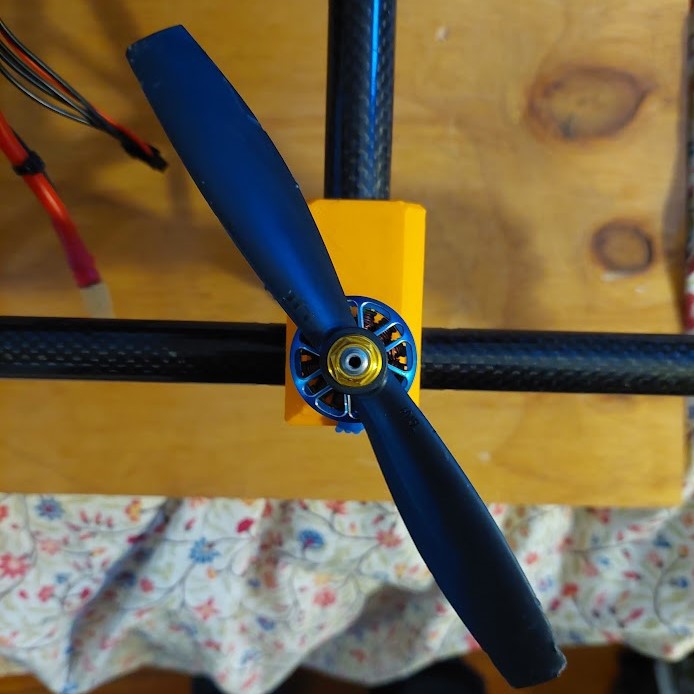

So if there's one thing I love, its overbuilding things. Like I've said, this drone is rock solid, but that comes at a cost of efficiency. You can look at some of my original photos from this project to see how bulky some items were. The "T" Braces are particularly bad, and have been for most of this project. They started out as these behemoth literal T braces, that took 4 screws each (Each!) to secure in place to the carbon fiber.

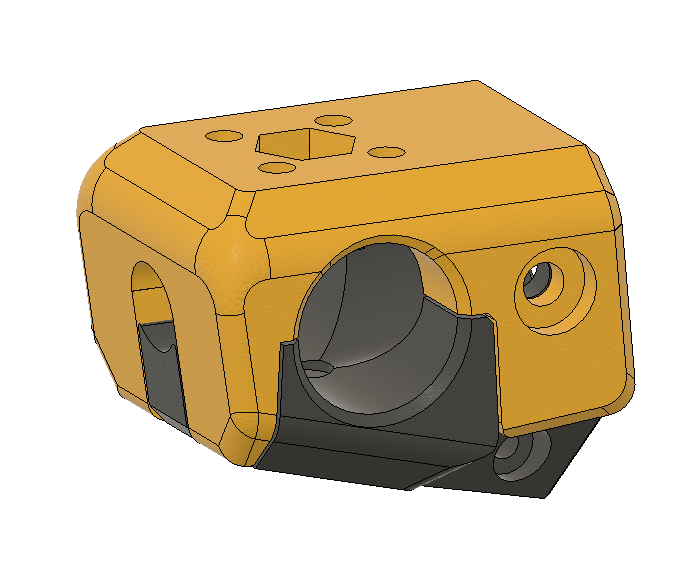

Then, after much consideration, I replaced them with this far improved design. Not only were they significantly lighter, and required less screws, the airflow around the part was much less obstructed.

We can do better though. If you look from above, there's still a largeish obstructed area

From the original part a year ago, we've got half the screws to secure the part, and less than half the size. I haven't attached it yet, but the 3D printing utility suggests a weight savings of 8ish grams each. Totaling a cool 32g, not including the reduce weight from requiring fewer screws to attach. In addition to the weight savings, I suspect there will be significantly improved flow around the part.

While I'm at it, I've slimmed down the landing gear, and removed the legacy camera mount, further reducing the weight of the drone by 106g. By the time I replace the T brackets, I'll have reduced the all up weight by almost 10% Just writing that out feels great!

The drone will be out of commission for a couple of days sadly, but I'm sure it will all be worth it!! Until next time!

Dylan Radcliffe

Dylan Radcliffe

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.