To control the printer there are 3 signals needed:

- Droduct Detect

- Encoder

- RS232

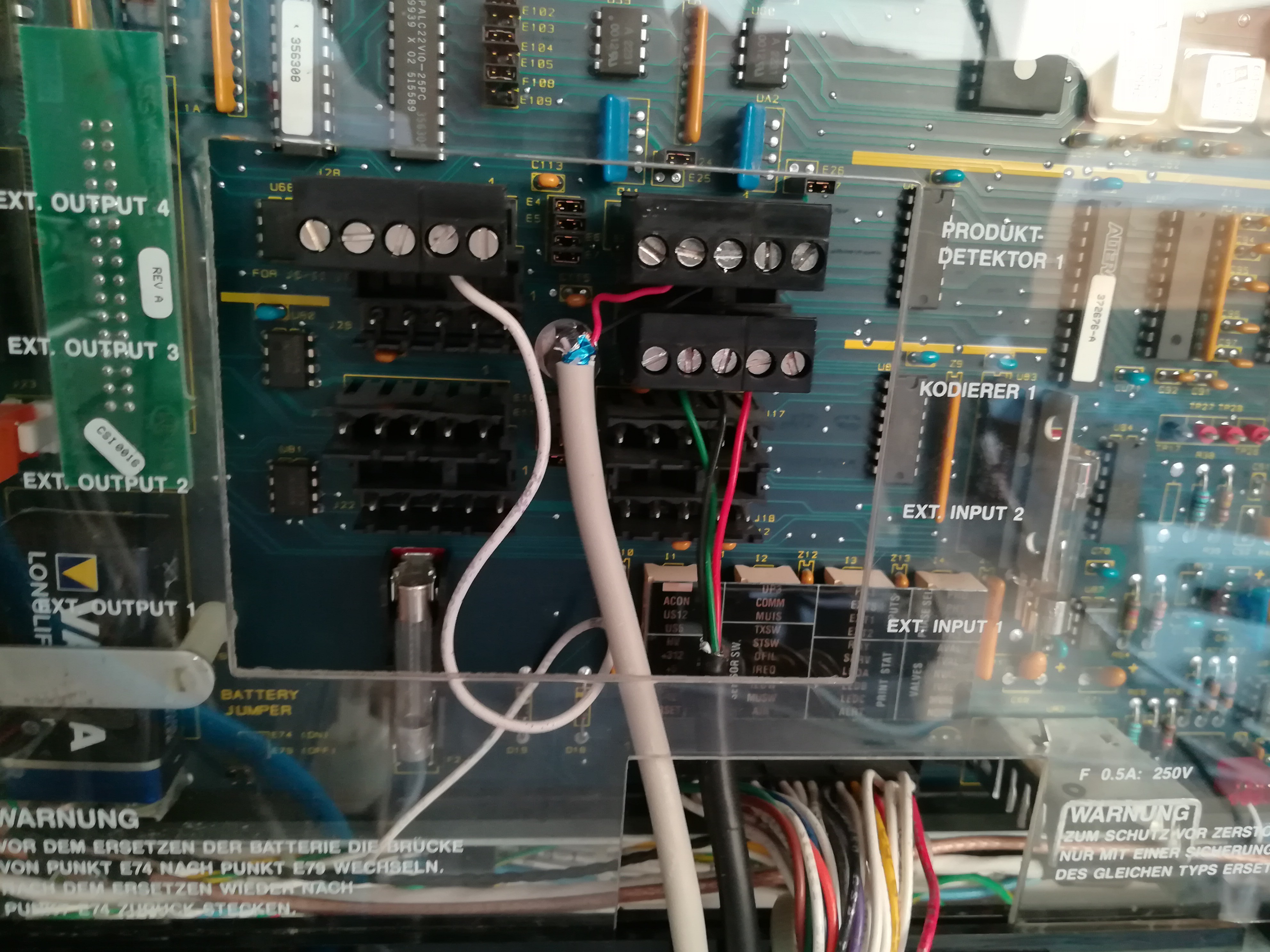

Product Detect:

Everytime the Product Detect signal is triggered the printer starts printing a message.

Encoder:

If an encoder is connected to the printer the printer is able to detect the exact position of the printhead, so that no matter how fast the printhead moves the message gets printed as it should be.

RS232:

To send messages for printing to the printer RS232 is used and the messages are send in HEX numbers.

The upper connection at the right is the product detect and the lower is the encoder.

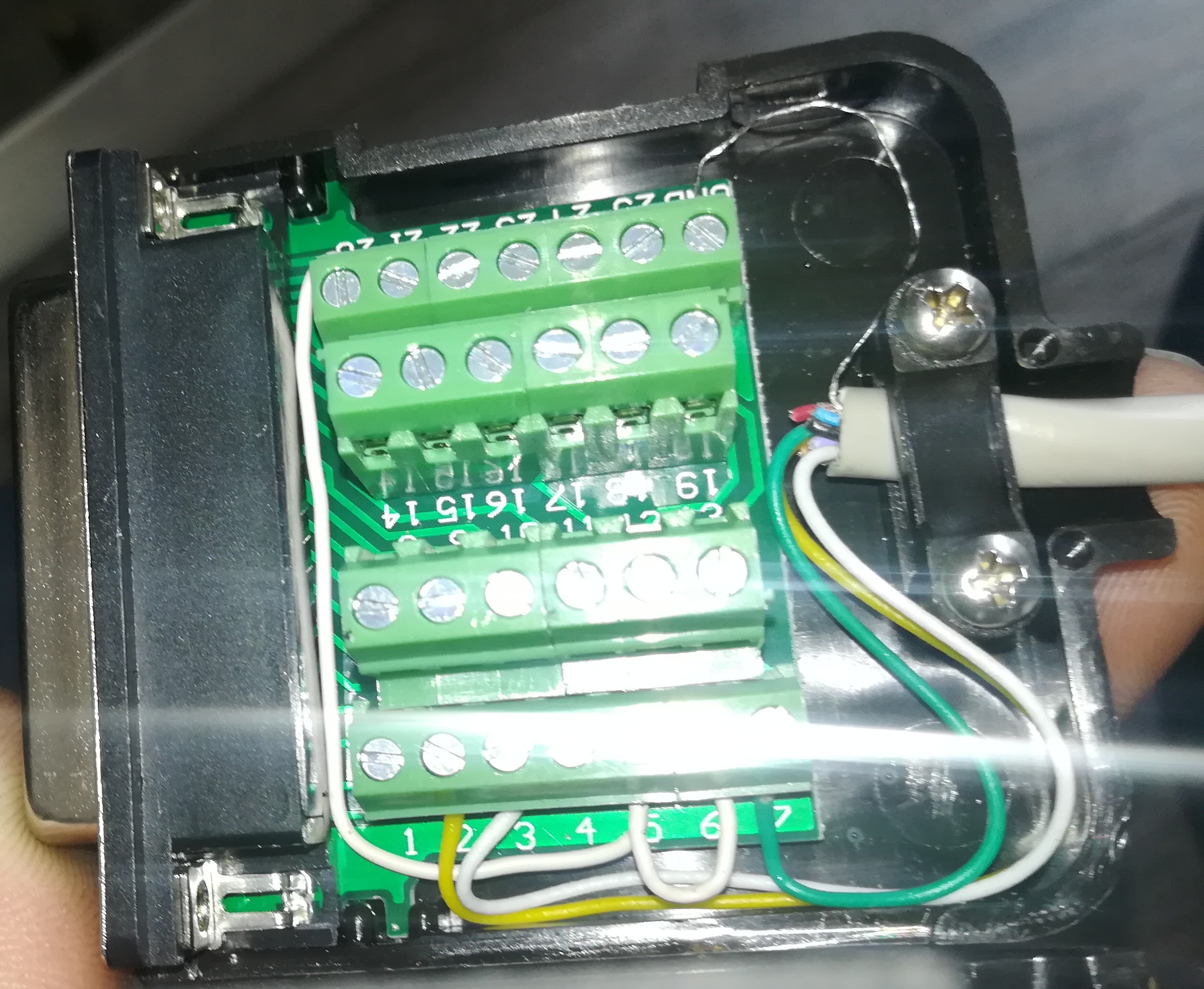

Here you can see the DB25 RS232 connector which is also able to use hardware serial.

Because I used software serial only 3 lines and some bridges are needed.

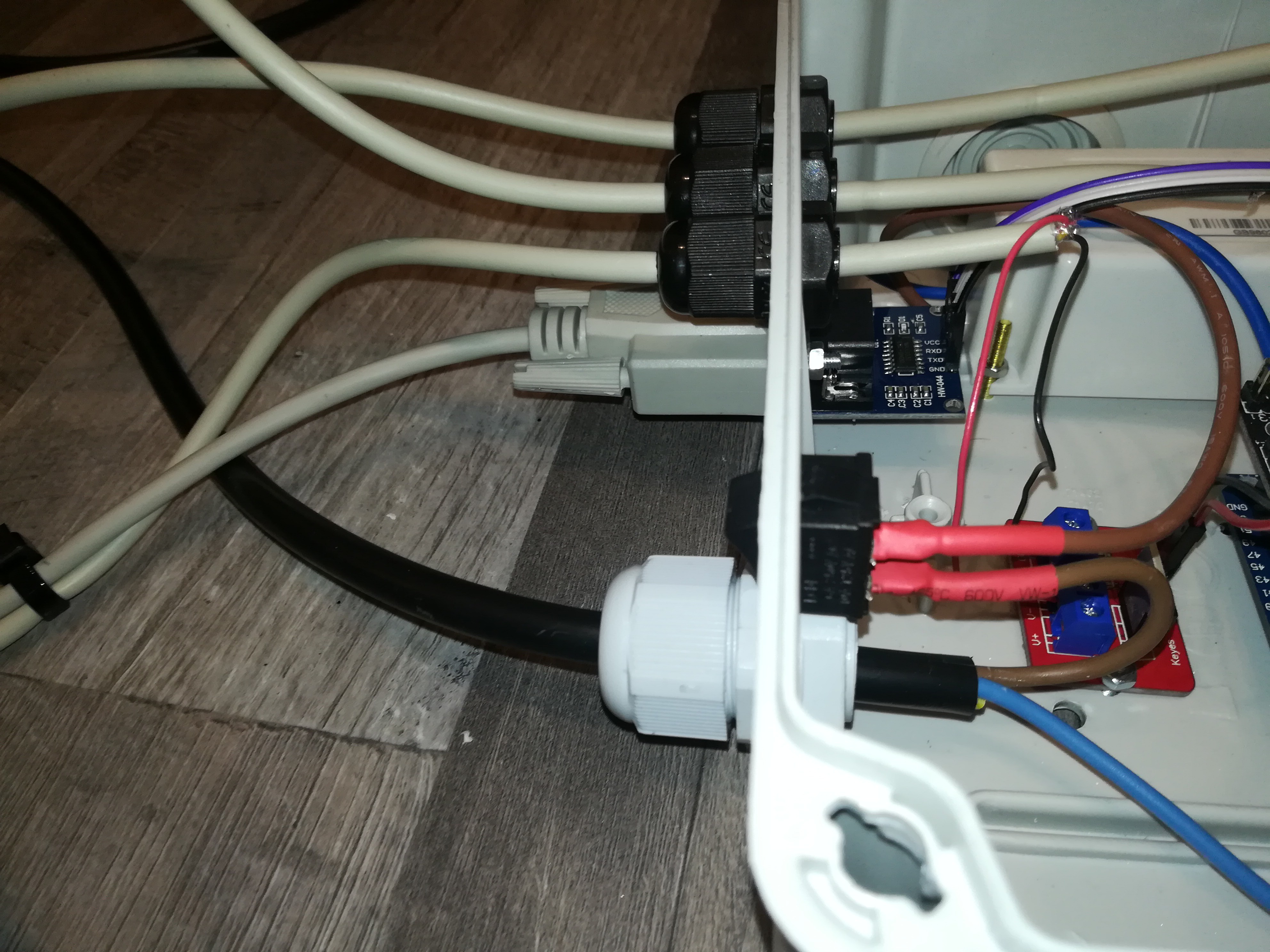

The other end of the cable is connected to a DB9 connector.

Which is connected to a MAX3232 board.

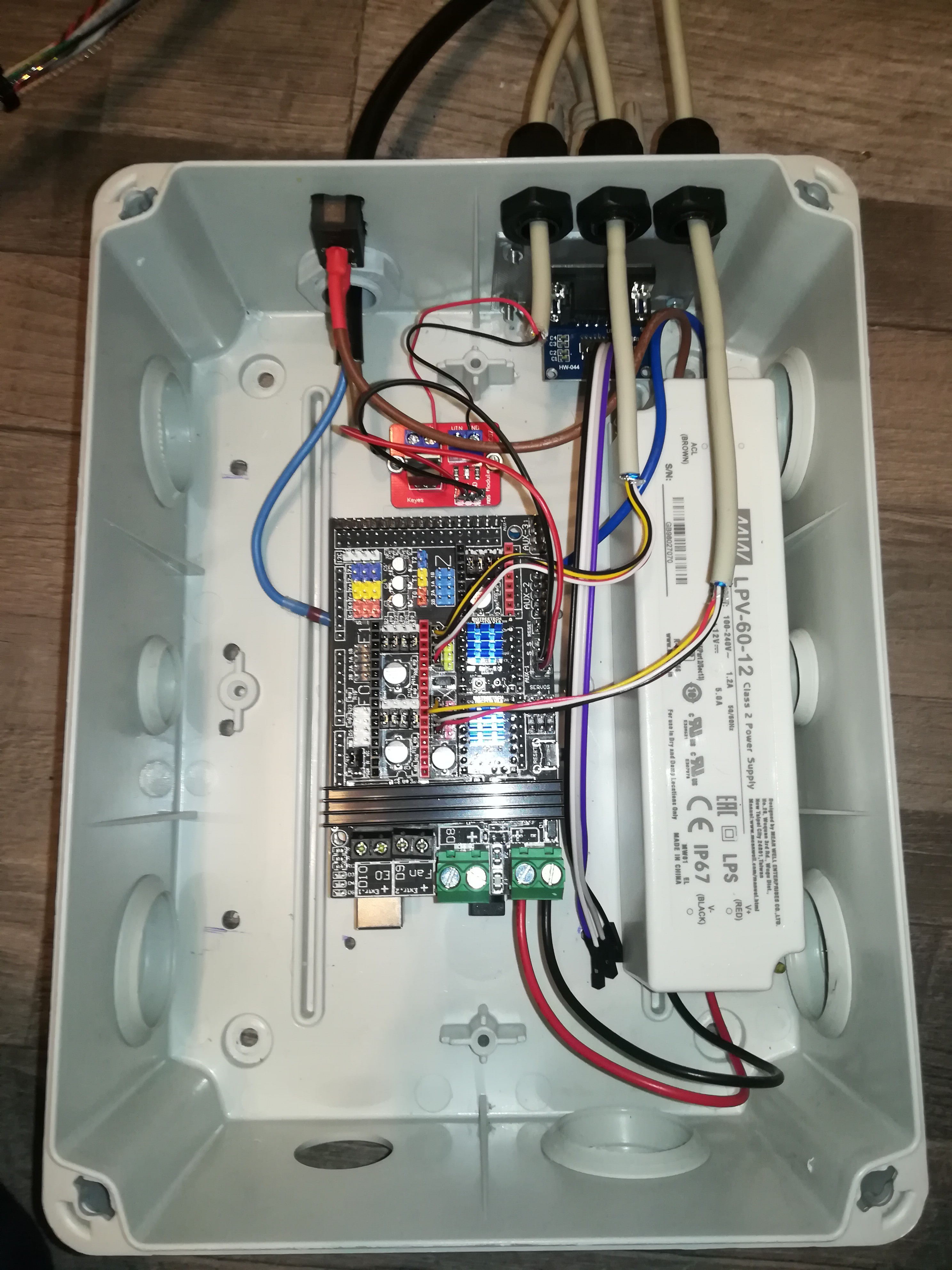

I also placed a Ramps 1.6+ & Arduino Mega 2650 with two TMC2130 and a power supply in there to control two stepper motors. A mosfet board is used to trigger the product detect.

Dominik Meffert

Dominik Meffert

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.